Method for counting silicon wafers based on machine vision and image processing

An image processing and machine vision technology, applied in the field of image processing, can solve problems such as easy operation, unsatisfactory image quality of cell slices, affecting counting accuracy, etc., and achieve the effect of improving counting accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

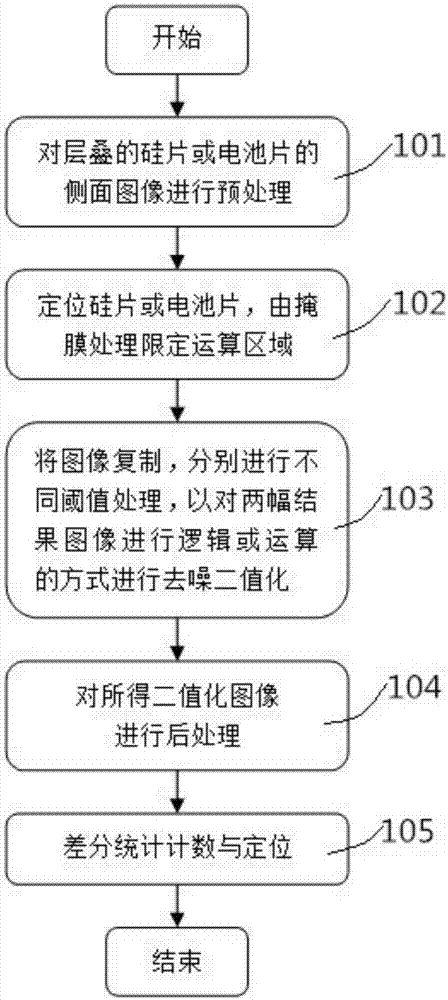

[0065] Such as figure 1 Shown, the method for counting solar silicon wafers and cells based on image processing comprises the following steps:

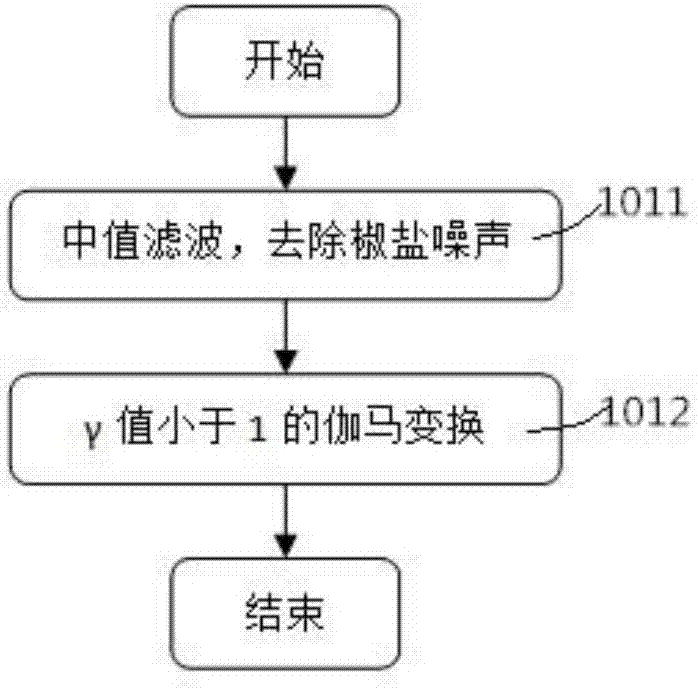

[0066] Step 101, preprocessing the side image of the stacked silicon wafer or battery sheet, such as figure 2 Shown:

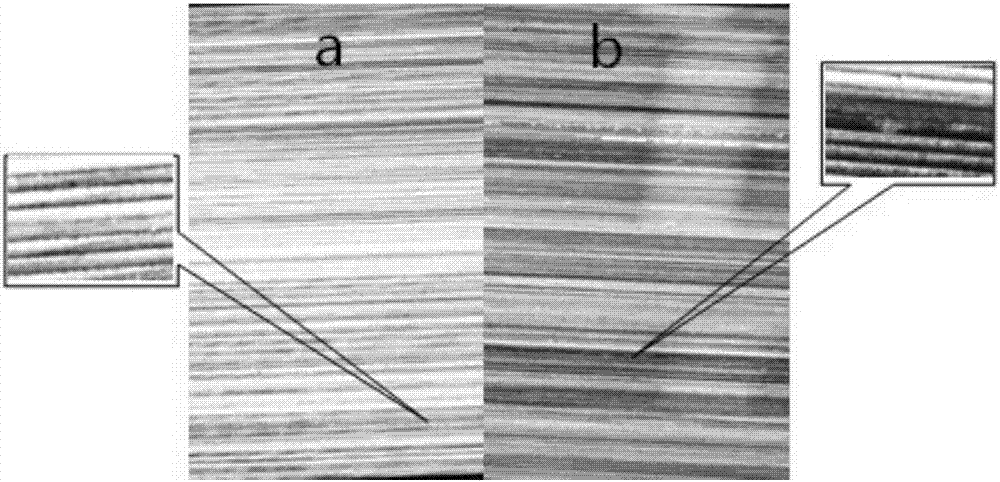

[0067] Step 1011, perform median filtering on the side image of the laminated silicon wafer or cell to remove the salt and pepper noise, such as image 3 As shown, among them, image 3 The picture in part a is the side image of the silicon wafer, and the picture in part b is the side image of the solar cell; due to the uneven illumination and the inherent characteristics of the side of the silicon wafer and the cell, it often appears on the obtained side image of the stacked silicon wafer or cell. The salt-and-pepper noise superimposed on the image in the form of black and white d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com