Installing structure of curtain wall plate

A technology for installing structures and curtain wall panels, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult to ensure connection strength, reduced installation efficiency, and difficult installation, to reduce the difficulty of installation operations, improve installation efficiency, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

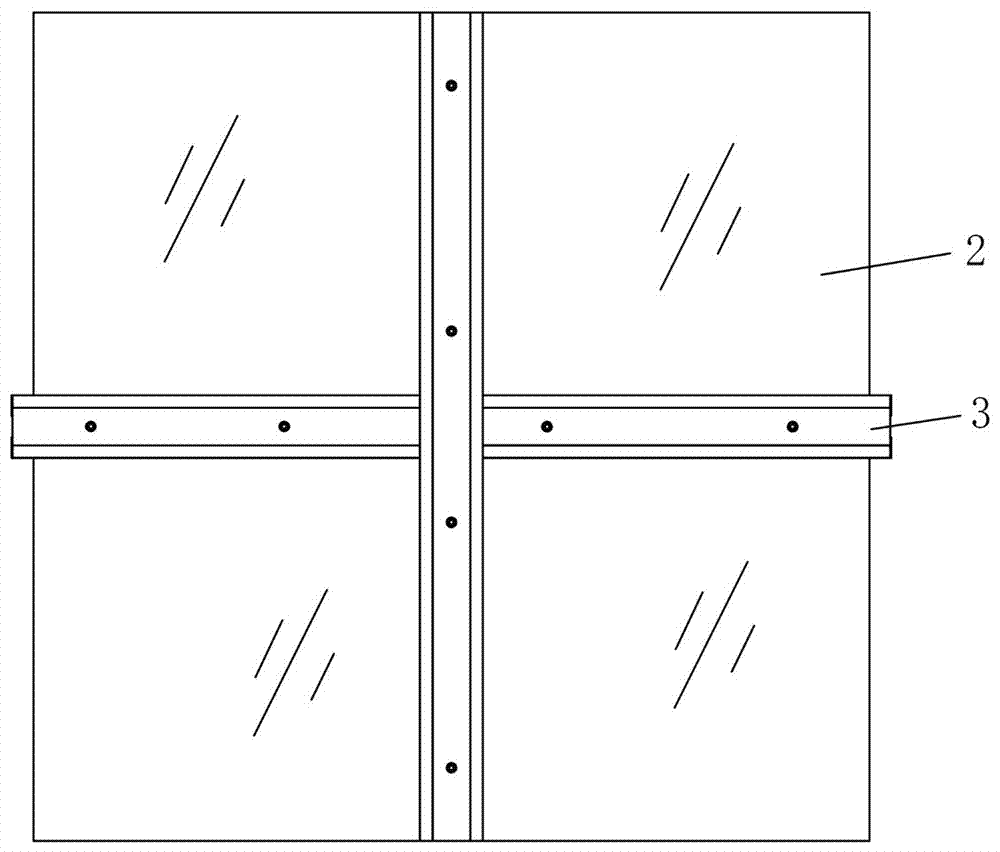

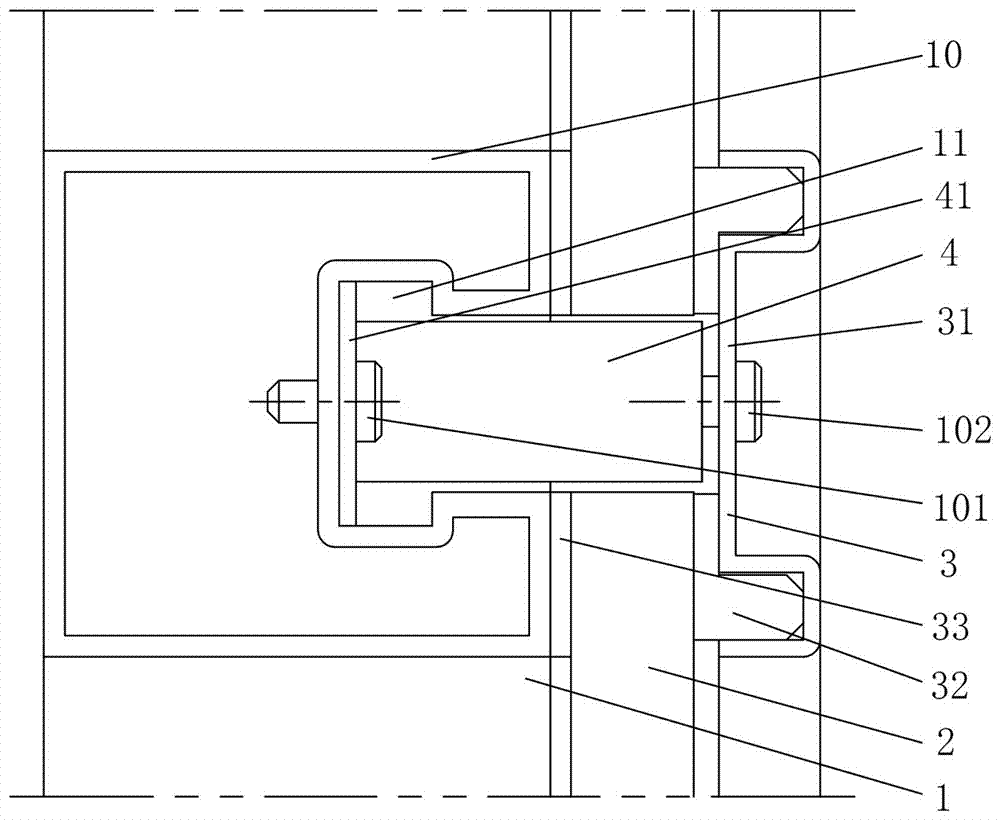

[0028] Such as Figure 1 to Figure 5 As shown, the installation structure of the curtain wall panel in this embodiment includes a keel frame 1, a curtain wall panel 2, and multiple sets of pressing components for pressing the curtain wall panel 2 on the keel frame 1. The keel 10 of the keel frame 1 is provided with an internal Expansion groove 11, the connecting assembly includes a pressing piece 3 for pressing the curtain wall panel 2 and more than one connecting piece 4 installed in the inner expanding groove 11, each connecting piece 4 is connected with the inner expanding concave through the first fastening assembly The inner wall of the groove 11 is fixedly connected, the pressing part 3 is connected with the connecting part 4 through a connecting mechanism, and each connecting part 4 has more than one limiting part 41 which prevents the connecting part 4 from coming out of the notch of the inner expansion groove 11.

