Worm and gear traction system for bridge rotating body, and traction method

A worm gear, traction system technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of insufficient hydraulic and artificial traction power stability, poor traction stability effect, large working space, etc. Application and promotion value, avoid traction lag effect, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

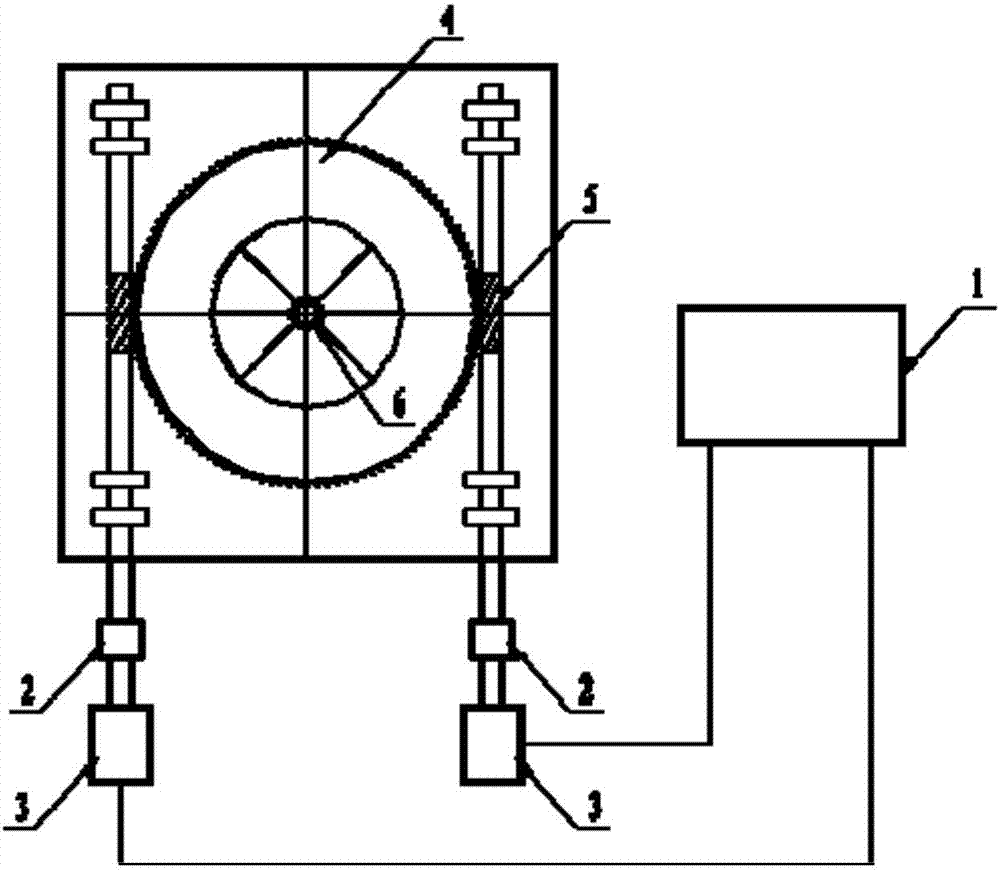

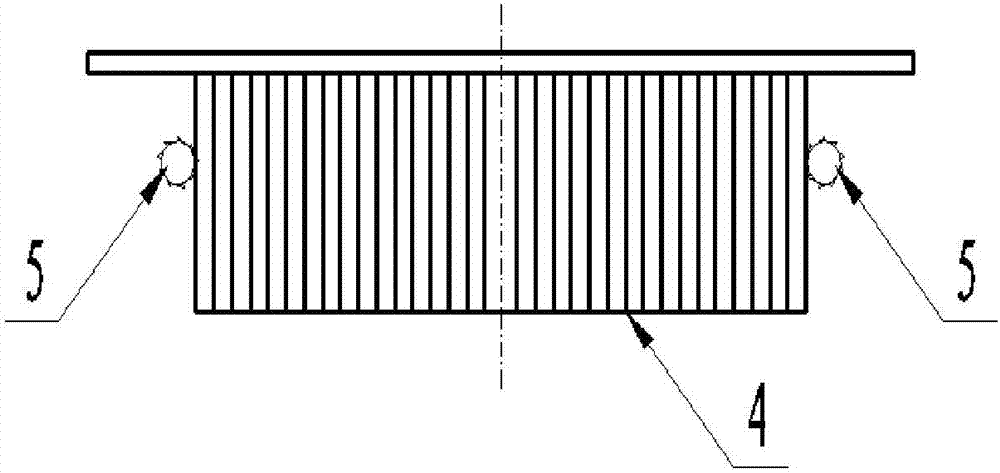

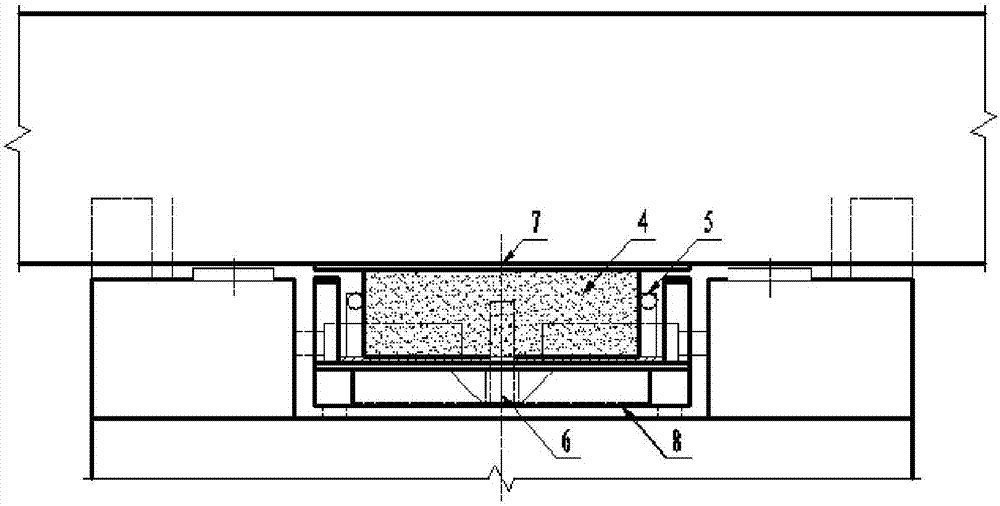

[0020] Such as Figure 1 to Figure 4 As shown, a worm gear traction system of a bridge swivel mainly includes a control system 1, a power system 3, a reduction device 2, a worm wheel 4, a worm 5, an upper turntable 7 and a lower turntable 8, and the control system 1 and the power system 3 circuit connection, the control system 1 is set independently, the power system 3 is set independently or on the lower turntable 8, the power system 3 is connected to the deceleration device 2, the deceleration device 2 is mechanically connected to the worm 4, and the worm gear 4 cooperates with the worm 5 connected, and the worm 5 is two parallel and symmetrically installed on both sides of the worm wheel 4, the hub of the worm wheel 4 is inlaid with the outer ring of the upper turntable 7, and the upper turntable 7 is connected with the lower turntable 8 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com