Sealed aerated grit chamber

A technology for aerated grit chambers and grit chambers, applied in the field of aerated grit chambers, can solve the problems of unsealed top of the pool, limited space, poor effect, etc., saving upper space, no scraping dead zone, The effect of reducing odor leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

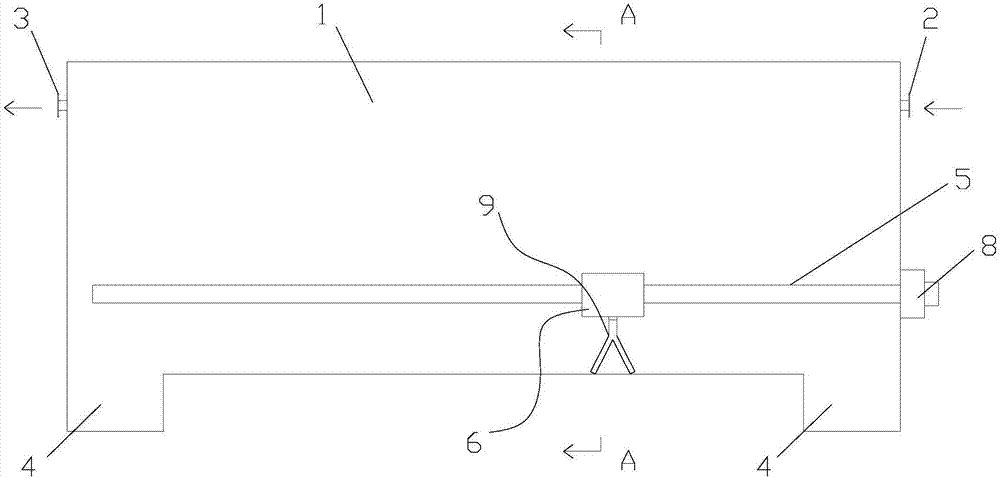

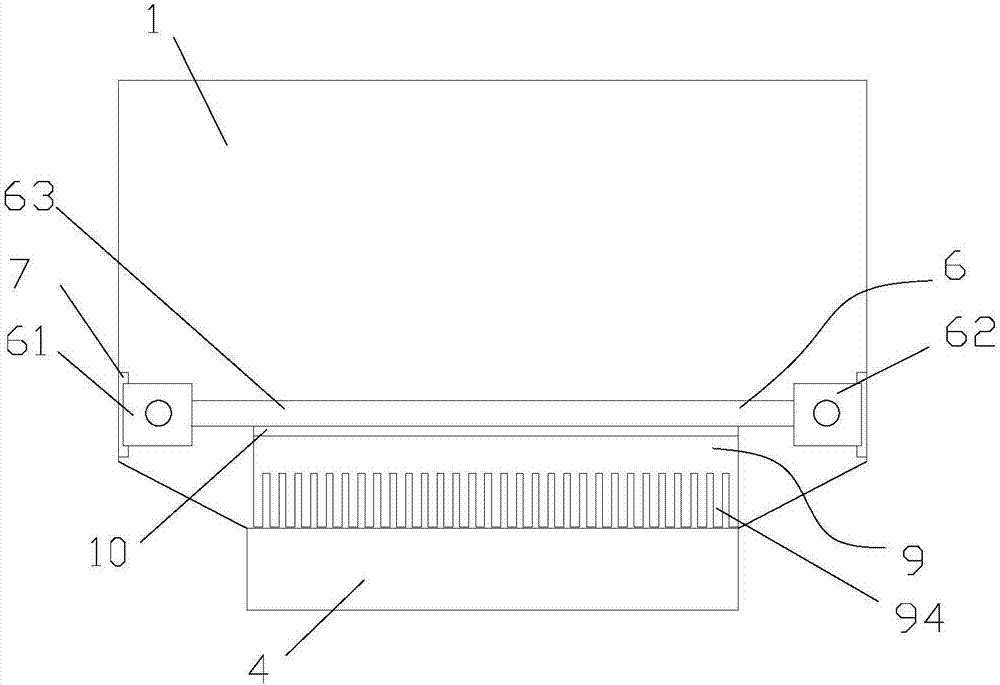

[0026] Such as figure 1 , 2 , 3, a kind of closed aerated grit chamber provided by the present invention comprises grit chamber 1, sand scraping mechanism; Said grit chamber 1 is a closed box structure, one end is provided with water inlet 2, and the other end is provided with There is a water outlet 3; both ends of the bottom of the grit chamber 1 are provided with sand collecting parts 4. The top of the grit chamber 1 is fully sealed to reduce the leakage of odor.

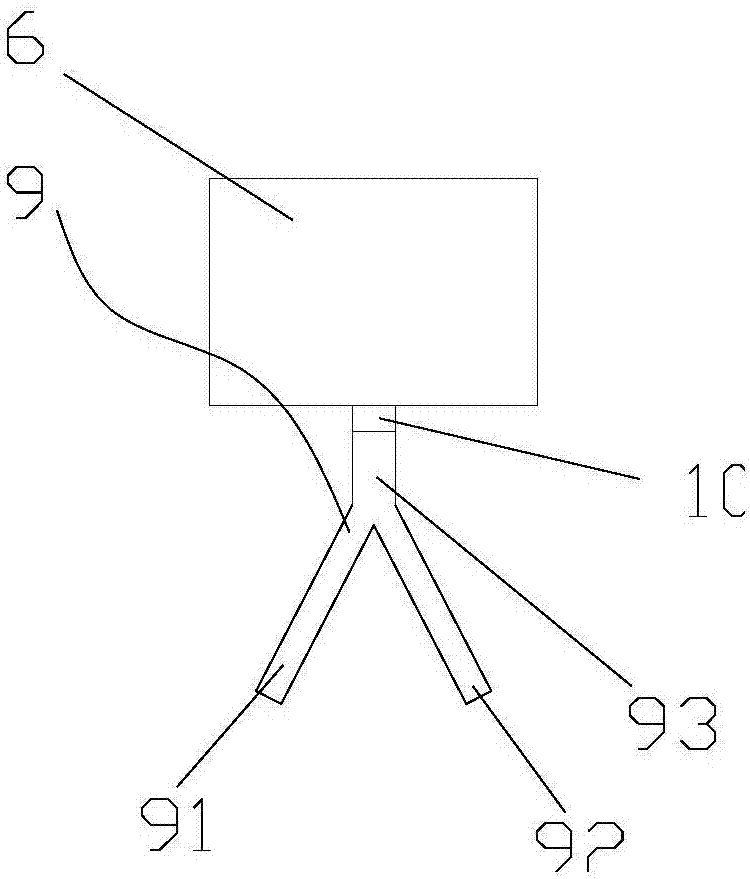

[0027] The sand scraping mechanism is arranged at the bottom of the grit chamber 1, and the sand scraping mechanism includes a rotating part 5 extending along the length direction of the grit chamber 1, a moving part 6 and a scraper 9 arranged on the rotating part 5; The rotation of the part 5 can drive the moving part 6 to move in the length direction of the grit chamber 1; the scraper 9 is installed on the moving part 6 and moves together with the moving part 6 to scrape the sand at the bottom of the grit cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com