Light full-sealed underwater automatic welding wire feeder

An automatic welding and wire feeding machine technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of equipment water seepage, high cost, heavy weight, etc., achieve stable operation and operation of equipment, reduce the probability of failure, Good effect of sealing and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

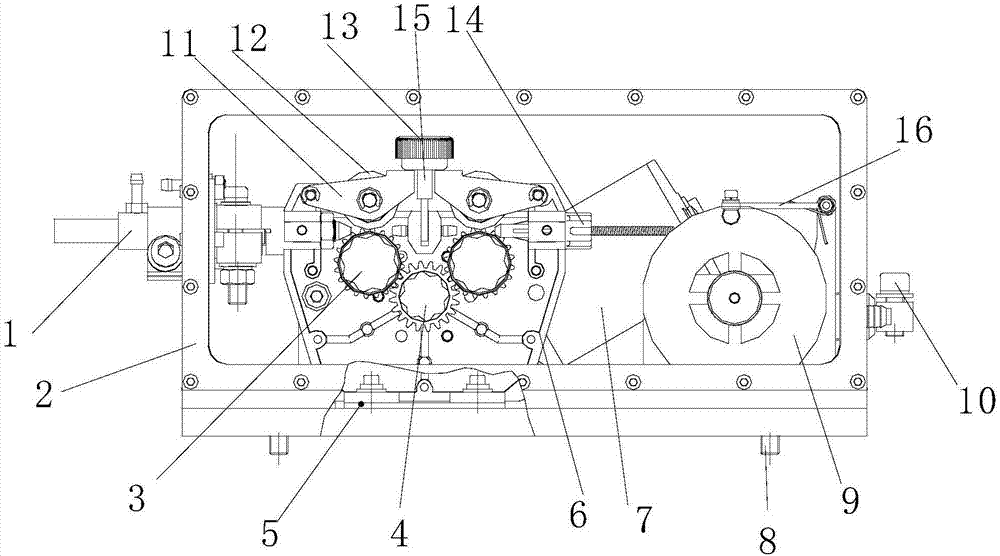

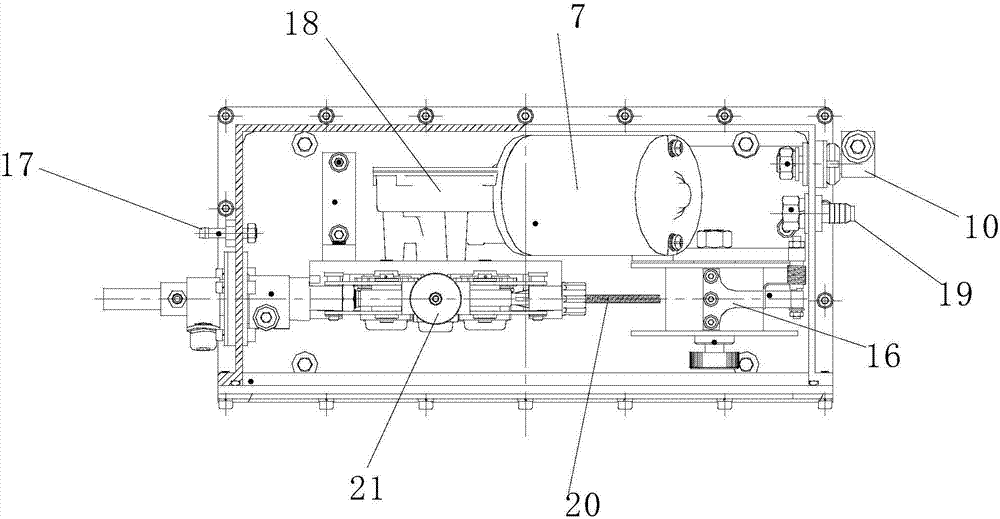

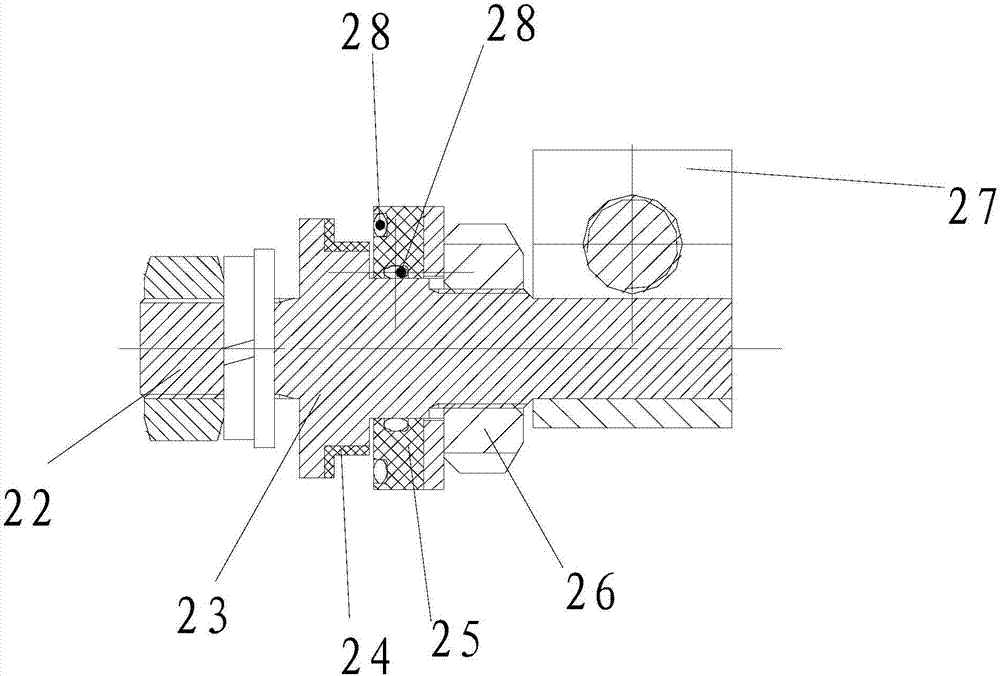

[0028] The present invention will be further described in detail below in conjunction with the drawings.

[0029] Lightweight and fully sealed underwater automatic welding wire feeder, including wire feed box, wire reel mechanism, reduction transmission mechanism, gear transmission mechanism, wire pressing mechanism, welding wire straightening mechanism, welding wire detection mechanism, welding wire reel mechanism, reduction transmission mechanism, The gear transmission mechanism, the wire pressing mechanism, the welding wire straightening mechanism, and the welding wire detection mechanism are all sealed in the wire feeding box, and the shielding gas filled into the wire feeding box through the air interface on the wire feeding box forms a box in the wire feeding box. The air pressure in the box with the external water pressure balanced, the sealed motor, the reduction transmission mechanism, and the gear transmission mechanism are connected in sequence. After the installation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com