A dual-circuit scale-free steam generation structure

A dual-circuit and scale technology is applied in the field of double-circuit scale-free steam generation structure, which can solve the problems of high water source cost and unfavorable general application, and achieve the effect of solving the problem of easy generation of scale, easy maintenance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

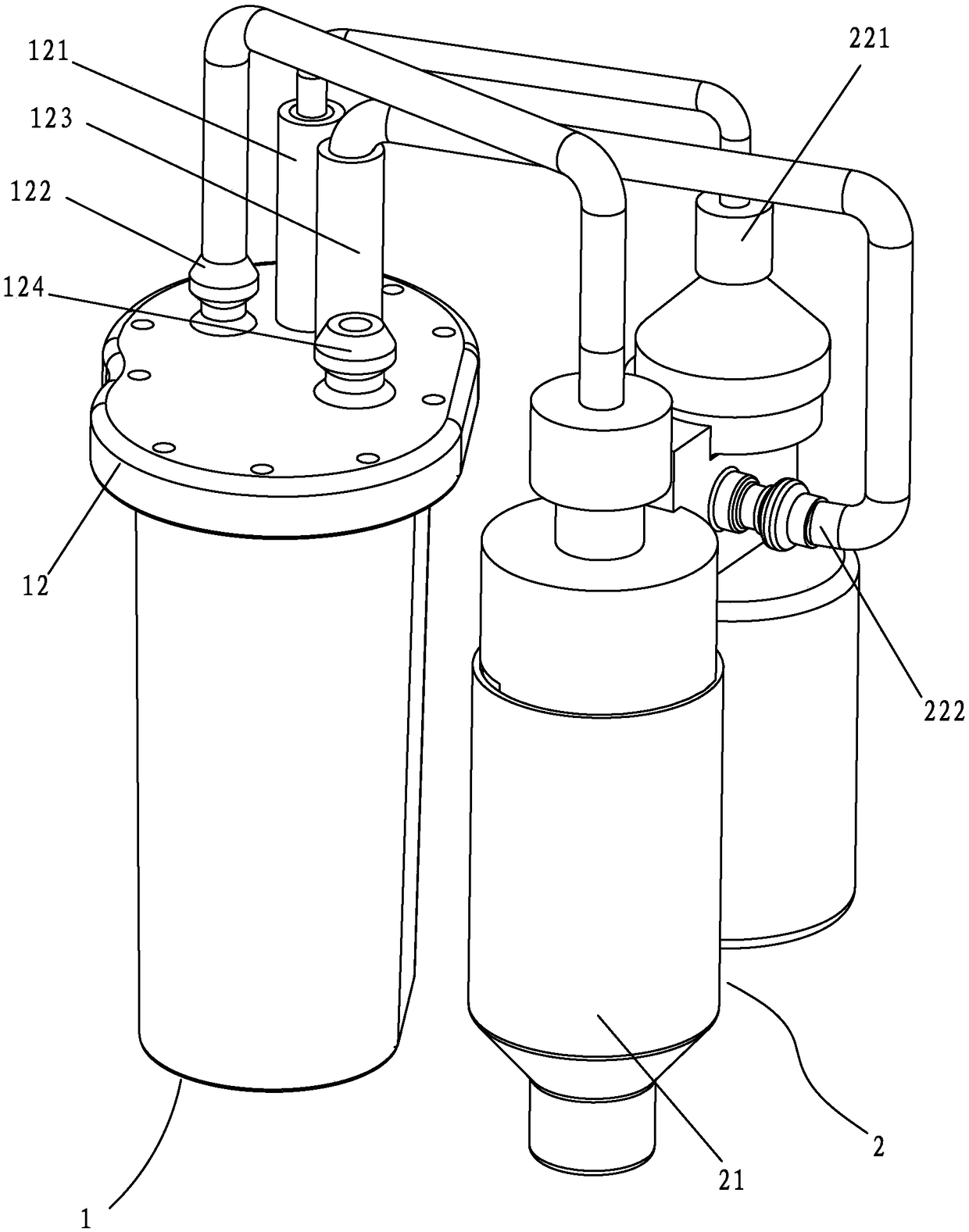

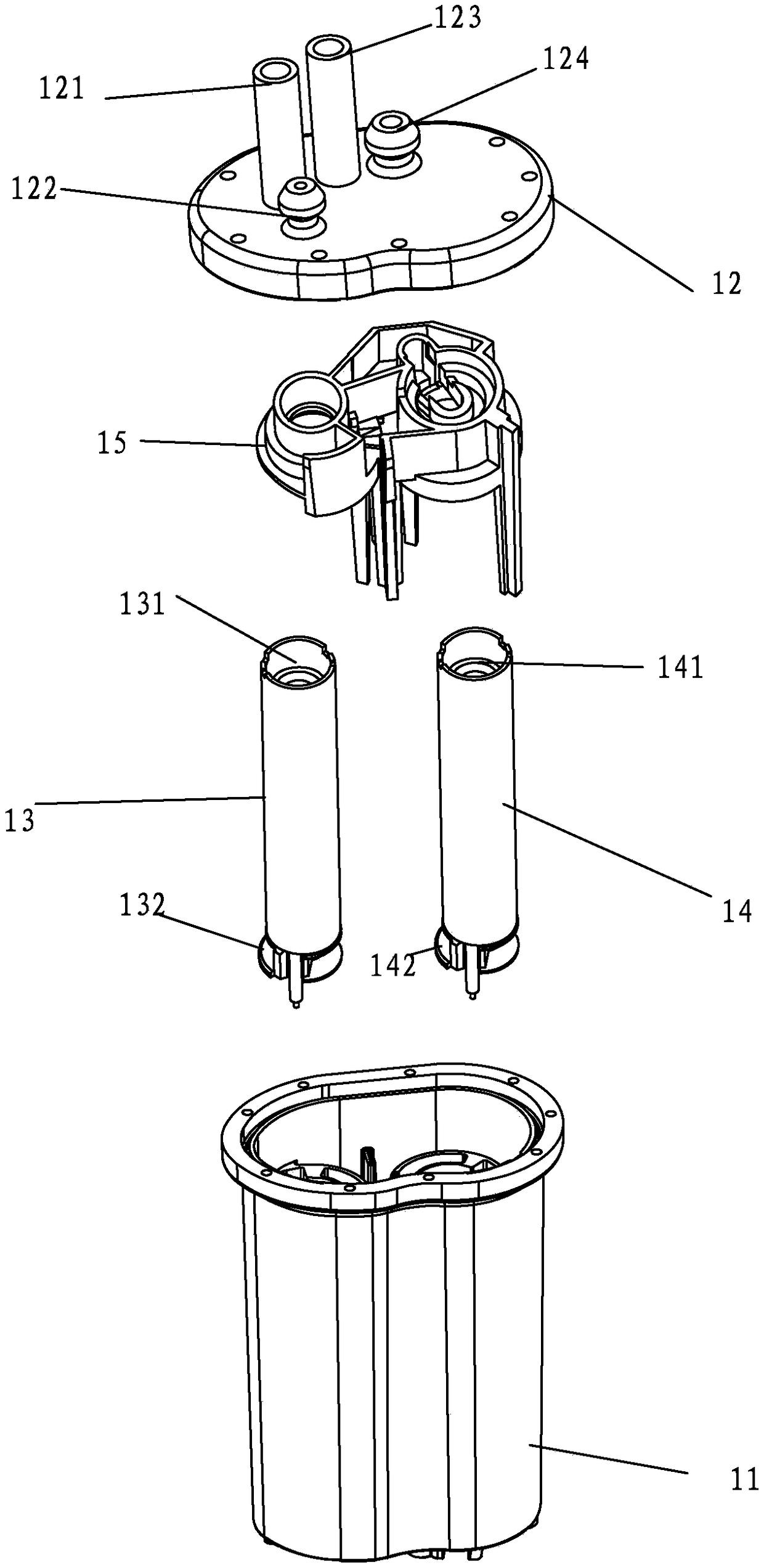

