Four-freedom-degree spherical module unit

A technology of modular units and degrees of freedom, applied in the directions of manipulators, joints, program-controlled manipulators, etc., can solve the problems of few degrees of freedom configuration, weak flexibility, low space utilization, etc., to promote development, improve utilization, and utilization. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

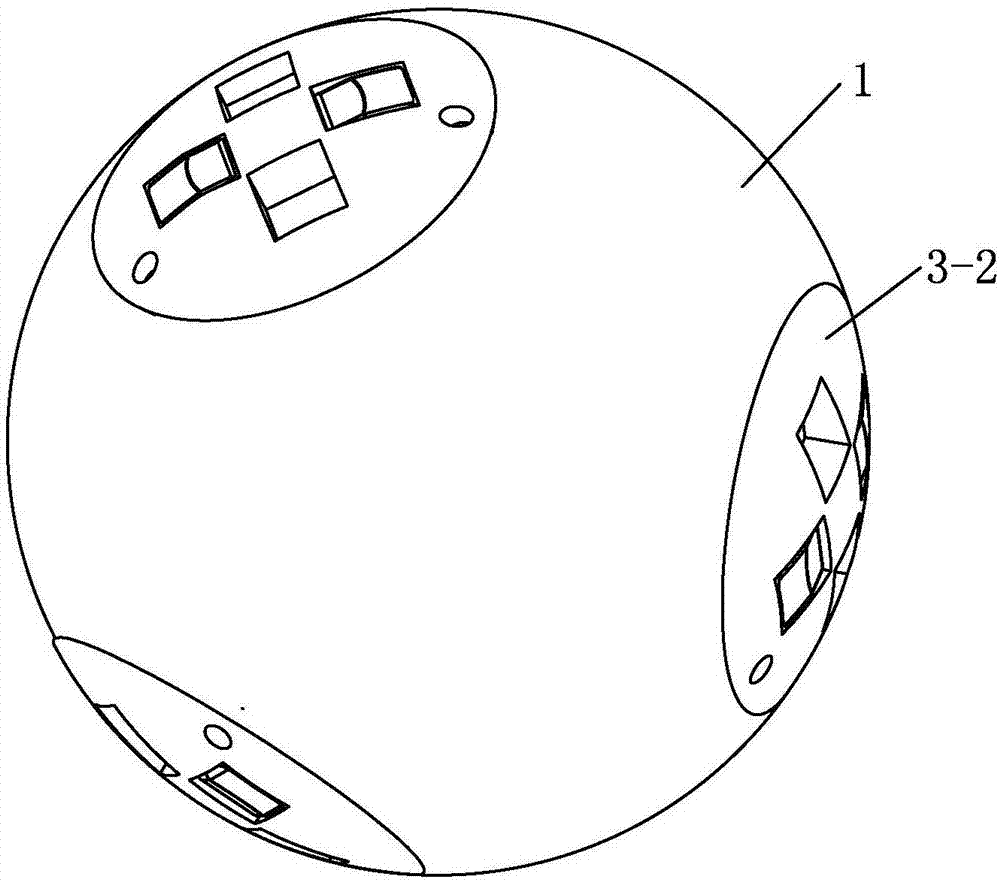

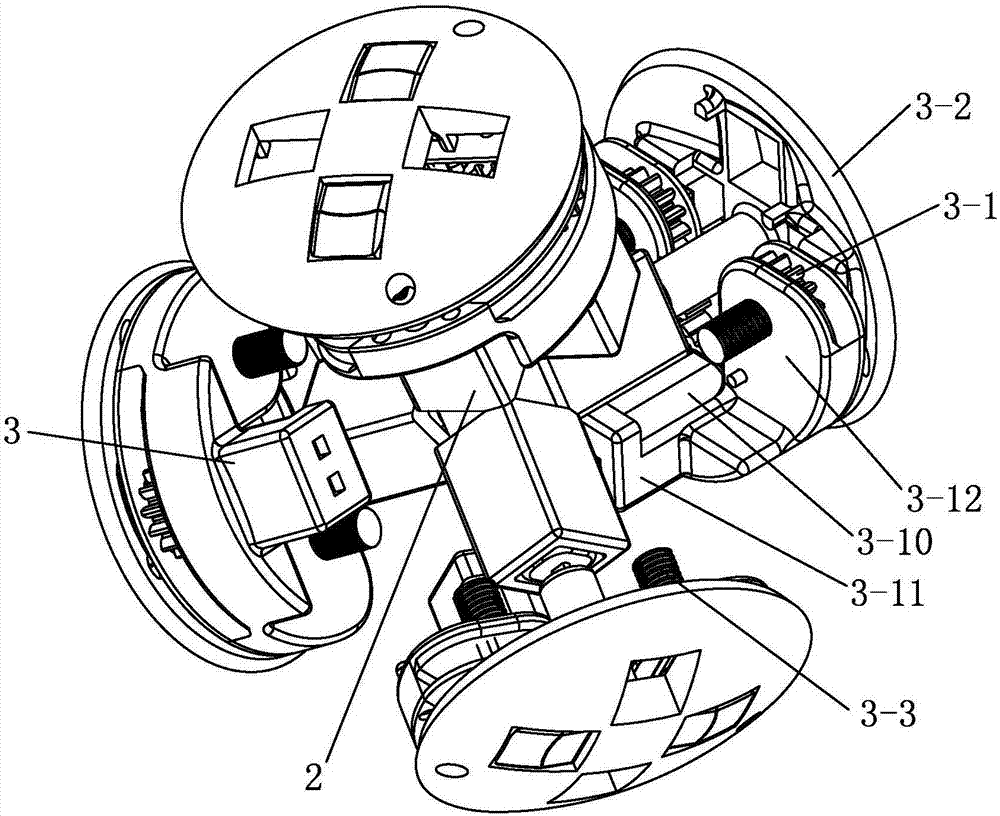

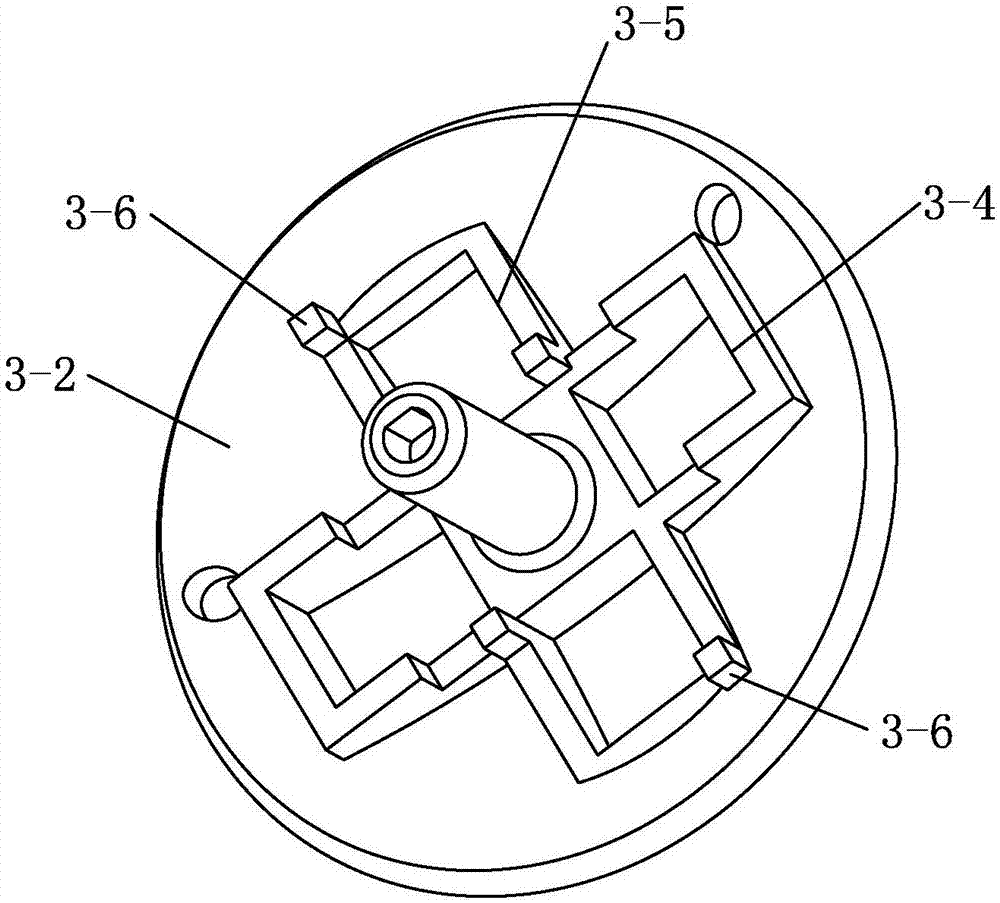

[0033] see Figure 1-Figure 4 Description, a four-degree-of-freedom spherical modular unit of the present embodiment, which includes a spherical shell 1, a regular tetrahedral assembly and four sets of connecting assemblies 3; the regular tetrahedral assembly includes a regular tetrahedral support 2 and four drive motors 4; each The sleeve connection assembly 3 includes a transmission mechanism 3-1, a housing 3-2 and two lifting mechanisms 3-3;

[0034] A regular tetrahedral bracket 2 and four sets of connecting components 3 are arranged inside the spherical shell 1. There are four mounting seats on the regular tetrahedral bracket 2, and the four mounting seats form the vertices of the regular tetrahedron. Each mounting seat is equipped with a drive Motor 4, a housing 3-2 is installed on the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com