Overall assembly type frame structure house

A frame structure and assembled technology, which is applied in the direction of building structure and construction, can solve the problems of heavy on-site assembly workload, difficulty in ensuring the overall quality, and low production efficiency, so as to improve labor productivity, easy to ensure the overall quality, and improve production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

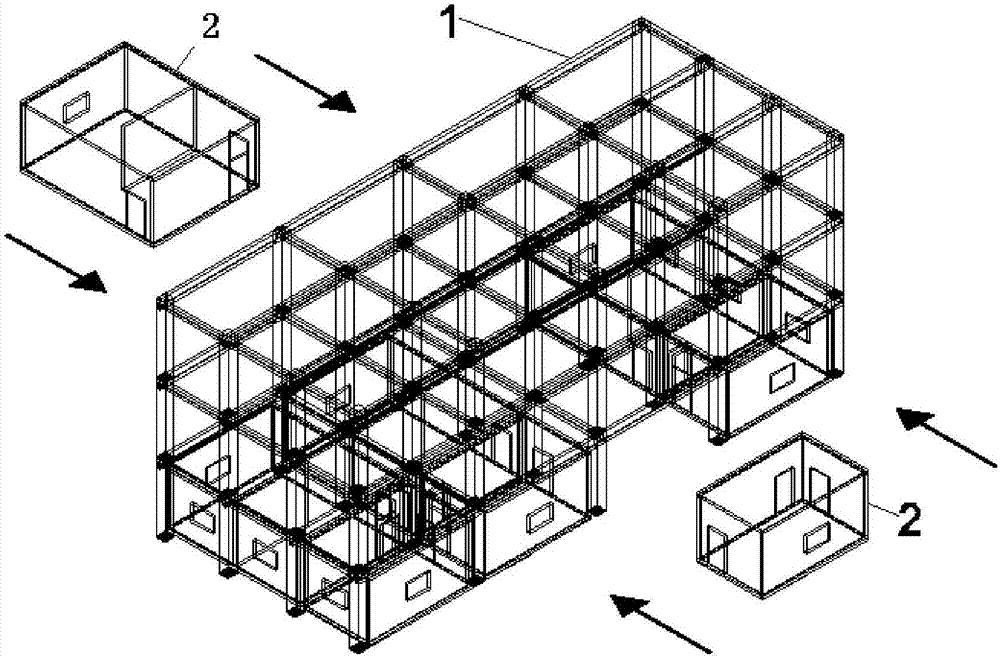

[0018] Such as figure 1 As shown, the overall assembled frame structure house of the present invention includes a house frame 1 and a plurality of standard board houses 2, each space of the house frame 1 can accommodate at least one standard board house 2, and the standard board house 2 is a whole forming.