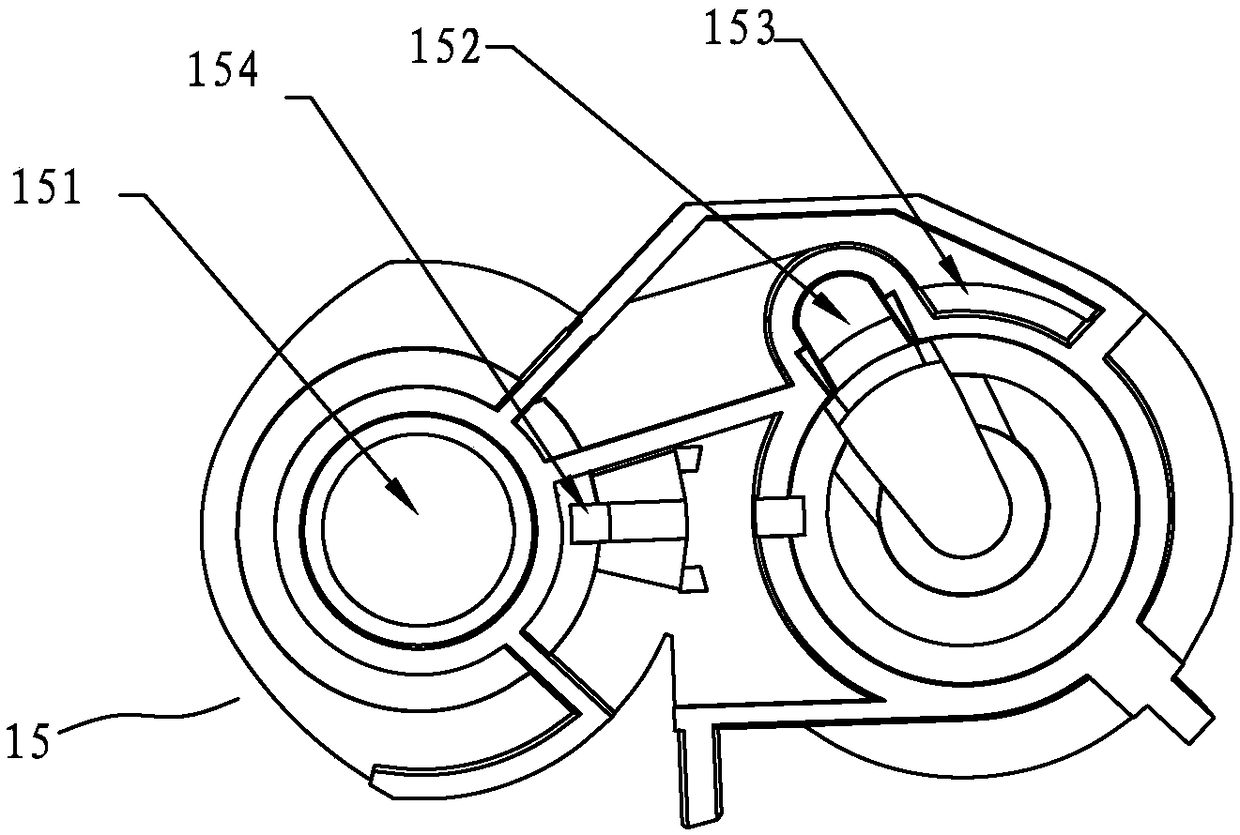

[0032] Such as Figure 1 to Figure 8 As shown, a dual-circuit non-scale steam generating structure includes:

[0033] The integrated heating device 1 includes a housing 11 and a sealing cover 12 connected to the opening of the housing 11. The housing 11 is provided with an airflow heating device 13 and a dry steam heating device 14; the airflow heating device 13 is provided with an inlet The air inlet 131 and the air outlet 132, the dry steam heating device 14 is provided with a steam inlet 142 and a steam outlet 141. The present invention places both the air flow heating device and the dry steam heating device in an integrated heating device with a simple and compact structure. The overall volume is reduced, which is conducive to energy saving.

[0034] The sealing cover 12 is provided with an air inlet 121, an air outlet 122, a steam inlet 123, and a steam outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com