Position control method of compression layer for wood laminated compression

A control method and compression layer technology, which is applied to wood processing appliances, wooden veneer joints, veneer presses, etc., can solve problems such as how to control the compression layer without explaining, so as to improve the performance and price of use, and resist Effects of increased flexural strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

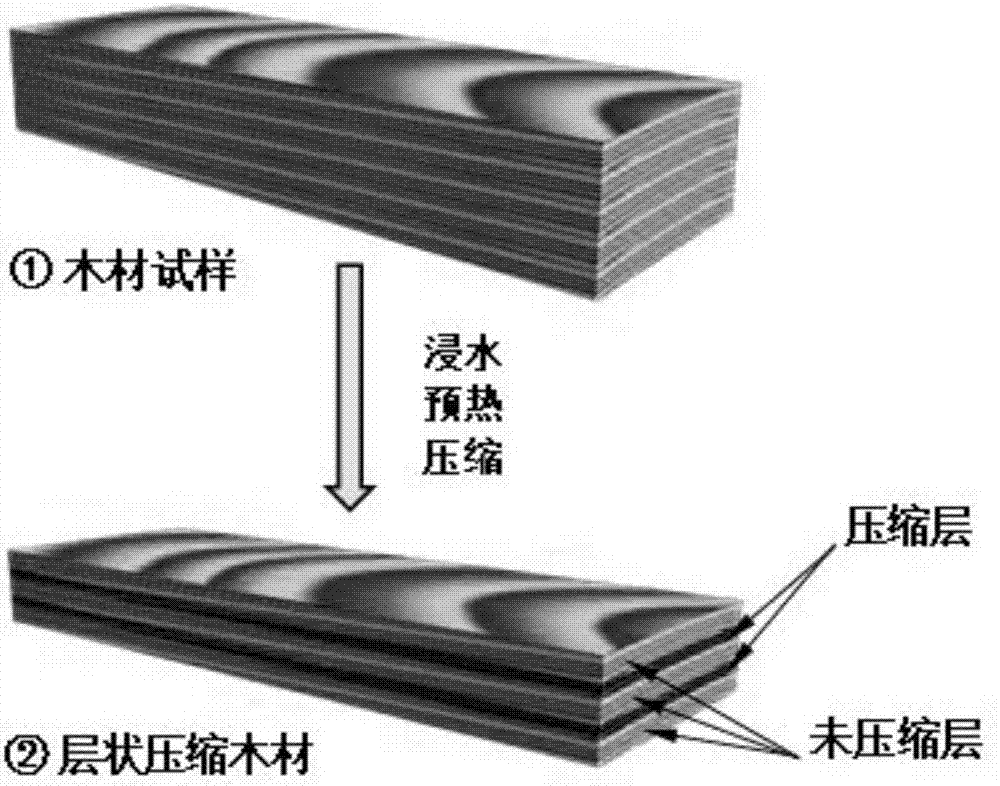

[0024] Embodiment 1: the compression layer position control method of wood laminar compression, as attached figure 1 As shown, the method specifically includes the following specific steps:

[0025] 1) Seal or soak the wood according to the difference in moisture content;

[0026] For wood with a moisture content below 14%, use hydrophobic materials such as paraffin for end-sealing treatment, and then soak in room temperature water or hot water below 100°C, or soak directly without end-sealing, for 10 minutes to 6 hours, preferably 30 minutes to 3 hours, preheating after soaking; wood with a moisture content of 14% to 30% can be preheated directly, or soaked for a short time, and preheated after soaking for 30 minutes to 3 hours treatment; wood with a moisture content greater than 30% is directly used for subsequent preheating treatment;

[0027] 2) Put the wood on a press that is preheated to 70-250°C (that is, heat the briquette of the press to 70-250°C first), and the pre...

