Roller tea dryer using electric heating device with air guide cover

An electric heating device, tea dryer technology, applied in dryers, tea drying, non-progressive dryers, etc., can solve the problems of high energy consumption, waste of thermal energy, low thermal efficiency, etc., to save electric energy, use Easy to operate and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

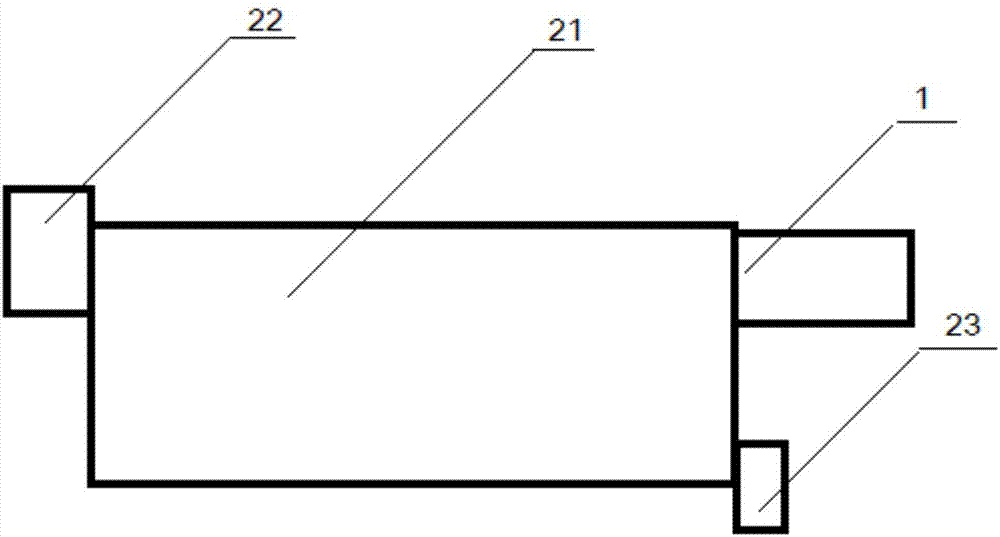

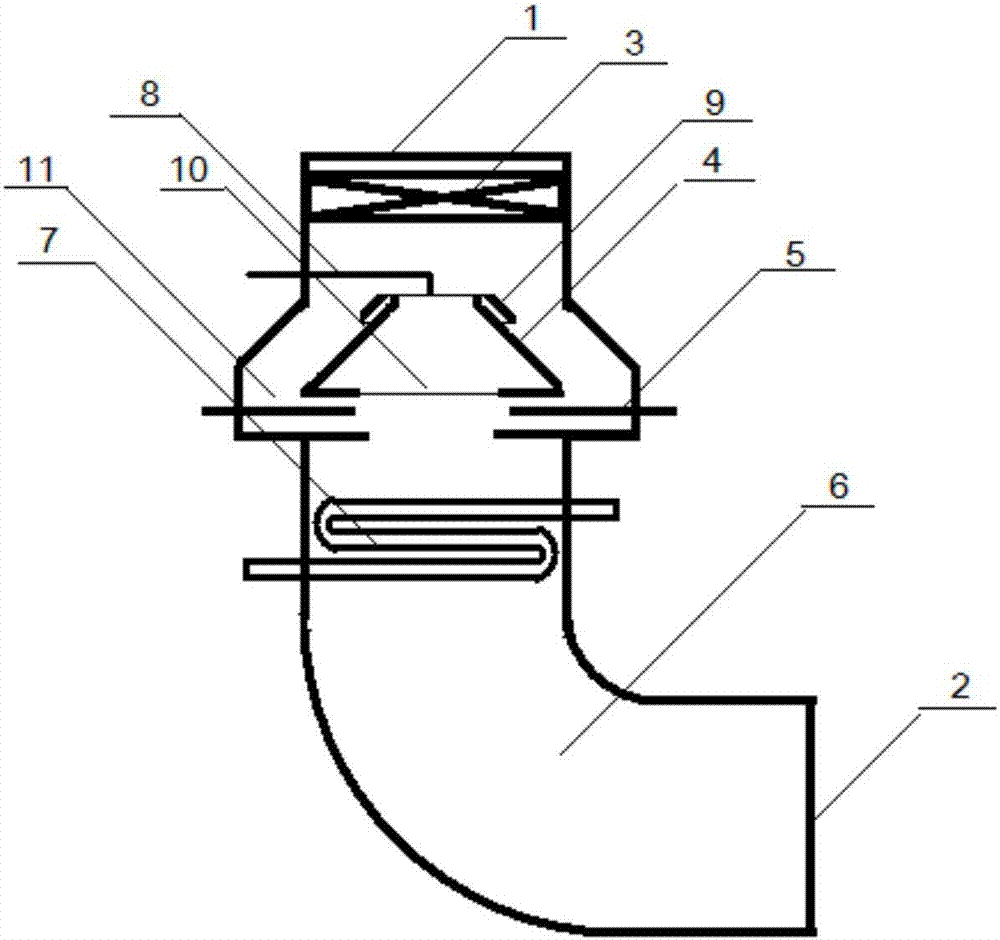

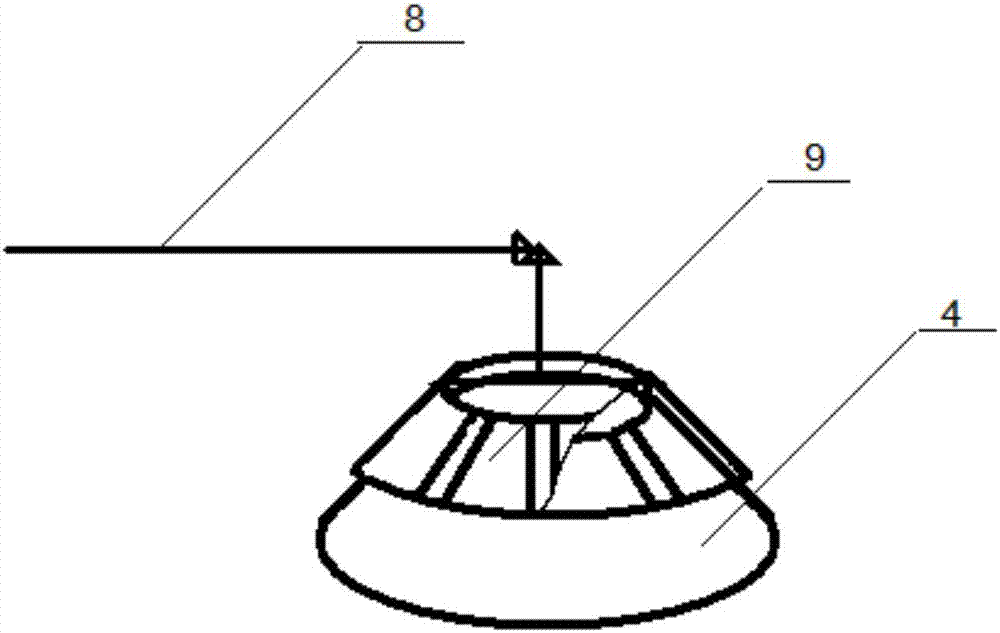

[0021] Embodiment 1: A drum-type tea dryer using an electric heating device with an air guide cover. The upper left end of the drum 21 for drying tea is provided with a feed port 22 for adding tea leaves, and the lower right end of the drum 21 is provided with a tea discharge outlet. The discharge port 23 of the discharge port 23 is provided with an electric heating device with an air guide cover for supplying heated air to the drum 21; , an electric fan 3, a shroud 4 and an electric heater 5, an electric fan 3 blowing inward is provided at the air inlet 1, and a shroud 4 for shunting the cold air is arranged under the fan 3, and the shroud 4 divides the cold air into The cold air channel 10 directly passing through without heating and the heated hot air channel 11 are two parts. The hot air channel 11 is provided with an electric heater 5 for heating, and the lower part of the electric heater 5 is provided with an air guide tube 6. The heated hot air is mixed in the air guide...

Embodiment 2

