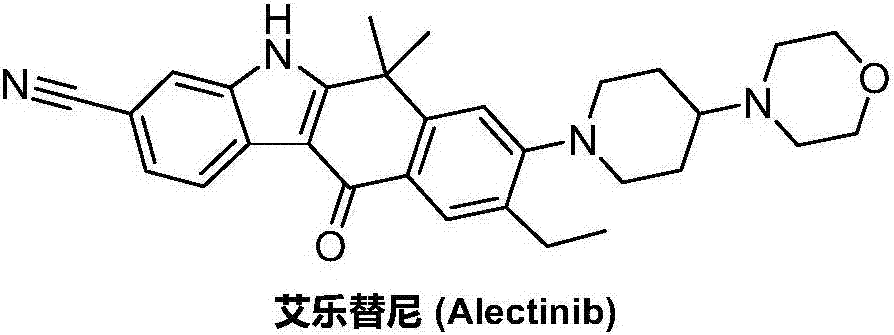

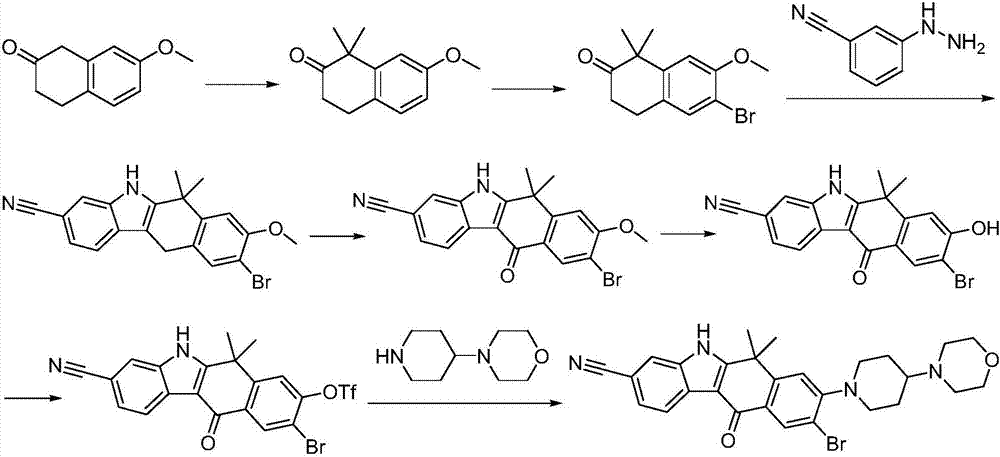

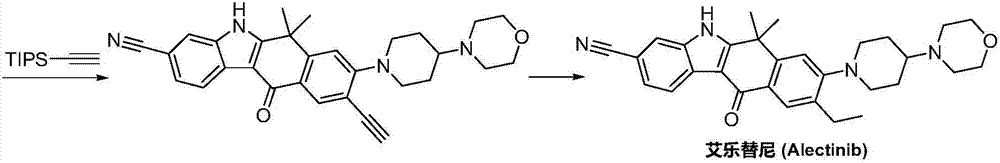

Method for preparing alectinib

A technology of alectinib and dihydrogen, which is applied in the field of pharmaceutical chemical synthesis, can solve the problems of unfavorable industrial production promotion, expensive starting materials, and the use of a large amount of solvents, and achieves easy and effective control of reaction conditions, reasonable and unique design, and reagents Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1

[0044] A) Preparation of 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone:

[0045] 6-Bromo-7-methoxy-3,4-dihydro-2-naphthone (6.0g, 23.5mmol) and a mass percentage concentration of 48% hydrobromic acid aqueous solution (39.6g, 234.9mmol) were added to the reaction flask, The reaction mixture was added to 100°C, refluxed and stirred for 24 hours. TLC spot plate confirmed the reaction was completed, the reaction solution was reduced to 0-5°C, 50% sodium hydroxide solution was slowly added to adjust the pH to 2, and the solution was precipitated at 0-5°C. Crystallize for 3h, filter, and recrystallize the filter cake with a mixed solvent of ethyl acetate and n-hexane to obtain 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone, an off-white solid (5.4g). The rate is 95%.

[0046] B) Preparation of 6-bromo-1,2,3,4-tetrahydro-2-oxo-7-naphthyl triflate:

[0047] 6-Bromo-7-hydroxy-3,4-dihydro-2-naphthone (5.0g, 20.7mmol) was dissolved in triethylamine (4.2g, 41.5mmol), and trifluorometh...

Example Embodiment

[0058] Example 2

[0059] A) Preparation of 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone:

[0060] 6-Bromo-7-methoxy-3,4-dihydro-2-naphthone (5.0g, 19.6mmol) and a mass percentage concentration of 48% hydrobromic acid aqueous solution (49.6g, 294.2mmol) were added to the reaction flask, The reaction mixture was added to 105°C, refluxed and stirred for 20 hours. TLC spot plate confirmed that the reaction was completed. The reaction solution was reduced to 0-5°C, and 50% sodium hydroxide solution was slowly added to adjust the pH to 2, and it was precipitated at 0-5°C. Crystallize for 3h, filter, and recrystallize the filter cake with a mixed solvent of ethyl acetate and n-hexane to obtain 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone, an off-white solid (4.7g). The rate is 99%.

[0061] B) Preparation of 6-bromo-1,2,3,4-tetrahydro-2-oxo-7-naphthyl triflate:

[0062] 6-Bromo-7-hydroxy-3,4-dihydro-2-naphthone (4.5g, 18.7mmol) was dissolved in N,N-diisopropylethylamine (6.0g, 46.4mmol), slowly...

Example Embodiment

[0073] Example 3

[0074] A) Preparation of 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone:

[0075] 6-Bromo-7-methoxy-3,4-dihydro-2-naphthone (2.5g, 9.8mmol) and a mass percentage concentration of 48% hydrobromic acid aqueous solution (8.3g, 49.2mmol) were added to the reaction flask, The reaction mixture was added to 95°C, stirred and reacted under reflux for 30 hours. TLC spot plate confirmed that the reaction was completed. The reaction solution was reduced to 0-5°C, and 50% sodium hydroxide solution was slowly added to adjust the pH to 2, and it was precipitated at 0-5°C. Crystallize for 3h, filter, and recrystallize the filter cake with a mixed solvent of ethyl acetate and n-hexane to obtain 6-bromo-7-hydroxy-3,4-dihydro-2-naphthone, an off-white solid (2.2g). The rate is 93%.

[0076] B) Preparation of 6-bromo-1,2,3,4-tetrahydro-2-oxo-7-naphthyl triflate:

[0077] 6-Bromo-7-hydroxy-3,4-dihydro-2-naphthone (2.2g, 9.1mmol) was dissolved in pyridine (1.1g, 13.9mmol), and trifluoromet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com