GMI sensor probe based on ring-shaped amorphous wire and preparation method thereof

A sensor probe, amorphous wire technology, applied in the size/direction of the magnetic field, instruments, magnetic field measurement using electromagnetic devices, etc., can solve the problems of limited spatial resolution of amorphous wire, limited, etc. Avoid the effect of shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

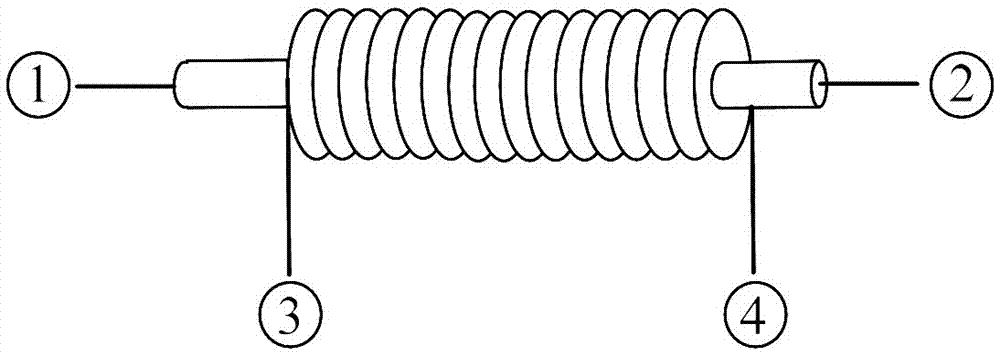

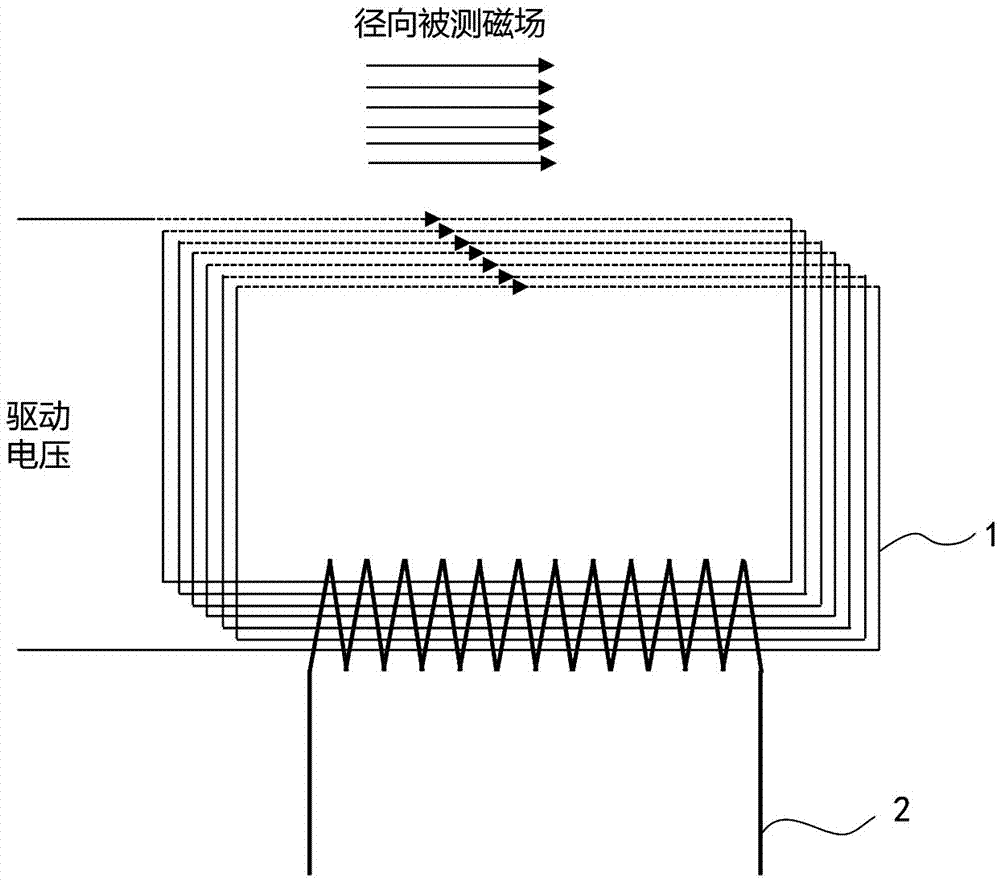

[0013] Such as figure 2 As shown, the GMI sensor probe based on the loop-shaped amorphous wire of this embodiment includes an amorphous wire coil 1 wound in a loop, and the amorphous wire coil 1 includes a magnetic field-sensitive amorphous wire segment ( figure 2 Indicated by the dotted line in the middle) and the loss of magnetic field sensitive amorphous wire segment ( figure 2 Indicated by a solid line in the middle), a signal pickup coil 2 is wound on the section of the amorphous wire sensitive to loss of magnetic field. The GMI sensor probe based on the ring-shaped amorphous wire of this embodiment can overcome the processing shortcomings of the amorphous wire itself, which is difficult to weld. While realizing the spatial reuse of the amorphous wire, it only needs to use the mature heat treatment process in the material process instead of performing A large number of complex and immature amorphous wire welding; and the GMI sensor probe based on the loop-shaped amorph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com