[0022] Embodiment 2: A drum-type tea dryer using an electric heating device with an air guide hood. The upper left end of the drum 21 for drying tea is provided with a feed port 22 for adding tea leaves, and the lower right end of the drum 21 is provided with a tea discharge outlet. The discharge port 23 of the discharge port 23 is provided with an electric heating device with an air guide cover for supplying heated air to the drum 21; , an electric fan 3, a shroud 4 and an electric heater 5, an electric fan 3 blowing inward is provided at the air inlet 1, and a shroud 4 for shunting the cold air is arranged under the fan 3, and the shroud 4 divides the cold air into The cold air channel 10 directly passing through without heating and the heated hot air channel 11 are two parts. The hot air channel 11 is provided with an electric heater 5 for heating, and the lower part of the electric heater 5 is provided with an air guide tube 6. The heated hot air is mixed in the air guide ...

Embodiment 3

[0023] Embodiment 3: A drum-type tea dryer using an electric heating device with an air guide hood, the upper left end of the drum 21 for drying tea is provided with a feed port 22 for adding tea leaves, and the lower right end of the drum 21 is provided with a tea discharge outlet The discharge port 23 of the discharge port 23 is provided with an electric heating device with an air guide cover for supplying heated air to the drum 21; , an electric fan 3, a shroud 4 and an electric heater 5, an electric fan 3 blowing inward is provided at the air inlet 1, and a shroud 4 for shunting the cold air is arranged under the fan 3, and the shroud 4 divides the cold air into The cold air channel 10 directly passing through without heating and the heated hot air channel 11 are two parts. The hot air channel 11 is provided with an electric heater 5 for heating, and the lower part of the electric heater 5 is provided with an air guide tube 6. The heated hot air is mixed in the air guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com