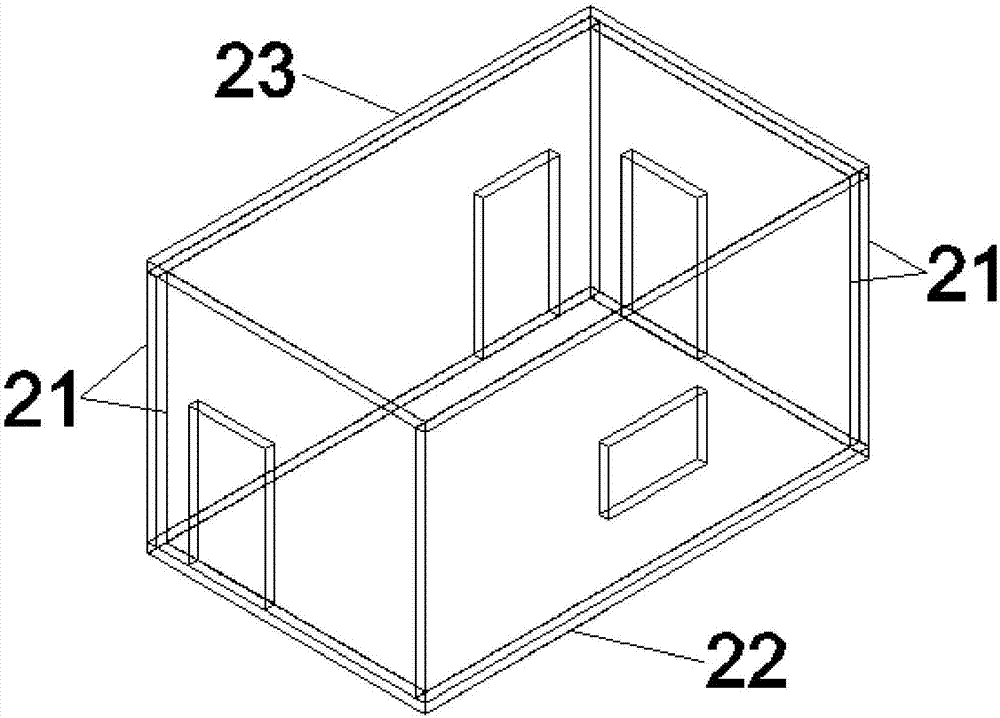

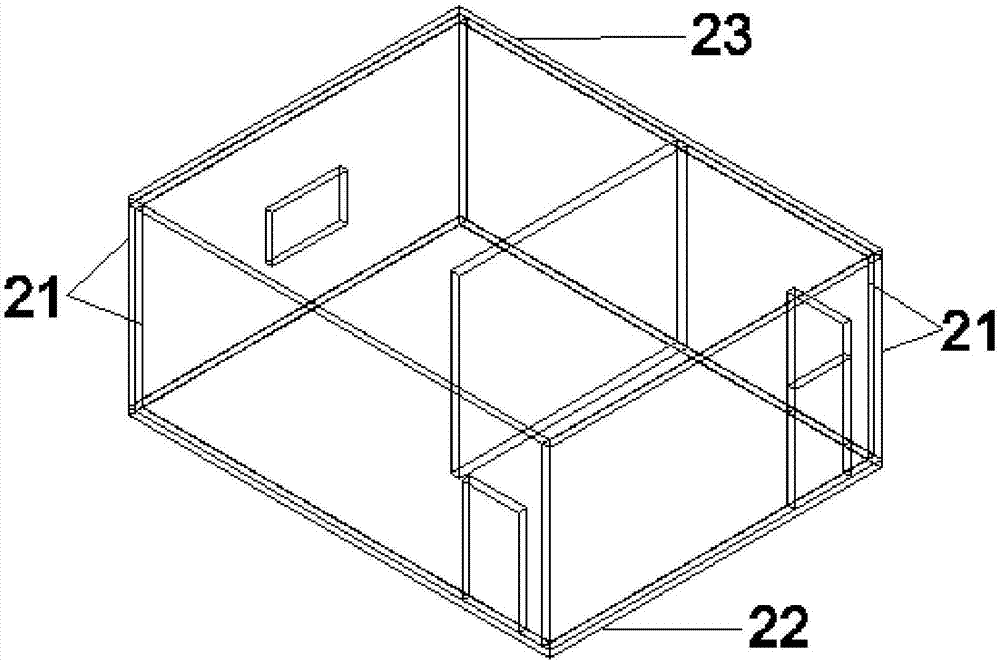

[0019] Such as figure 2 , 3 As shown, the standard prefabricated house 2 includes four walls 21 , a ground 22 and a top 23 , and the walls 21 are integrally cast with the ground 22 and the top 23 .

[0020] The wall 21 is provided with doors and windows as required.

[0021] image 3 The standard prefabricated house 2 is also provided with a partition inside to further separate the inside. figure 2 There is no further separation.

[0022] The standard board house 2 is riveted with the house frame 1 on site.

[0023] The house frame 1 can be a steel structure frame or a cast-in-place concrete frame.

[0024] The standard board house 2 is assembled into a whole by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com