Back grinding tape

A back-grinding, one-side technology, used in abrasives, bulk chemical production, manufacturing tools, etc., can solve the problems of semiconductor wafer circuit damage and foreign matter attached to semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

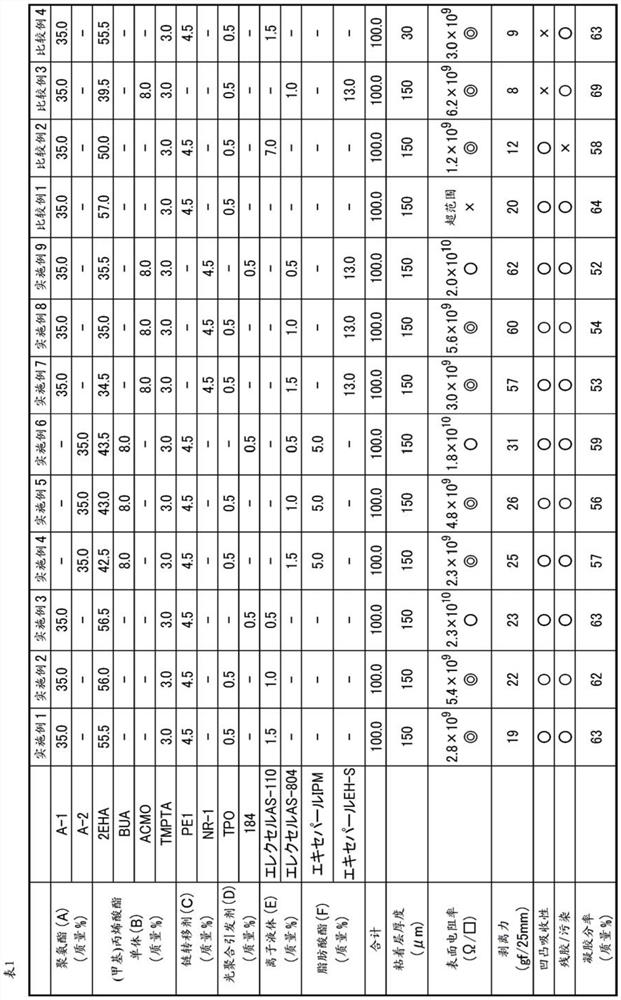

[0206] Hereinafter, the present invention will be described more concretely by way of examples and comparative examples. In addition, the present invention is not limited only to the following examples.

[0207]

[0208] In a reactor equipped with a thermometer, a stirrer, a dropping funnel, and a cooling pipe with a drying pipe, 0.55 kg of a hydrogenated product of diphenylmethane diisocyanate (Desmogluer W, manufactured by Sumika Cobestorouletan) was added ( 2.1 mol), 4.01 kg (2.0 mol) of polypropylene glycol (Actocol D-2000; produced by Mitsui Chemicals, number average molecular weight 2000) having a hydroxyl group at the end with a hydroxyl value of 56 mgKOH / g, and di Octyltin (Neostan U-810, manufactured by Nitto Kasei Co., Ltd.) 0.8 g.

[0209] Then, the temperature of the reactor was raised to 60° C. and the reaction was carried out for 4 hours to obtain a polyurethane having isocyanate groups at both terminals as a precursor of the polyurethane (A). Next, 23.22 g (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com