A fluidized reaction device and fluidized reaction method for coating anti-sticking agent to inhibit iron ore powder from cohesive loss

A technology of fluidization reaction and anti-adhesion agent, applied in the direction of fluidized bed furnace, furnace type, furnace, etc., can solve the problem of difficulty in effectively suppressing the loss of iron ore powder adhesion, so as to inhibit the loss of adhesion and accelerate the cooling process. , the effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

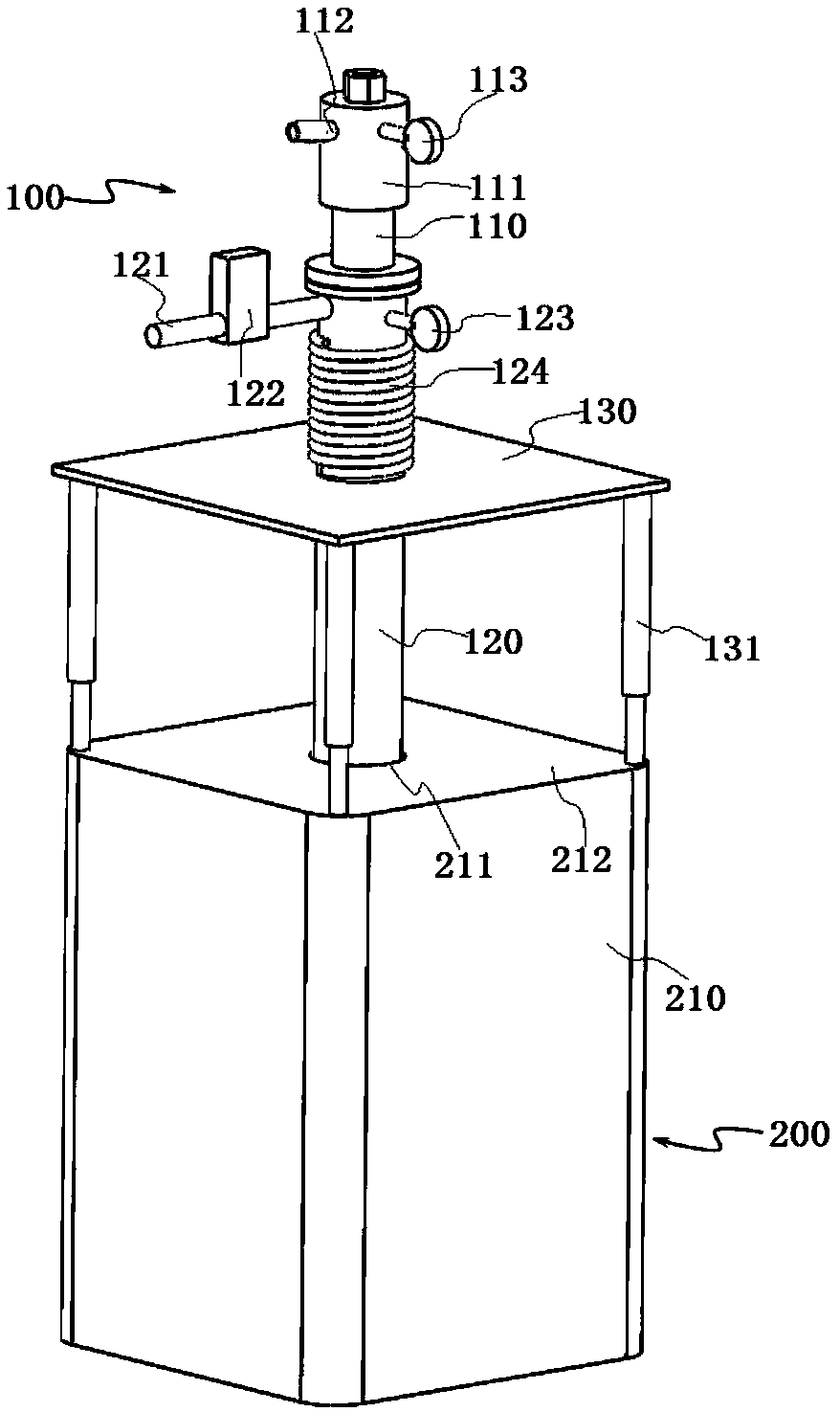

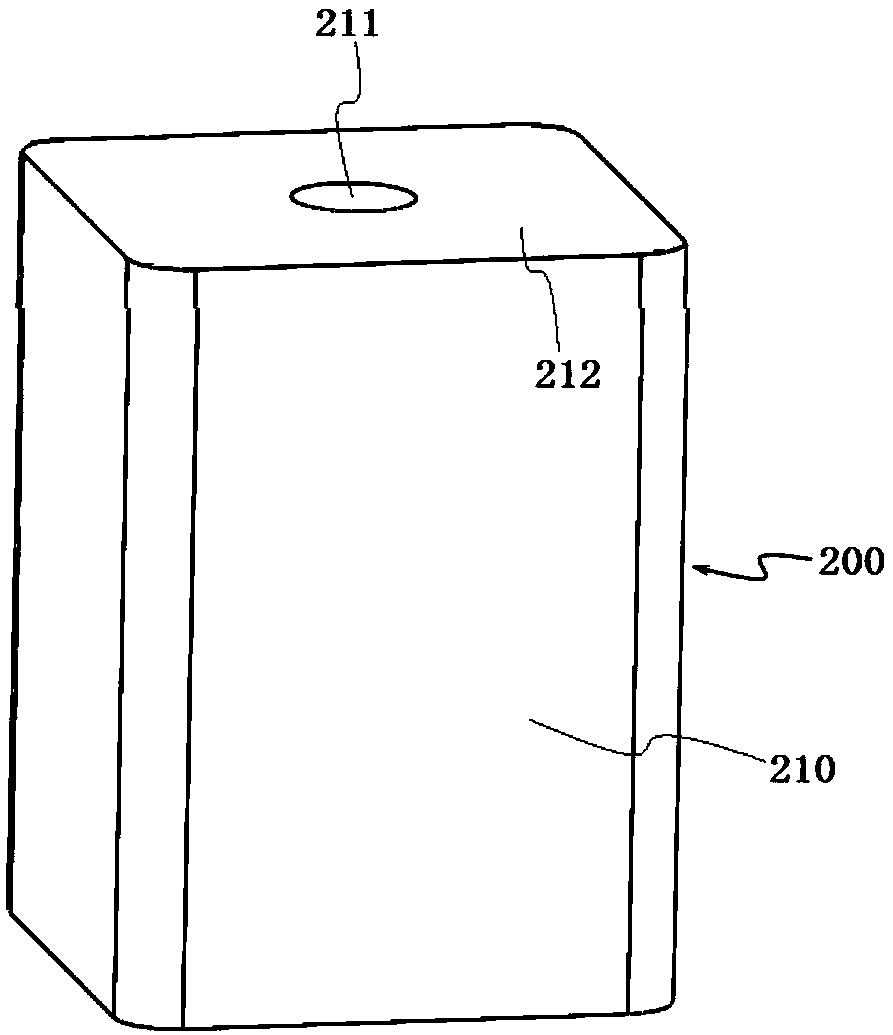

[0042] combine figure 1 , figure 2 and Figure 5 , a fluidized reaction device coated with an anti-adhesive agent of the present invention to inhibit the cohesion and loss of iron ore powder, including a double-layer tube reaction unit 100, a heating unit 200 and a material mixing unit 300; Figure 5 As shown, the material mixing unit 300 is used to mix the iron ore powder and the anti-sticking agent, and the mixed iron ore powder and the anti-sticking agent are added to the double-layer tube reaction unit 100; the material mixing unit 300 includes a mixing tank 310 and agitator 320, iron ore powder and anti-sticking agent are added into the mixing tank 310, and the agitator 320 is turned on for mixing.

