Valve device in a motor vehicle, and production method

A valve device and motor vehicle technology, applied in the field of manufacturing, can solve problems such as high cost and complicated valve device structure, and achieve the effect of low leakage rate and long-lasting sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

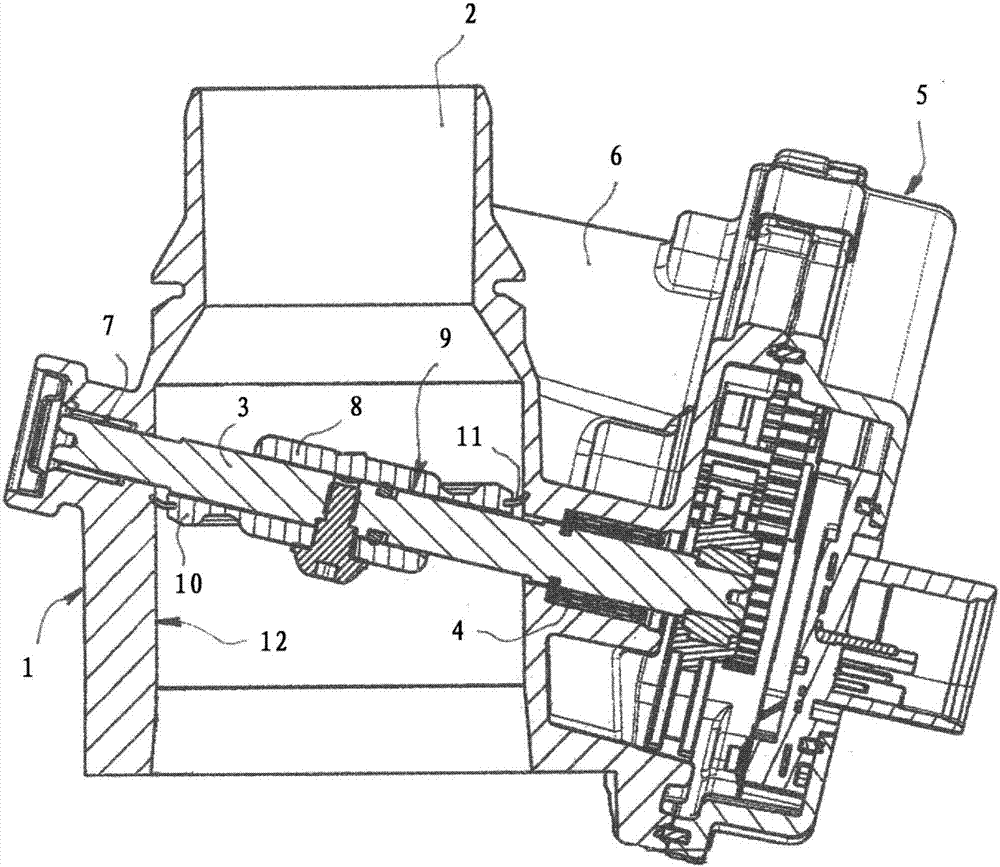

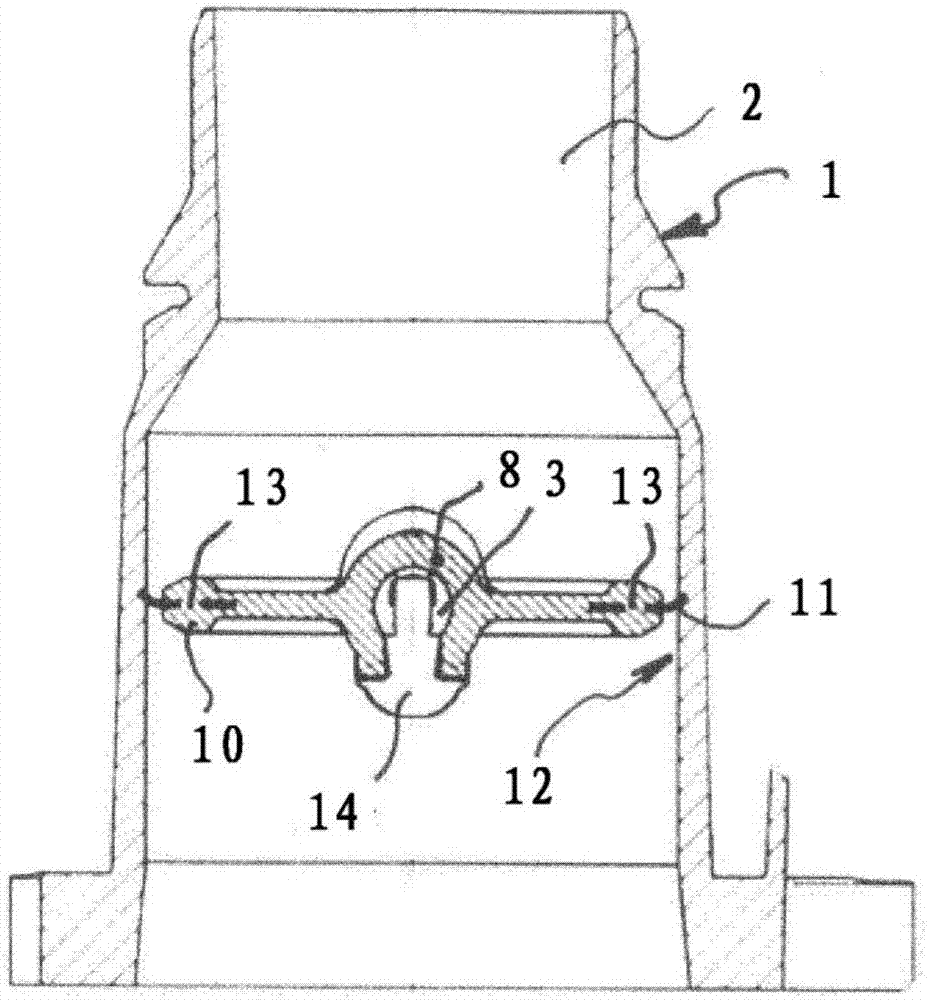

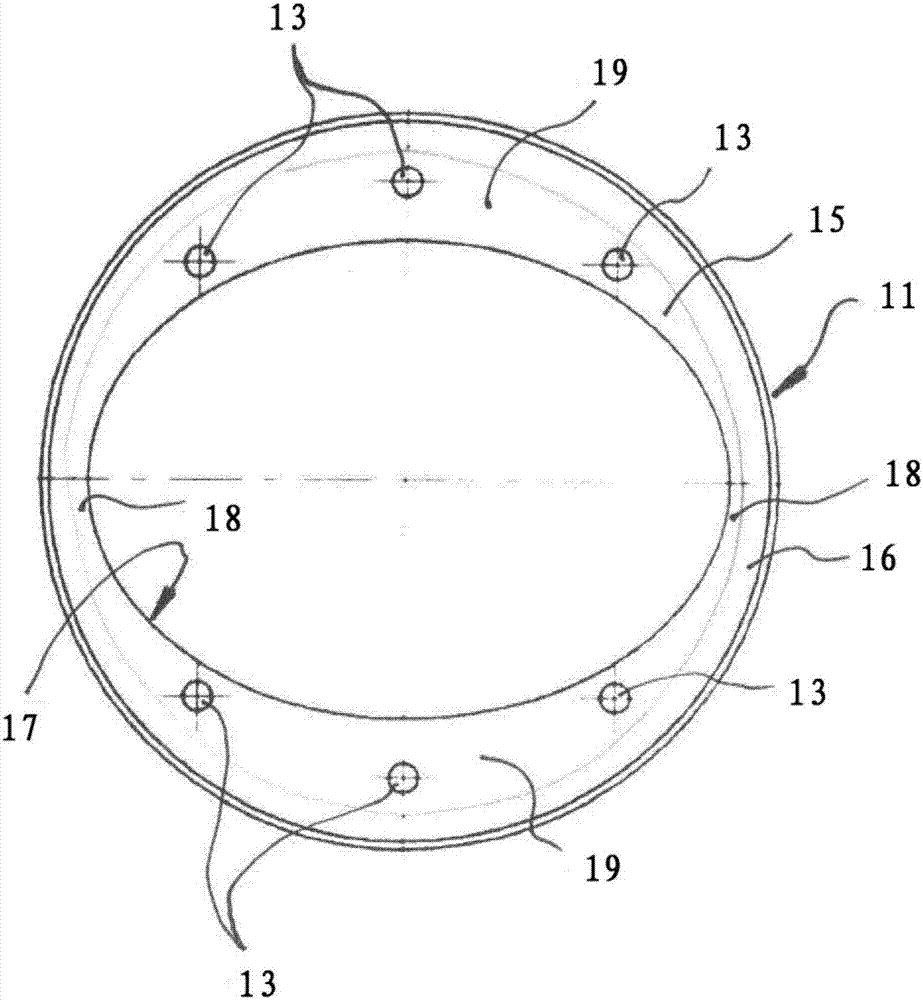

[0026] figure 1 The valve arrangement for a motor vehicle in ® consists of a housing 1 with a flow channel 2 arranged in the housing for the flow of a fluid. In the present case, the air flow is regulated by means of valve means. Arranged in the flow channel 2 is a shaft 3 , which is supported on both sides in the housing 1 . The first bearing 4 is located on that side of the housing 1 on which the transmission 5 is arranged. The transmission 5 is connected on the output side to the shaft 3 and on the input side to an electric motor, not shown, which is accommodated in a separate chamber 6 of the housing 1 . The second bearing 7 for the shaft 3 is located on the side of the flow channel 2 opposite the transmission 5 . Arranged on the shaft 3 is a flap 8 which has a bore 9 through which the shaft 3 extends. In order to be fixed on the shaft 3, the disc 8 is screwed to the shaft 3. The valve flap 8 also has a circumferentially surrounding edge 10 on which a seal 11 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com