Embodiment 2

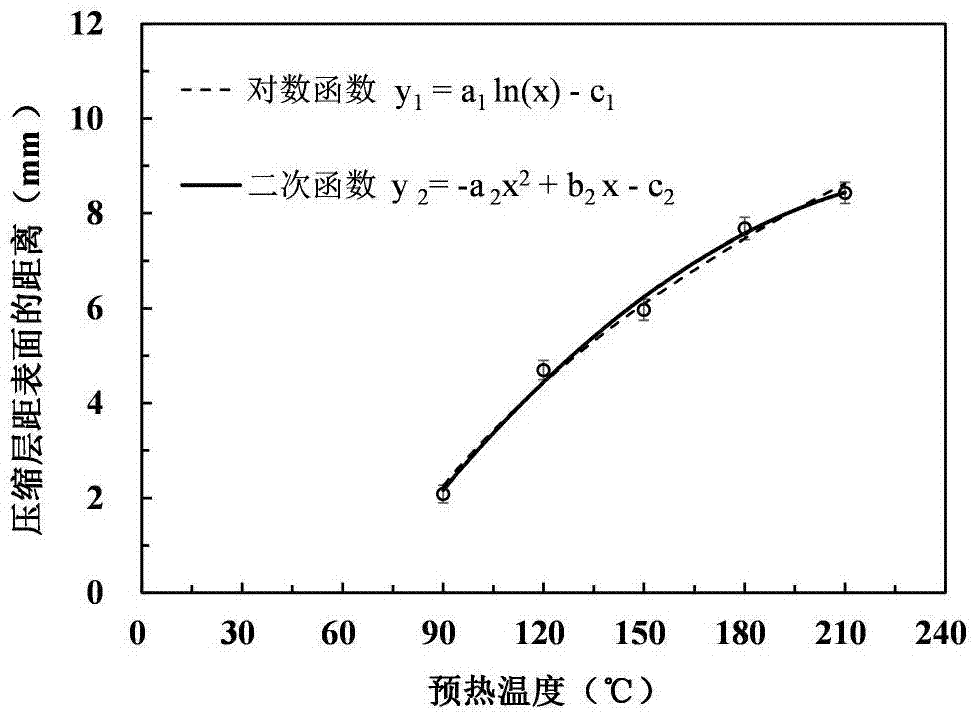

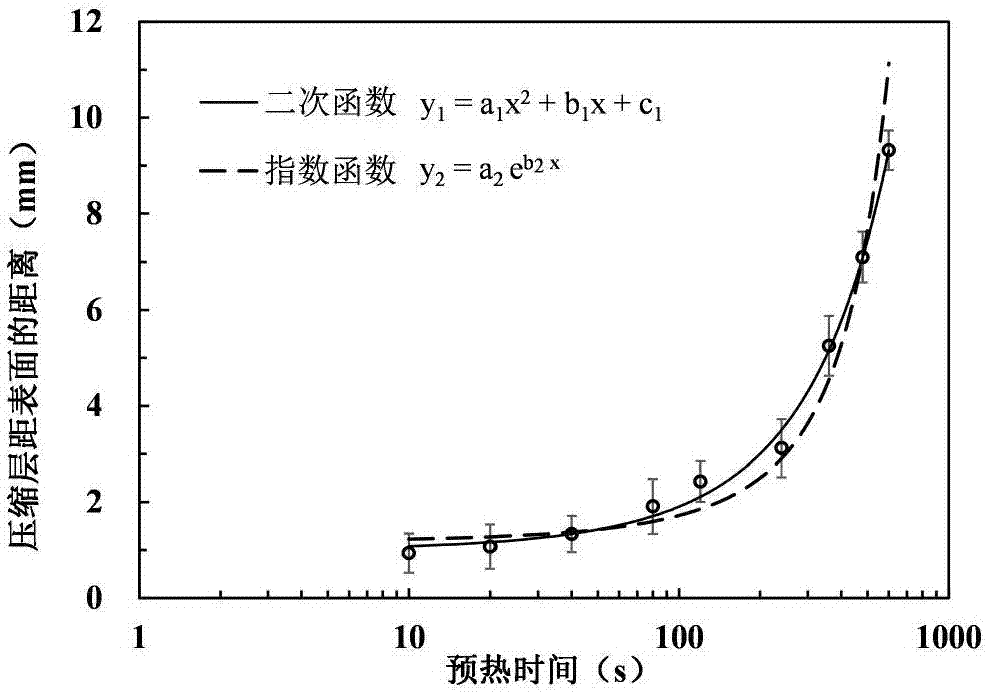

[0054] Embodiment 2: the fitting equation of compression layer position and preheating temperature and time is as shown in table 1,

[0055]

[0056] Table 1

[0057] The applicant conducts the test on wood with a thickness of 25mm, and the required compression amount is 5mm. During the preheating treatment, the test is divided into two groups, and the first group sets the preheating temperature as the variable x 1 (or x 2 ), the warm-up time is set to 720 seconds, according to y 1 =a 1 ln(x 1 )-c 1 The logarithmic function relationship of or The quadratic function relationship of the wood is controlled by adjusting the preheating temperature to control the position of the compression layer of the wood to achieve the selective directional densification of the wood; the second group sets the preheating time as the variable x 3 and x 4 , the preheating temperature is 180°C, according to The quadratic function relation of or The exponential function relationship of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com