Rank learning-based quality evaluation method for deep scarification operation of farm machine

A quality evaluation, sorting and learning technology, applied in computer parts, data processing applications, instruments, etc., can solve the problem of not adopting an objective evaluation system for the quality of agricultural machinery subsoil operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

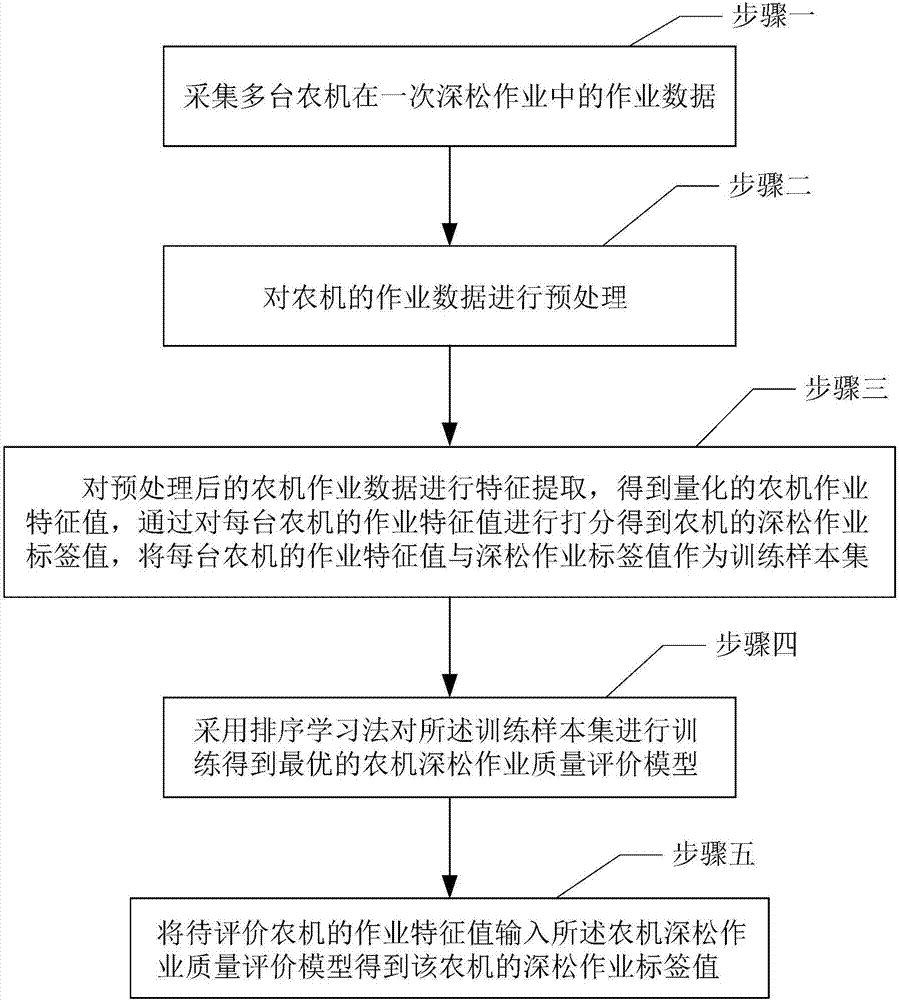

[0031] Embodiment one: combine below figure 1 This embodiment will be described in detail.

[0032] The method for evaluating the quality of subsoiling operations of agricultural machinery based on ranking learning described in this embodiment includes:

[0033] Step 1. Collect the operation data of multiple agricultural machines in one subsoiling operation;

[0034] The operation data of an agricultural machine includes multiple time nodes and the longitude, latitude, triaxial acceleration, triaxial angular velocity and cultivated land depth data of the deep plow of the agricultural machinery at each time node;

[0035] The time interval between two adjacent time nodes contained in the operation data of an agricultural machine is the same;

[0036] The time interval between two adjacent time nodes contained in the operation data of each agricultural machine is the same;

[0037] The three axes are X-axis, Y-axis and Z-axis respectively, the forward direction of the deep pl...

Embodiment 2

[0053] Embodiment 2: This embodiment further limits the method for evaluating the quality of subsoiling operations of agricultural machinery based on ranking learning described in Embodiment 1.

[0054] In the method for evaluating the quality of subsoiling operations of agricultural machinery based on ranking learning described in this embodiment, in step 2, the Gauss-Krüger projection method is used to convert the longitude and latitude coordinates under the geodetic coordinates into coordinates under the plane Cartesian coordinate system.

Embodiment 3

[0055]Embodiment 3: This embodiment further limits the method for evaluating the quality of subsoiling operations of agricultural machinery based on ranking learning described in Embodiment 1.

[0056] The method for evaluating the quality of subsoiling operations of agricultural machinery based on sorting learning described in this embodiment uses the dynamic time warping method to obtain the trajectory regularity of multiple plot trajectories of each agricultural machine. The specific process is: the plot trajectory and the plot The corresponding standard trajectory is normalized, and the dynamic time warping distance between the normalized plot trajectory and the normalized standard trajectory is taken as the trajectory regularity of the plot trajectory.

[0057] For trajectory A={a 1 ,a 2 ,...,a m} and trajectory B={b 1 ,b 2 ,...,b n}, in order to use the dynamic time warping method to nonlinearly align the two time series, it is necessary to construct an m×n cost mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com