Peeling film for green sheet formation

A technology of peeling film and green sheet, applied in ceramic molding machines, synthetic resin layered products, film/sheet release liner, etc. Sufficient antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0035] Hereinafter, the present invention will be described by taking the embodiments as examples. The present invention is not limited to the contents of the embodiments.

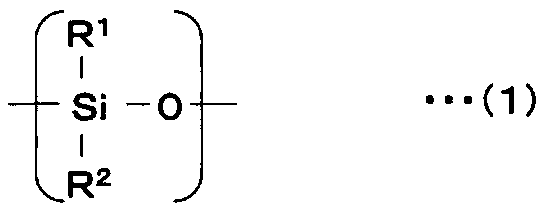

[0036] In 1st Embodiment, the case where (A1) energy-beam curable compound was used as (A) curable compound in the material for release agent formation is mentioned as an example and demonstrated.

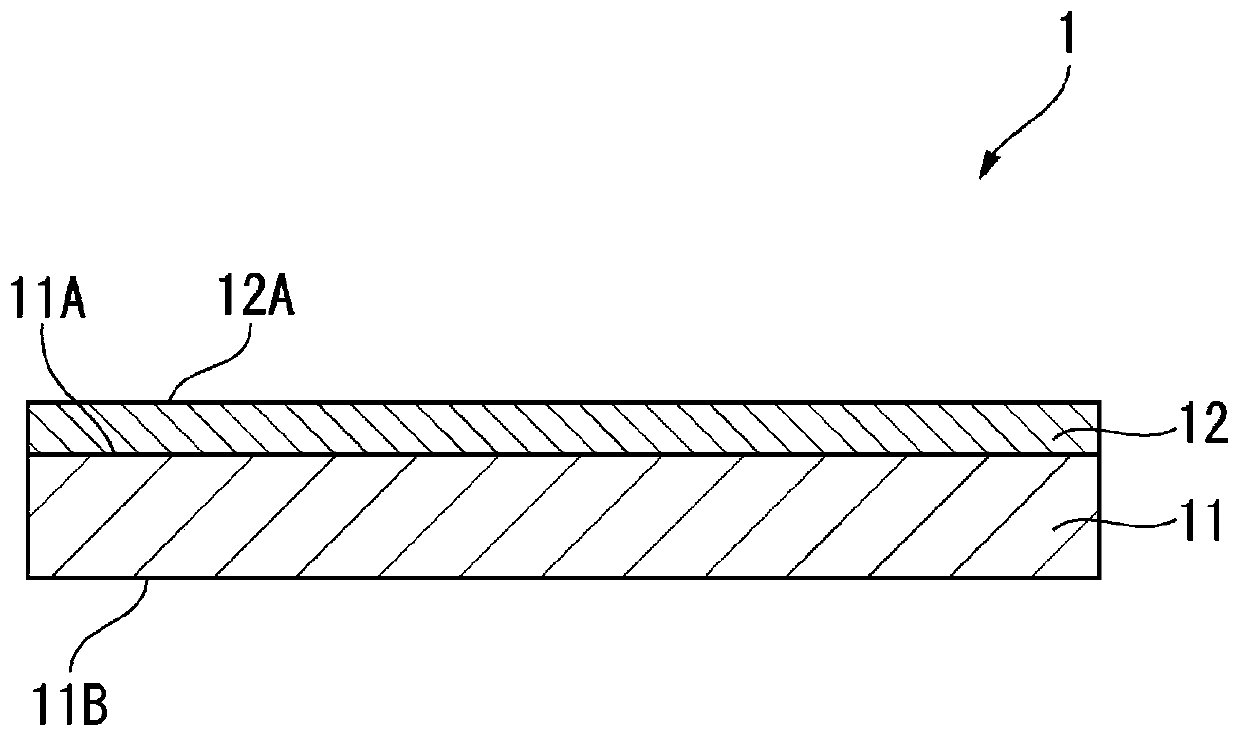

[0037] The release film 1 for green sheet formation of this embodiment (hereinafter "release film 1") is as follows: figure 1 As shown, base material 11 and release agent layer 12 provided on first surface 11A of base material 11 are provided.

[0038] (Substrate)

[0039] The base material 11 of the present embodiment has a first surface 11A and a second surface 11B.

[0040] The material constituting the substrate 11 is not particularly limited, and examples thereof include polyester resins (polybutylene terephthalate resins, polyethylene terephthalate resins, and polyethylene naphthalate resins). ester r...

no. 2 approach

[0132] Next, a second embodiment of the present invention will be described.

[0133] In 2nd Embodiment, the case where (A2) thermosetting compound was used as (A) curable compound in the material for release agent formation is mentioned as an example and demonstrated.

[0134] In addition, in this embodiment, except using (A2) thermosetting compound as (A) curable compound, it is the same as above-mentioned 1st embodiment, therefore, for the release agent layer containing (A2) thermosetting compound The materials for formation and their usage methods will be described, and other descriptions will be omitted or simplified.

[0135] (Material for release agent layer formation)

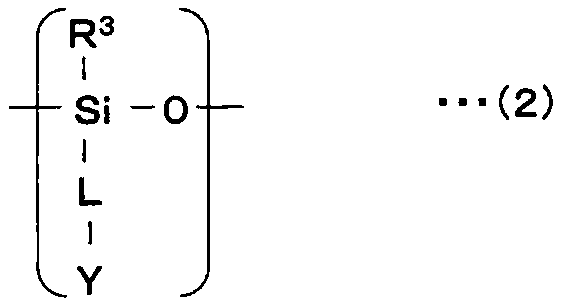

[0136] The release agent layer forming material of this embodiment contains (A2) a thermosetting compound and (B) an ionic group-containing organosilicon compound.

[0137] The (B) ionic group-containing organosilicon compound of this embodiment is the same as the (B) ionic group-containing organosili...

Embodiment 1

[0196] First, a polyethylene terephthalate film (trade name "Lumirror U48", manufactured by Toray Co., Ltd., thickness: 50 μm, arithmetic mean roughness Ra (Ra 1 ): 2nm, the maximum protrusion height Rp on the first surface (Rp 1 ): 15nm, the arithmetic mean roughness Ra of the second surface (Ra 2 ): 2nm, the maximum protrusion height Rp on the second surface (Rp 2 ): 15nm).

[0197] Next, 100 parts by mass of an energy ray-curable compound, 5 parts by mass of an ionic group-containing organosilicon compound, and 10.5 parts by mass of a photopolymerization initiator were mixed and diluted with isopropanol to obtain a compound with a solid content of 15% by mass. Material for forming a release agent layer.

[0198] Next, the obtained release agent layer-forming material was applied on the first surface of the substrate with a Meyer rod, dried at 70° C. for 1 minute, and then irradiated with ultraviolet light (cumulative light intensity: 300 mJ / cm2) using a high-pressure mer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com