Antistatic agent, antistatic agent composition, antistatic resin composition, and molding

一种树脂组合物、抗静电性的技术,应用在包装、化学仪器和方法、其他化学过程等方向,能够解决无法获得充分抗静电性能等问题,达到充分抗静电性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

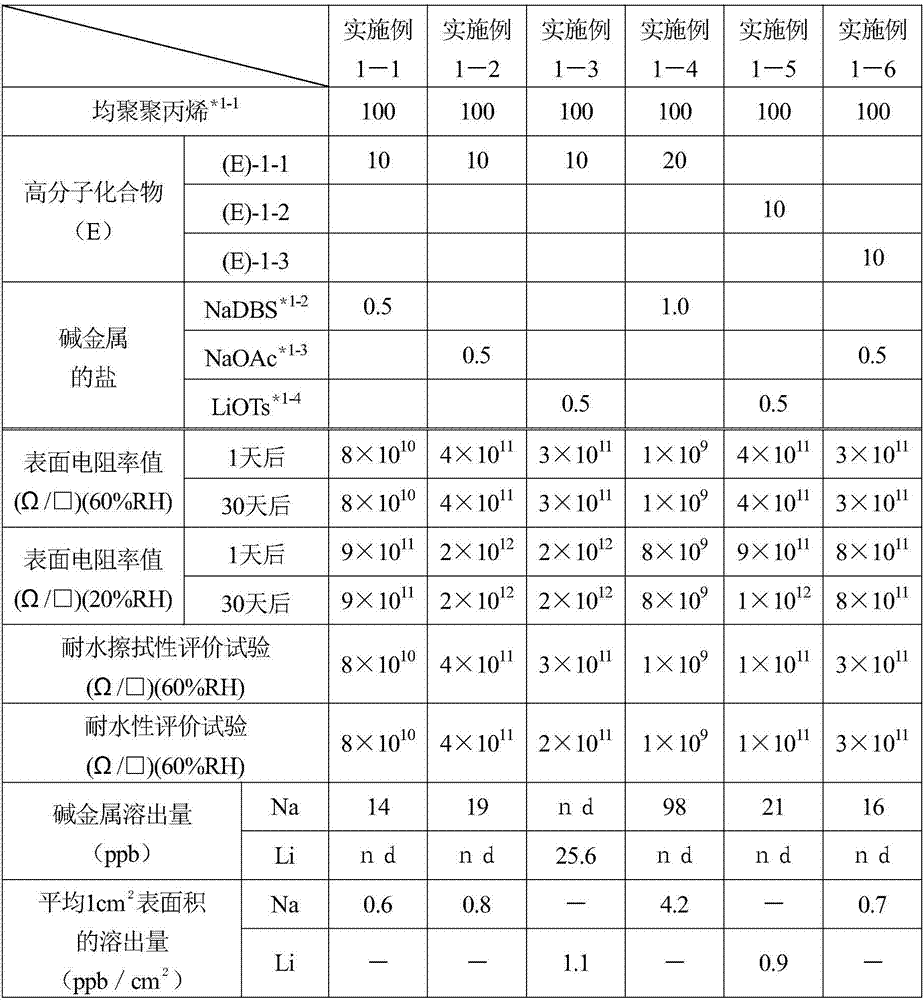

[0192] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to them. In addition, in the following examples and comparative examples, "%" and "ppb" refer to a mass basis unless otherwise specified.

[0193] According to the following Production Examples 1 to 3, the polymer compound (E) used in the present invention was produced. In addition, in the following manufacture examples 1-3, the number average molecular weight was measured by the following molecular weight measuring method.

[0194]

[0195] The number average molecular weight (hereinafter referred to as "Mn") is measured by gel permeation chromatography (GPC) method. The measurement conditions of Mn are as follows.

[0196] Device: GPC device manufactured by JASCO Corporation

[0197] Solvent: THF

[0198] Reference material: polystyrene

[0199] Detector: Differential refractometer (RI detector)

[0200] Column stationary phase: Shodex K...

manufacture example 1-1

[0206]In detachable flask, drop into 1,4-cyclohexanedimethanol 544g, adipic acid 582g (3.98 mole), phthalic anhydride 0.7g (0.01 mole), antioxidant (tetrakis[3-(3,5 -Di-tert-butyl-4-hydroxyphenyl)propionyloxymethyl]methane, ADK STAB AO-60, manufactured by ADEKA Corporation) 0.5g, while slowly raising the temperature from 160°C to 210°C, under normal pressure Polymerization was carried out for 4 hours, followed by polymerization at 210° C. under reduced pressure for 3 hours to obtain polyester (A)-1-1. The acid value of polyester (A)-1-1 was 28, and the number average molecular weight Mn was 5,400 in terms of polystyrene.

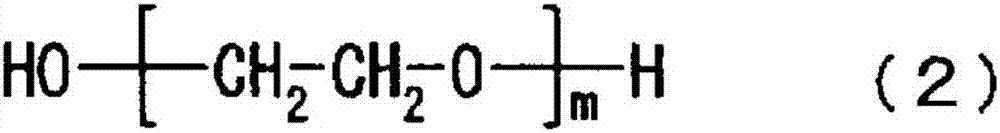

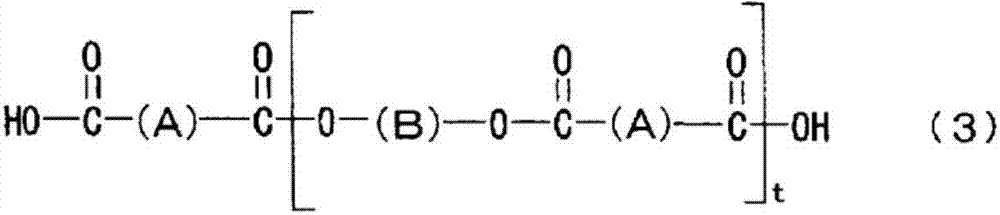

[0207] Next, 600 g of the obtained polyester (A)-1-1, 300 g of polyethylene glycol having a number average molecular weight of 4,000 as the compound (B)-1-1 having hydroxyl groups at both ends, and an antioxidant (ADK STAB AO- 60) 0.5 g and 0.8 g of zirconium octoate were polymerized at 210° C. under reduced pressure for 7 hours to obtain a block polymer (C...

manufacture example 1-2

[0210] Put 591 g of ethylene oxide adducts of bisphenol A, 235 g (1.16 moles) of sebacic acid, 8 g (0.05 moles) of isophthalic acid, and 0.5 g of antioxidant (ADK STAB AO-60) into a detachable flask , while slowly raising the temperature from 160°C to 220°C, polymerization was carried out under normal pressure for 4 hours. Thereafter, 0.5 g of tetraisopropoxy titanate was charged and polymerized at 220° C. under reduced pressure for 5 hours to obtain polyester (A)-1-2. The acid value of polyester (A)-1-2 was 56, and the number average molecular weight Mn was 2,300 in terms of polystyrene.

[0211] Next, 300 g of the obtained polyester (A)-1-2, 200 g of polyethylene glycol having a number average molecular weight of 2,000 as the compound (B)-1-2 having hydroxyl groups at both ends, and an antioxidant (ADK STAB AO- 60) 0.5 g and 0.5 g of zirconium acetate were polymerized at 220° C. under reduced pressure for 8 hours to obtain a block polymer (C)-1-2 having a structure having c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com