Seal member for joint of machine and method of assembling same

A technology of sealing components and components, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as increased mechanical load, poor operation efficiency of lifting cylinders, and poor bearing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

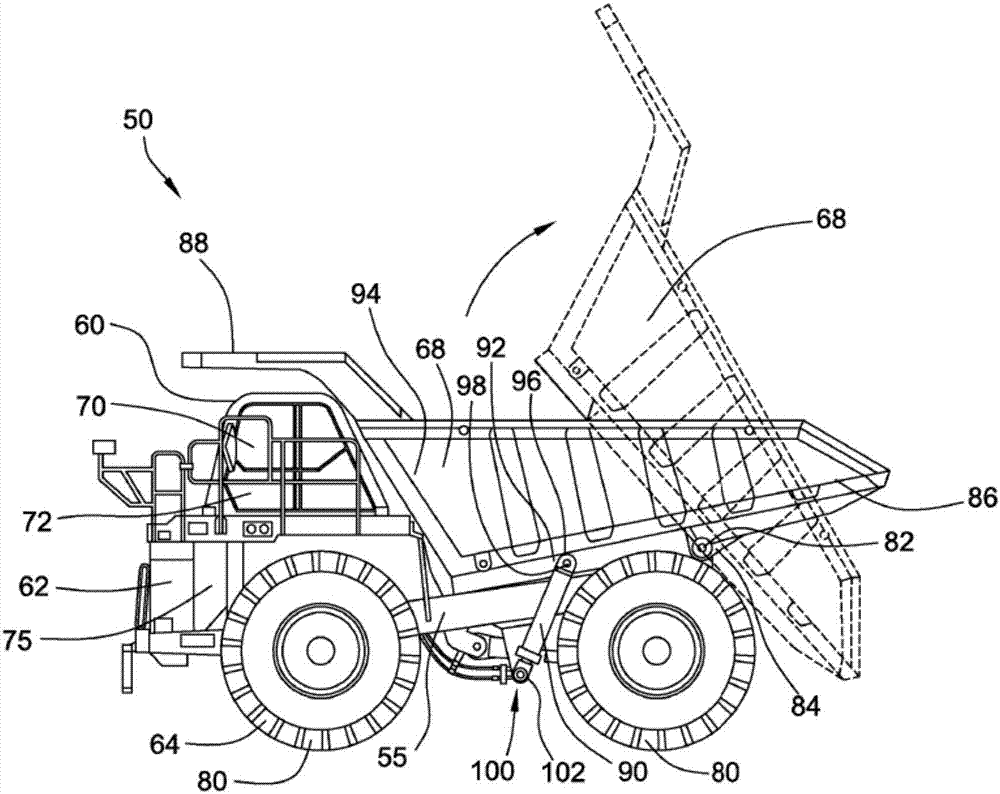

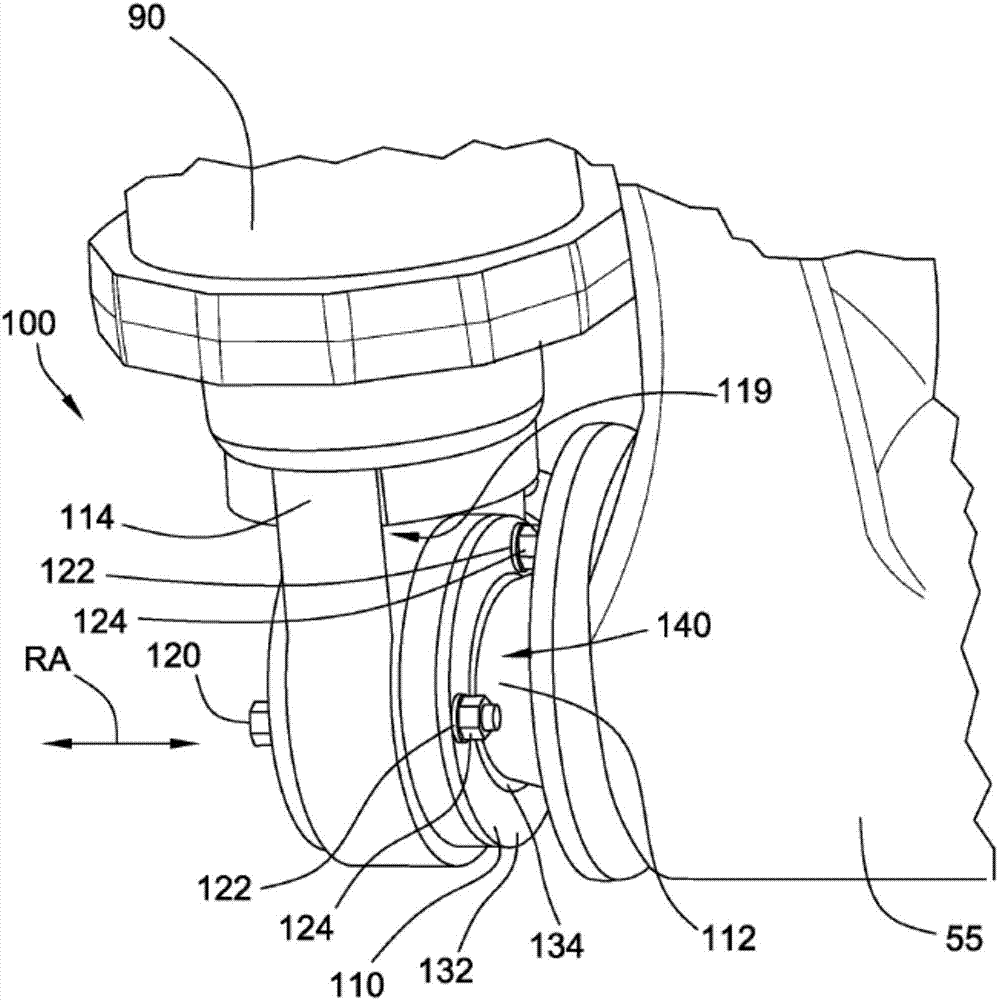

[0034] The present invention generally relates to a joint assembly of a machine. In an embodiment, the invention relates to a sealing member for a joint assembly of a machine. In an embodiment, the invention relates to a seal member for a maintenance-free bearing of a joint assembly of an off-highway machine. In an embodiment, the invention relates to a method of assembling a joint of a machine.

