Melt processible fluoropolymer composition with excellent heat conductivity, molded product manufactured from the composition and manufacturing method

A melt processing, polymer technology, applied in heat exchange materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of increased melt viscosity, high melt viscosity, low thermal conductivity, etc., to achieve high insulation properties, excellent flexibility properties, excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

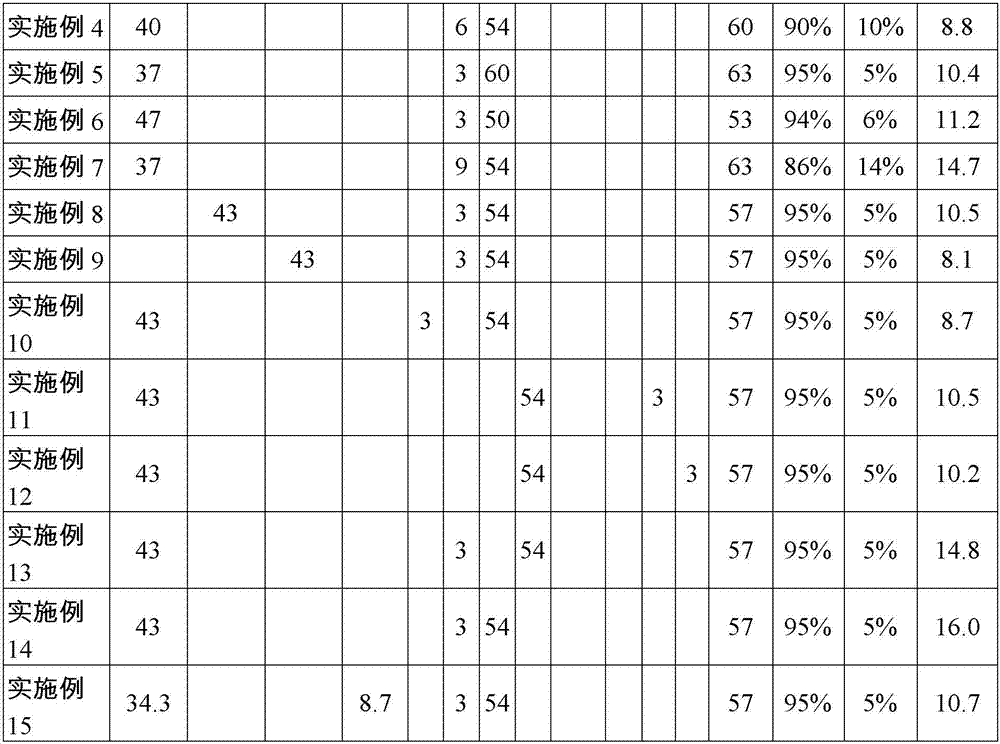

[0127] PFA1 (as a melt processable fluoropolymer), boron nitride spherical aggregate particles (A) (average particle size: 70 μm) and boron nitride spherical aggregate particles (B) (average particle size: 40 μm) were respectively Mix at a volume ratio of 43:54:3, combine so that the total amount is 30 g, and then use a coffee grinder (BC-1752J manufactured by Yamada Electric IND. Co., Ltd.) at room temperature Dry blend for 15 seconds to obtain a blended composition.

[0128] The obtained mixed composition was placed in a predetermined metal mold (dimensions: 55 mm in diameter, 30 mm in height), and after holding at 360° C. for 15 minutes, a compression molding machine (manufactured by Shinto Metal Industries Corporation) was used. hot press WFA-37, cylinder diameter: 152 mm), melt compression molding was carried out under the compression molding machine internal pressure (hydraulic pressure) of 1 MPa to obtain molded product samples. The thermal conductivity (according to m...

Embodiment 2

[0142] A composition was obtained by mixing under the same conditions as in Example 1, except that boron nitride anisotropic particles (B) (average particle diameter: 30 μm, aspect ratio: 150) were used instead of boron nitride spherical aggregates Bulk particles (B) (average particle diameter: 40 μm). The compositions were then molded, and molded articles were prepared and evaluated in the same manner. The results for the thermal conductivity of the molded article were favorable at 10.9 W / mK.

Embodiment 3

[0144] The composition was obtained by mixing under the same conditions as in Example 1, except that the amount of PFA1 was increased from 43% to 45% and the amount of boron nitride spherical aggregate particles (B) was decreased from 3% to 1%, while maintaining the amount of boron nitride spherical aggregate particles (A) at 54%. The compositions were then molded, and molded articles were prepared and evaluated in the same manner. The results for the thermal conductivity of the molded article were favorable at 10.9 W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com