Automatic equal-distance building wood cutting device

A technology of equidistant cutting and wood, which is applied in the direction of wood processing equipment, forming/shaping machines, manufacturing tools, etc. It can solve the problems of affecting the health of cutting personnel, unable to meet equidistant cutting, and cutting can not be stable, etc., to achieve increased friction Resistance, preventing flying everywhere, avoiding the effect of cutting too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

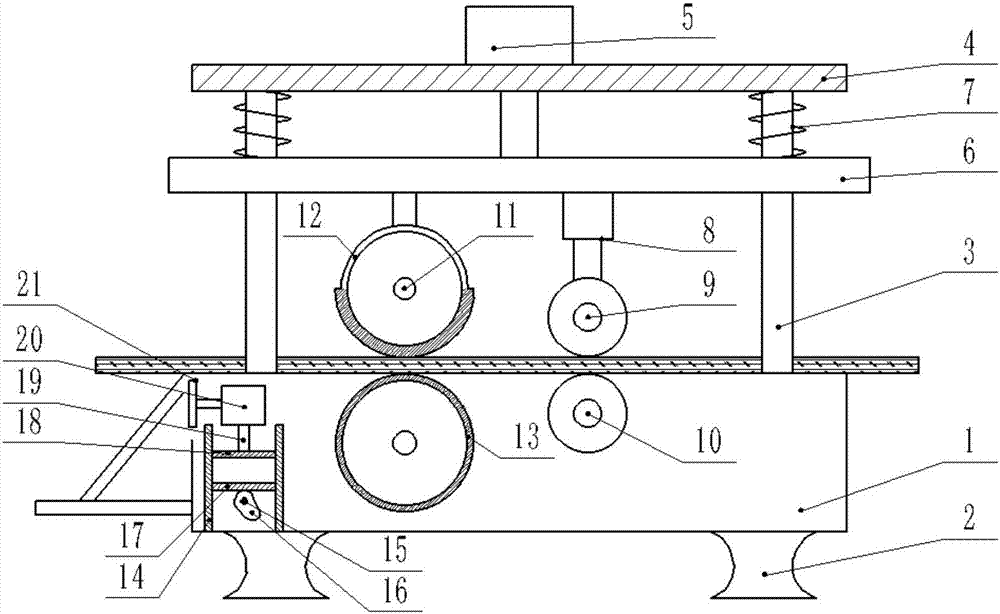

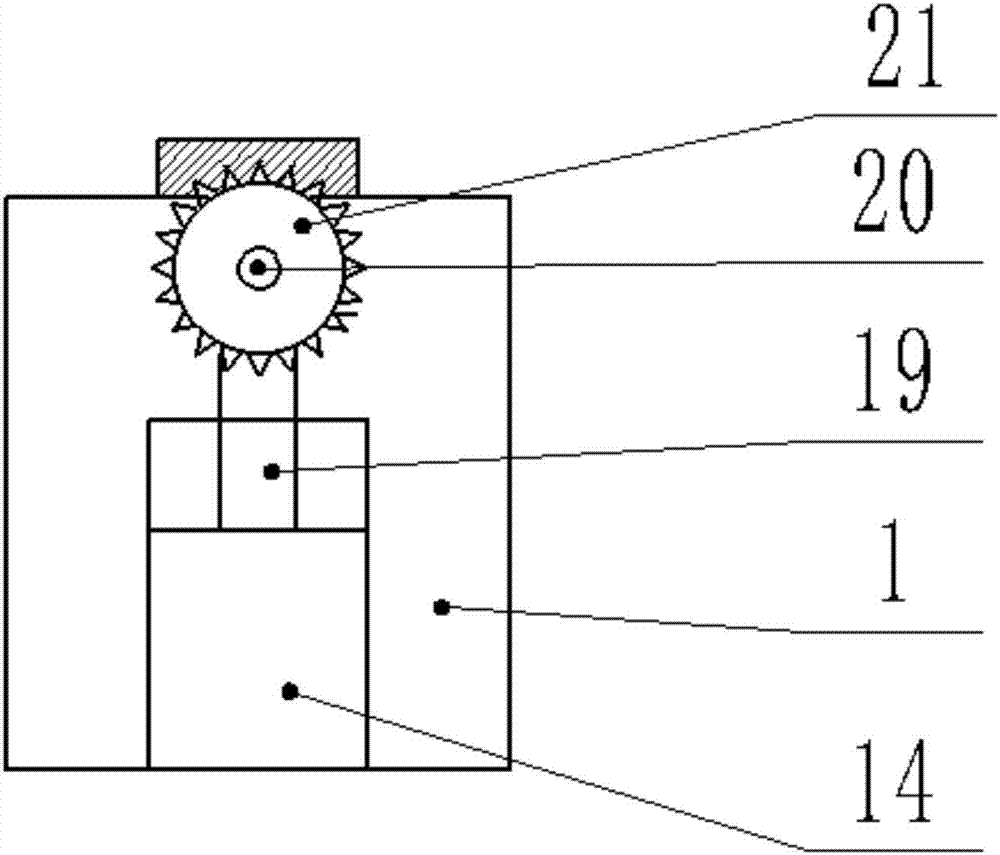

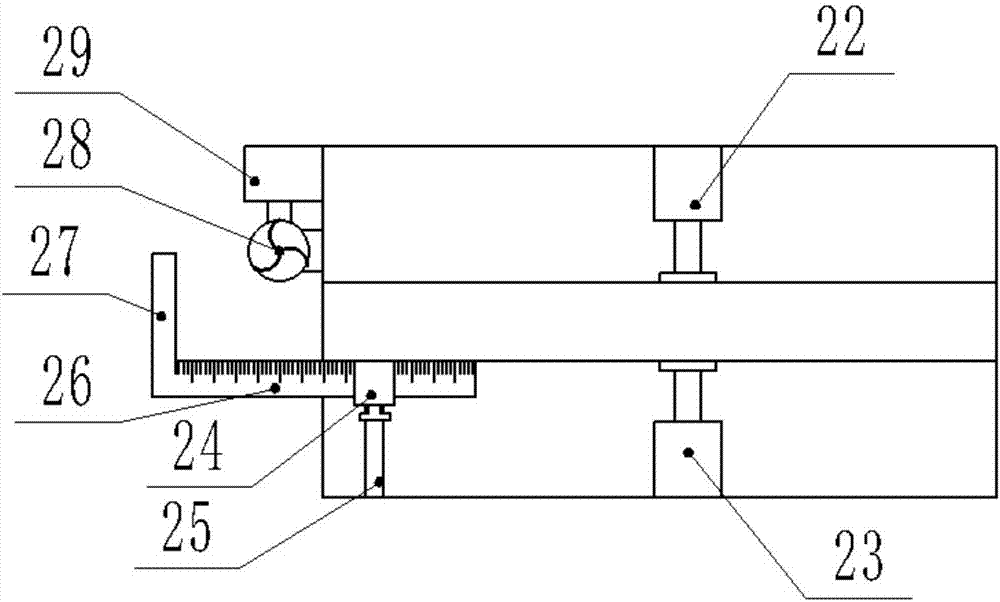

[0019] see Figure 1-2 , an automatic equidistant cutting device for building timber, comprising a cutting table 1, a top plate 4, a driving roller 12, a lifting device 14, a cutting motor 20, a cutting wheel 21, a scale 26 and a debris collection device 29, the cutting table 1 The interior is a hollow structure, and at least two sets of support legs 2 are fixedly installed on the lower side of the cutting table 1, and the support round rods 3 are symmetrically installed on the left and right sides of the upper surface of the cutting table 1, and the support round rods 3 are fixedly installed on the cutting table 1 through threads. A top plate 4 is fixedly installed on the upper end of the support round rod 3, and a hydraulic machine A5 is fixedly installed at the center of the top plate 4. The output shaft of the hydraulic machine A5 goes vertically downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com