Curved glass hot press and forming method

A technology of curved glass and hot press, which is applied in glass forming, glass reshaping, glass transportation equipment, etc. It can solve the problems of high preheating time, poor stability of curved glass forming, and insufficient temperature, etc., to achieve improved stability and uniformity, improve the sealing effect of protective gas, and reduce the effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] It should be noted that the following descriptions about front, back, left, right, up, down, X-axis, Y-axis, etc. are for the convenience of expression and understanding. They are defined or described according to the drawings and conventional understanding. They can be defined or described according to the viewing angle and placement. Different positions correspond to synchronous changes.

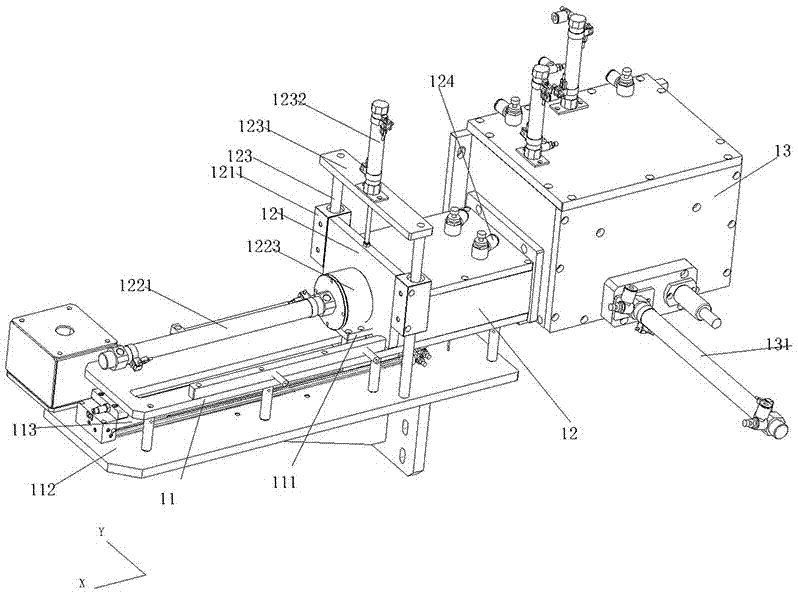

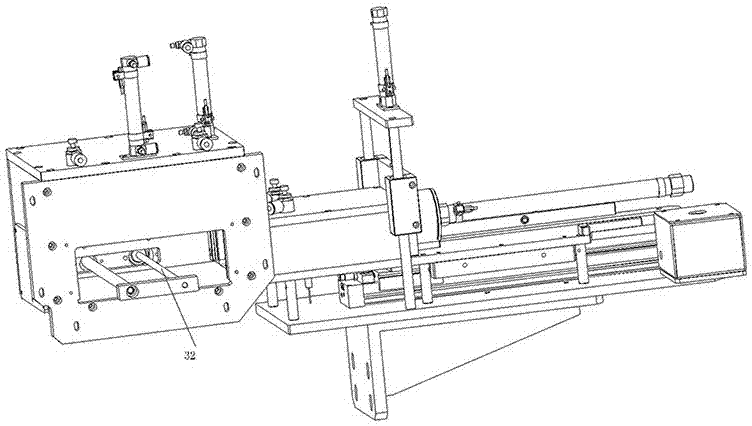

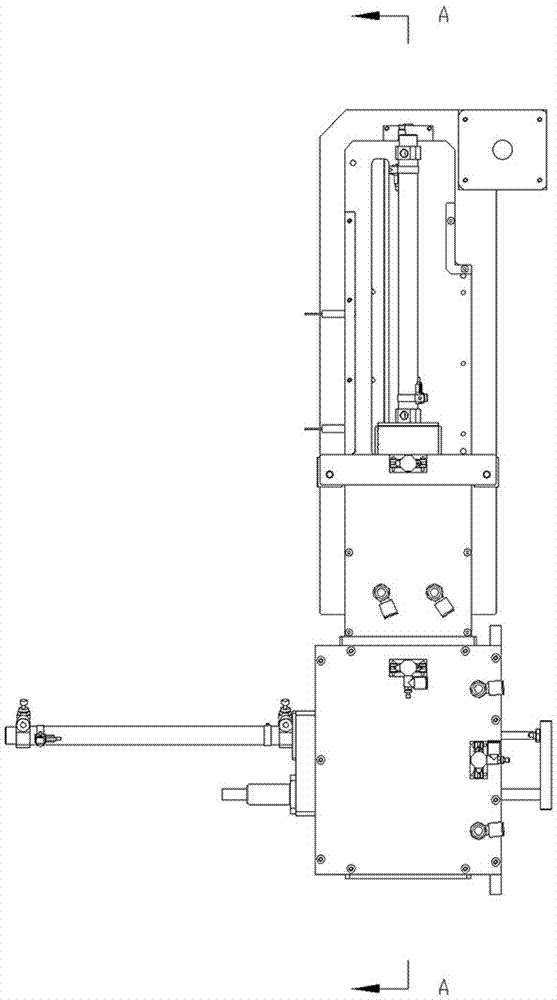

[0030] Such as Figures 1 to 5Shown is the structural solution of the feeding device 1 of the curved glass heat press in a certain preferred embodiment. The feeding device 1 can be applied to a curved glass hot press to automatically feed the graphite mold 8 . As shown in the figure, it includes a horizontal support plate 11 , a feed box 13 and a transition box 12 between the horizontal support plate 11 and the feed box 13 . Feeding box 13 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com