Non-destructive mining method

A mining method and tunnel technology, applied in the field of mining and non-destructive mining, can solve problems such as harm to the safety of mining workers, increase in accidents and disasters, and loss of unmined resources, so as to save labor and material costs, improve mining efficiency, and achieve non-destructive and efficient mining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

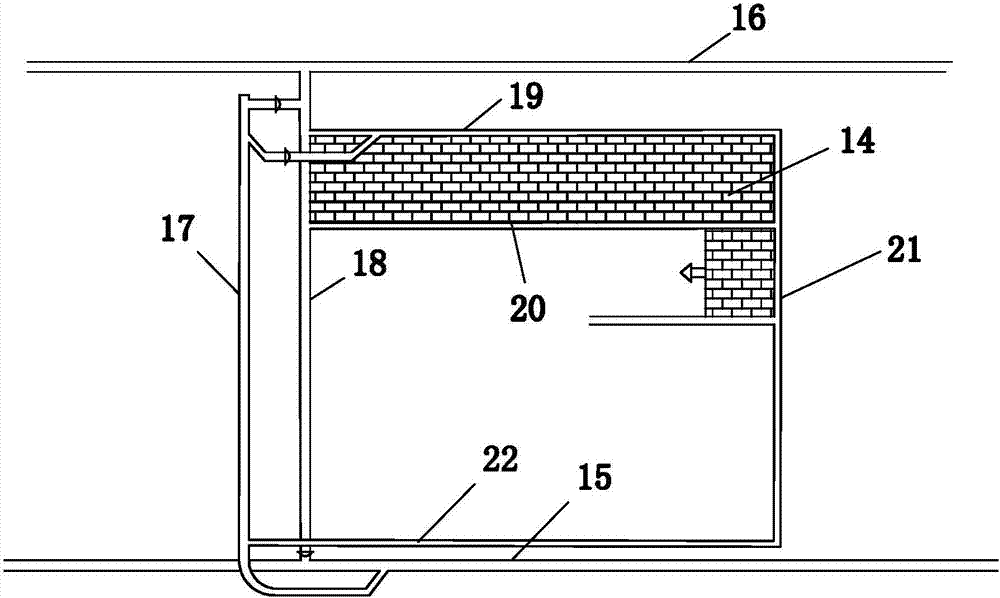

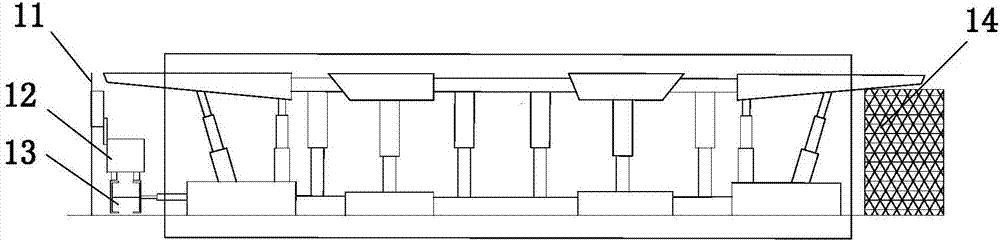

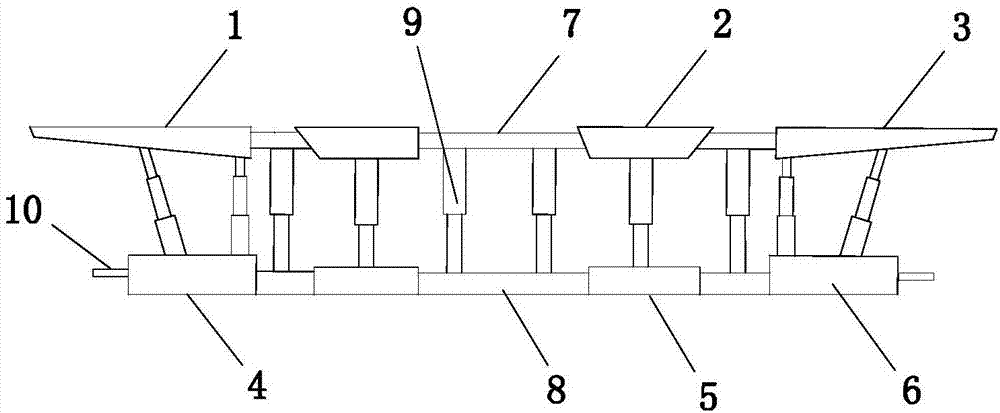

[0018] Such as Figure 1~4 As shown, the equipment used in the present invention is an independent composite hydraulic support for mining and charging. The hydraulic support includes a support beam, a support seat, a sliding support beam 7, and a sliding bottom beam 8. The support beam and the support seat pass through multiple vertical columns. Fixed connection; support beams include a front support beam 1, a rear support beam 3; one or more middle support beams 2 are arranged between the front support beam 1, and the rear support beam 3; adjacent support beams are supported by sliding The beams 7 are connected; the sliding support beam 7 can extend or contract along the horizontal direction.

[0019] The support seat includes a front support seat 4 and a rear support seat 6; one or more middle support seats 5 are arranged between the front support sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com