Ore feeder

A technology for mining machine and car plate, which is applied in the direction of mining car, transport passenger car, railway car body parts, etc. Simple, break-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be further clearly and completely described below in conjunction with the embodiments and the accompanying drawings.

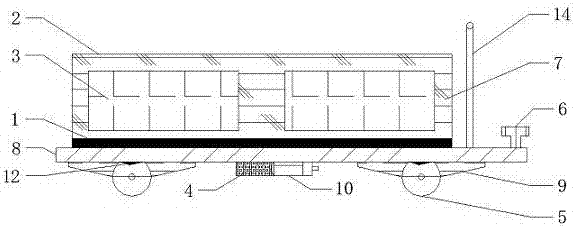

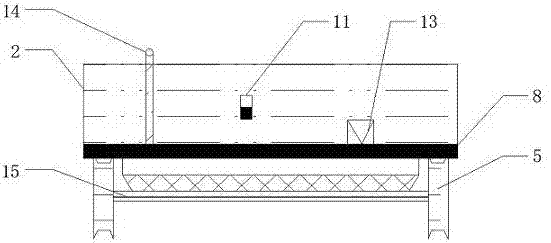

[0015] see figure 1 , figure 1 It is a structural schematic diagram of a feeder of the present invention. A mine feeder, including wheels 5, car boards 1 and support cabinets 7, a reinforcement plate 9 is fixedly installed above the wheels 5, the wheels 5 are used to move the mine feeder, and the wheels 5 are provided with concave edges , the inner concave edge is set to gradually increase from the inside to the outside, and the outer side of the wheel 5 is provided with an anti-rust and wear-resistant protective film, and the reinforcement plate 9 is used for shock absorption of the mine car, and the top of the reinforcement plate 9 is fixedly connected with The blade 12, the reinforcing plate 9 is provided with three layers, and the intersection of the three layers of reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com