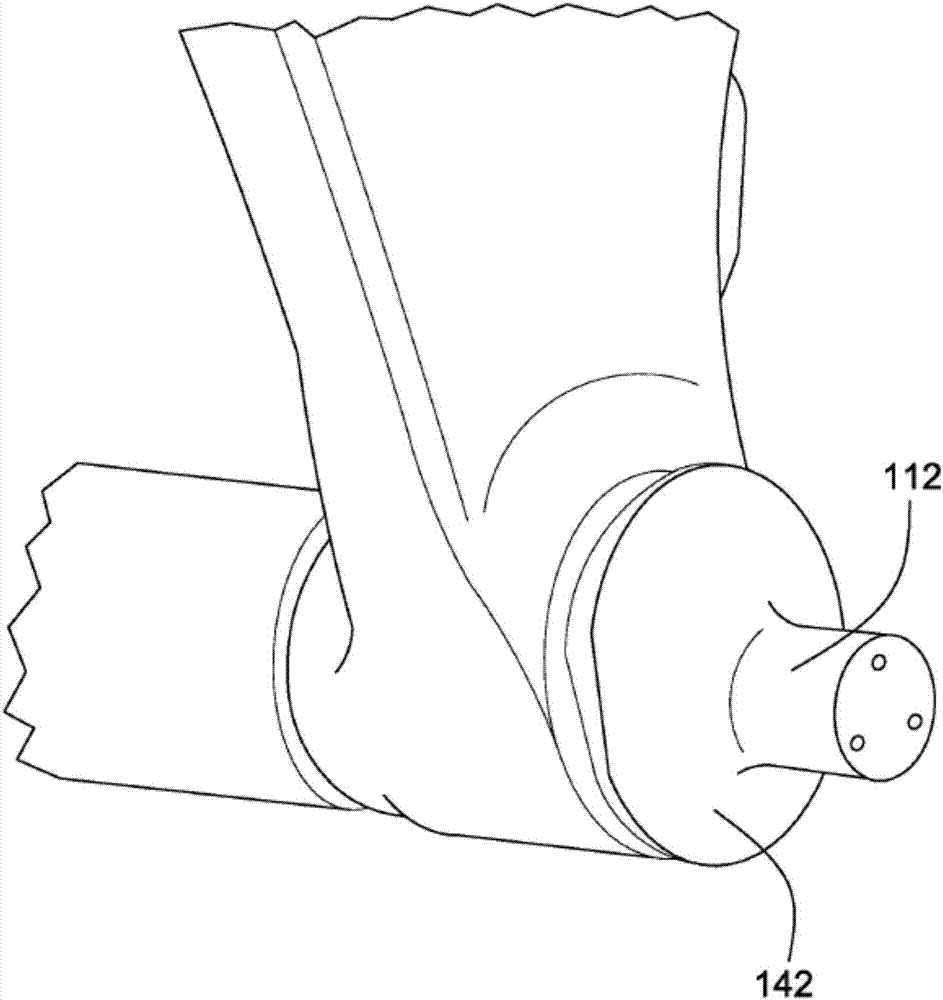

[0035] In an embodiment, a sealing member is provided for a joint between pivot members movable about an axis of rotation of a shaft. The sealing member may include a ring, a flange, and an elastically bendable intermediate portion interposed between the ring and the flange. In an embodiment, both the ring and the flange are more rigid than the middle part.

[0036] In an embodiment, the joint assembly includes a shaft defining an axis of rotation, a pivot member mounted relative to the shaft, the pivot member being pivotable relative to the shaft about the axis of rotation, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com