Supercapacitor that can be easily dismantled and recycled, manufacturing method and dismantling and recycling method

A technology of supercapacitor and recycling method, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor collectors, etc., and can solve the problems of electrode materials and collectors that are difficult to disassemble and recycle, environmental pollution, resource waste, etc. , to achieve low internal resistance, high volumetric energy density, and improved recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

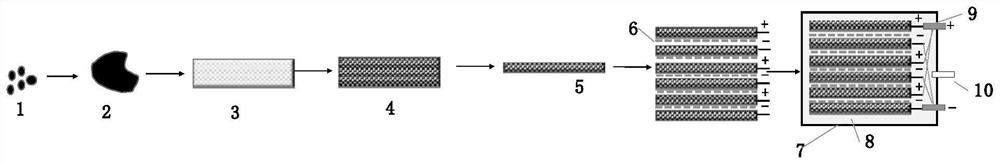

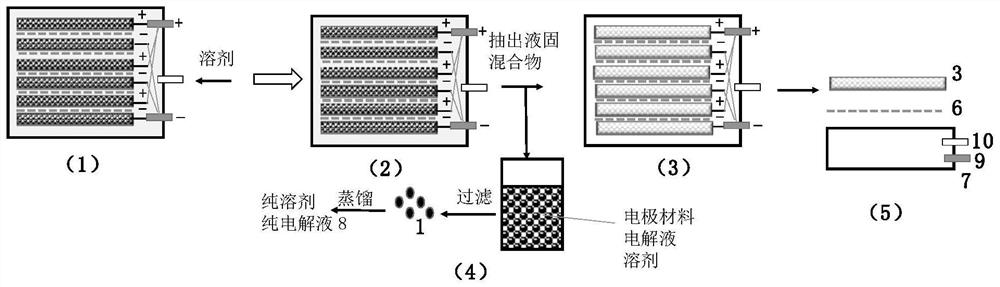

[0035] like figure 1 As shown, the electrode material 1 (carbon nanotubes with a particle size of 30 microns) was made into a slurry 2 according to a conventional method; by extrusion, it was filled into the metal current collector 3 (aluminum, the void size was In the gap of 10 times the maximum particle size of the electrode material), a composite pole piece 4 of the electrode material and the current collector is formed, and the two are in close contact by rolling to form a rolled composite pole piece 5. The rolled composite pole piece 5 is welded to the pole lug 9, separated by a diaphragm 6, and assembled in multiple pieces. The shell 7 of the aluminum plastic film is punched and formed, and the gas or liquid passage 10 is left on it. The assembled pole piece is encapsulated in the shell of the outer casing 7, and after dehydration, degassing and aging steps, the electrolyte 8 (ionic liquid) is injected, and then encapsulated to form a capacitor product. In normal use, ...

Embodiment 2

[0038] like figure 1 As shown, the electrode material 1 (manganese oxide and graphene, the mass fraction is 1:1, the particle size is 0.1 microns) is made into slurry 2 according to the conventional method; In the gap of the current collector 3 (platinum, the void size is 50 times the maximum particle size of the electrode material), a composite pole piece 4 of the electrode material and the current collector is formed, and the two are in close contact by rolling to form a roller. Press the composite pole piece 5. The rolled composite pole piece 5 is welded to the pole lug 9, separated by a diaphragm 6, and assembled in multiple pieces. The outer shell 7 of the stainless steel shell is stamped and formed, and a gas or liquid passage 10 is left on it. The assembled pole piece is encapsulated in the shell of the casing 7, and after dehydration, degassing and aging steps, the electrolyte 8 (KOH aqueous electrolyte) is injected, and then encapsulated to form a capacitor product....

Embodiment 3

[0041] like figure 1 As shown, the electrode material 1 (activated carbon, graphene, carbon nanofibers, mass ratio of 1:0.2:0.5, particle size 20 microns) was made into slurry 2 according to a conventional method; Filled into the gap of the metal current collector 3 (copper, the void size is 40 times the maximum particle size of the electrode material) to form a composite pole piece 4 of the electrode material and the current collector, and rolled to make the two close together contact to form a rolled composite pole piece 5 . The rolled composite pole piece 5 is welded to the pole lug 9, separated by a diaphragm 6, and assembled in multiple pieces. The copper casing 7 is stamped and formed, leaving a gas or liquid passage 10 on it. The assembled pole piece is encapsulated in the shell of the outer casing 7, and after dehydration, degassing and aging steps, the electrolyte 8 (organic electrolyte) is injected, and then encapsulated to form a capacitor product. In normal use,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com