Tape for semiconductor processing

A semiconductor and main body technology, applied in semiconductor/solid-state device manufacturing, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor adhesion of parts, changes in physical properties of adhesives, and adjustments or changes in physical properties of adhesives over time. Suppressing difficulties and other problems to achieve the effect of sufficient antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0209]

[0210] 9.4 parts by mass of polypyrrole dispersion (PPY-12 manufactured by Maruhi Oil & Chemical Industry Co., Ltd., solid content 8%), polyester-based binder (BI-12 manufactured by Maruhi Oil & Chemical Industry Co., Ltd., solid content 30%) ) 5.0 parts by mass, 2.6 parts by mass of a melamine-based crosslinking agent (CL-12 manufactured by Maruhi Oil Chemical Industry Co., Ltd., solid content 25%), 0.05 parts by mass of polyoxyethylene lauryl ether, and 830.0 parts by mass of water to prepare water Dispersions. Next, as a substrate main body, a 50 μm-thick PET film (manufactured by Toyobo Co., Ltd., trade name: Esther (trademark) film E5100) was coated with a gravure coater so that the film thickness after heat curing became 1.0 μm. The resin composition is applied. Next, the sheet-like base material 1 was obtained by performing hardening at 130 degreeC for 1 minute. The resistance of the base material 1 measured by a low resistivity meter (Rolesta-AX manufactur...

Synthetic example 1

[0215]

[0216] In a reactor equipped with a thermometer, a stirrer, a dropping funnel, and a cooling tube with a drying tube, 0.55 kg (2.1 kg) of a hydrogenated product of diphenylmethane diisocyanate (Destroy W, manufactured by Sumika Co., Ltd.) mol), 4.01 kg (2.0 mol) of polypropylene glycol having a hydroxyl group at the terminal with a hydroxyl value of 56 mgKOH / g (Actoko D-2000; manufactured by Mitsui Chemicals, number average molecular weight 2000), and dioctyltin as a urethane catalyst (ネオスタン U-810, manufactured by Nitto Chemical Co., Ltd.) 0.8 g.

[0217] Then, the temperature of the reactor was raised to 60° C. and the reaction was carried out for 4 hours to obtain a polyurethane having isocyanate groups at both ends as a precursor of the polyurethane (A). Next, 23.22 g (0.2 mol) of 2-hydroxyethyl acrylate was added to the reactor, and the temperature was raised to 70° C. and reacted for 2 hours to obtain 4.58 kg of polyurethane (A-1) having a mass average molecula...

Synthetic example 2

[0220]

[0221] The method for synthesizing polyurethane (A-1) was the same as the method for synthesizing polyurethane (A-1), except that 2.1 mol of isophorone diisocyanate (Destroyd I, manufactured by Sumina Chemical Co., Ltd.) was used instead of the hydrogenated product of diphenylmethane diisocyanate. By operation, polyurethane (A-2) having a mass average molecular weight of 66,000 was obtained.

[0222] The obtained polyurethane (A-2) was analyzed by infrared absorption spectroscopy (IR). As a result, the peak derived from the isocyanate group was not observed. Therefore, it was confirmed that the urethane (A-2) was the urethane (a1) in which acryloyloxy groups were introduced into all the terminals.

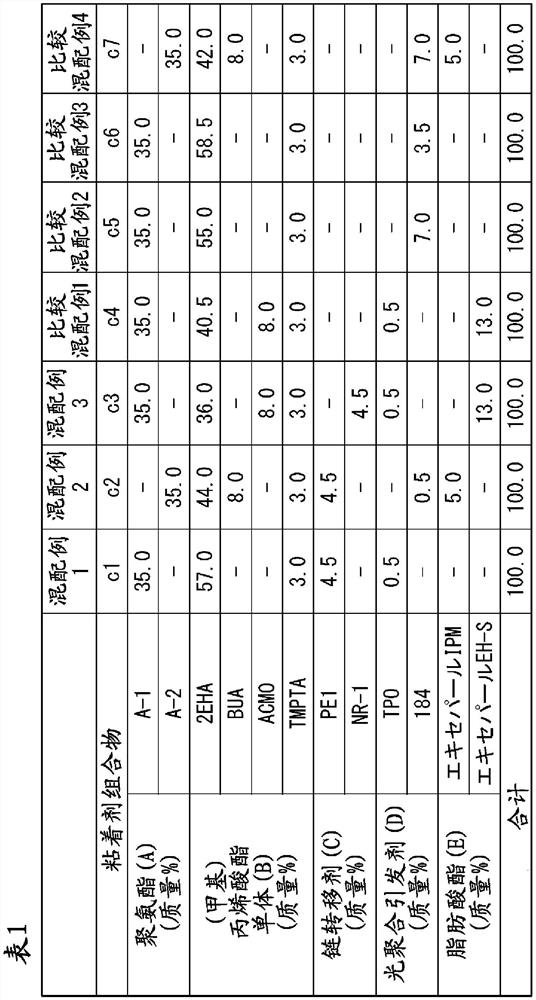

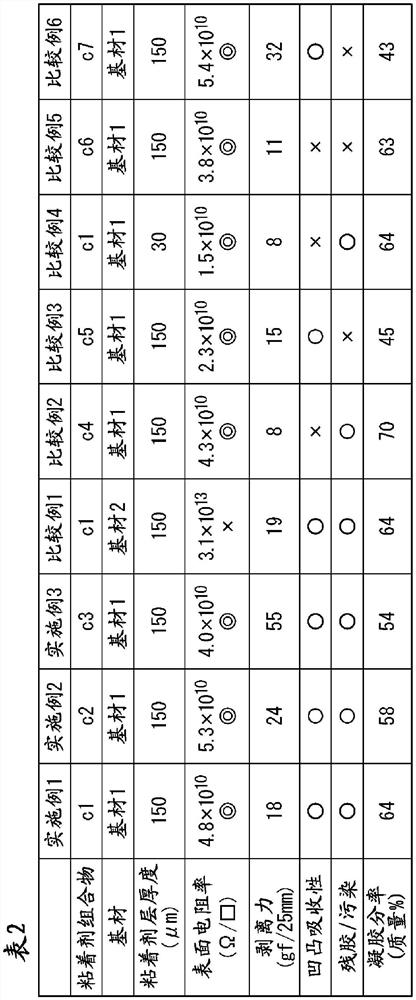

[0223] (Compounding Examples 1 to 3, Comparative Compounding Examples 1 to 4)

[0224]

[0225] The polyurethane (A) obtained by the above-mentioned synthesis method, the (meth)acrylate monomer (B) shown in Table 1, the chain transfer agent (C), the photopolymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com