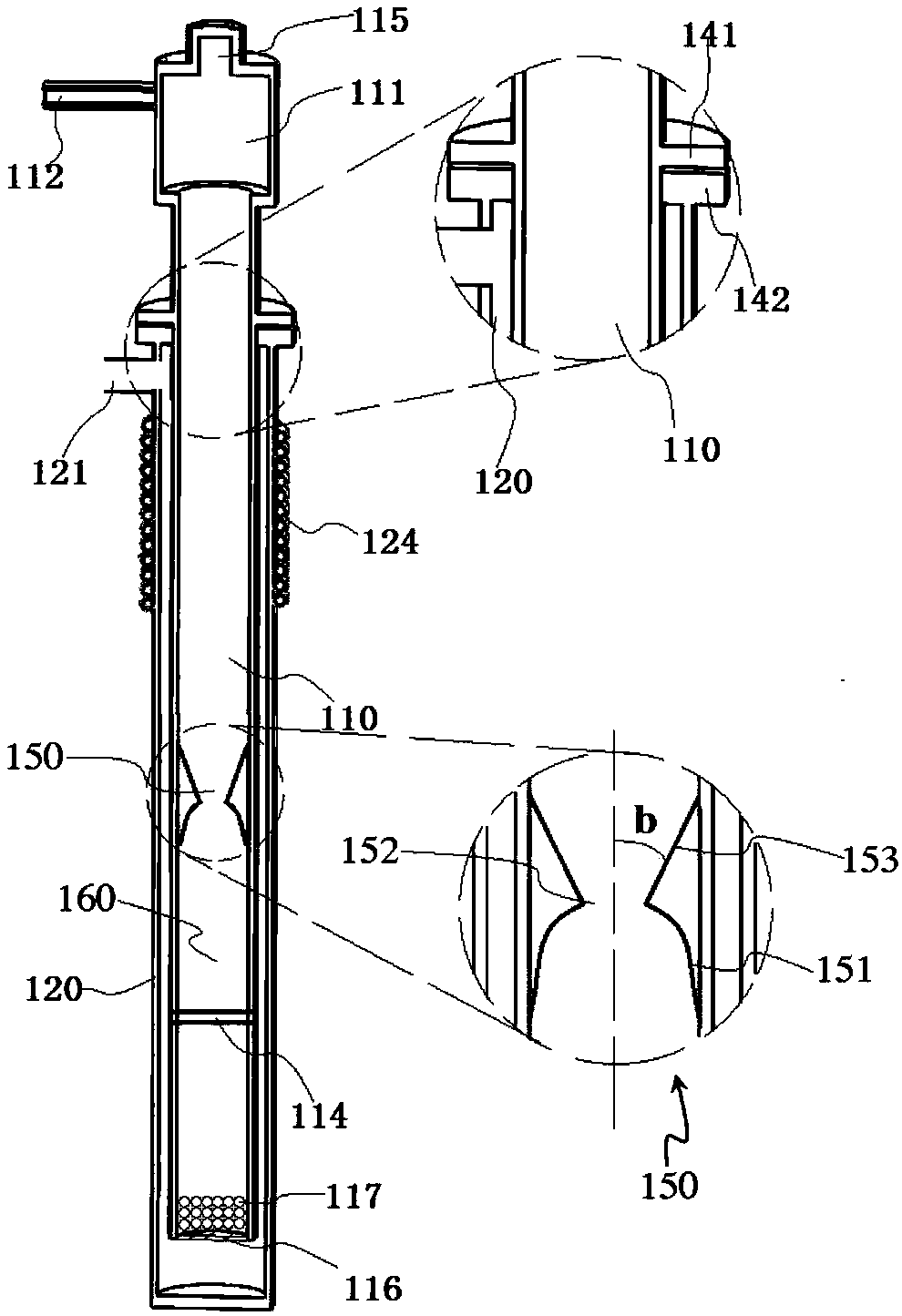

[0043] The double-tube reaction unit 100 of the present embodiment includes a reaction inner tube 110, an outer sleeve 120 and a support platform 130, the middle part of the support platform 130 is provided with a through hole matched with the outer sleeve 120, and the out...

Embodiment 2

[0052] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: the bottom of the reaction inner tube 110 is provided with a mesh-like support grate plate 116, and ceramic balls 117 are laid on the support grate plate 116. The ceramic balls 117 is set to 3-5 layers (such as image 3 As shown), preferably three layers, after the gas flows through the multilayer ceramic balls 117, the ceramic balls 117 can make the gas flow evenly distributed in the reaction inner tube 110.

[0053] Such as Figure 6 and Figure 7As shown, the fluidized bed sieve plate 114 includes outer edge air holes 1141, middle air holes 1142, inner edge air holes 1143 and central air holes 1144; inner edge air holes 1143, middle air holes 1142 and outer edge air holes 1141 are arrayed in the center sequentially from inside to outside Outside the air hole 1144; the aperture of the outer edge air hole 1141 is larger than the aperture of the inner edge air hole 11...

Embodiment 3

[0055] The basic content of this embodiment is the same as that of Embodiment 1, the difference being that a transparent observation port 1151 is arranged on the top of the feeding port 115, and the fluidized reduction process of the iron ore powder in the reaction inner tube 110 can be observed through the observation port 1151, thereby improving Visually and accurately study the fluidized reduction process of iron ore powder (such as Figure 4 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com