[0029] In this embodiment, the first fastening compon...

Embodiment 2

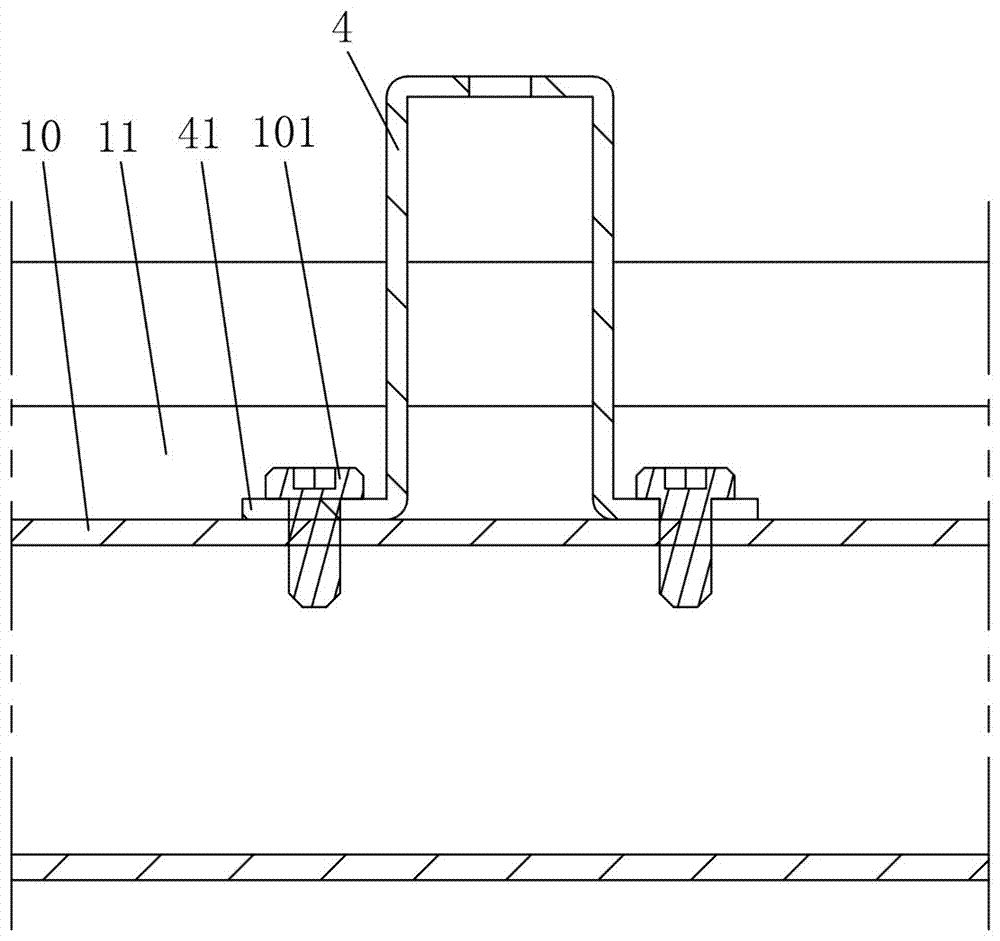

[0037] The curtain wall panel installation structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 6 to Figure 8 As shown, in this embodiment, the limiting part 41 is a sliding connection structure that only slides with the inner expansion groove 11, so that the inner expansion groove 11 limits all degrees of freedom of the connecting member 4 except sliding along the inner expansion groove 11 Even if the first fastening screw 101 becomes loose and fails, it will not escape from the inner expansion groove 11, and the connection with better stability can still be maintained through the cooperation of the limiting part 41 and the inner expansion groove 11.

[0038] In this embodiment, each inwardly expanding groove 11 is provided with an elastic portion 411 , and the elastic portion 411 elastically presses between the inner wall of the inwardly expanding groove 11 and the inwardly expanding groove 11 . After the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com