New type domestic noodle machine

A noodle machine and household technology, applied in the direction of dough extruder, etc., can solve the problem of residual noodles, achieve high efficiency, speed up the efficiency of noodle feeding, and increase the speed of noodle making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

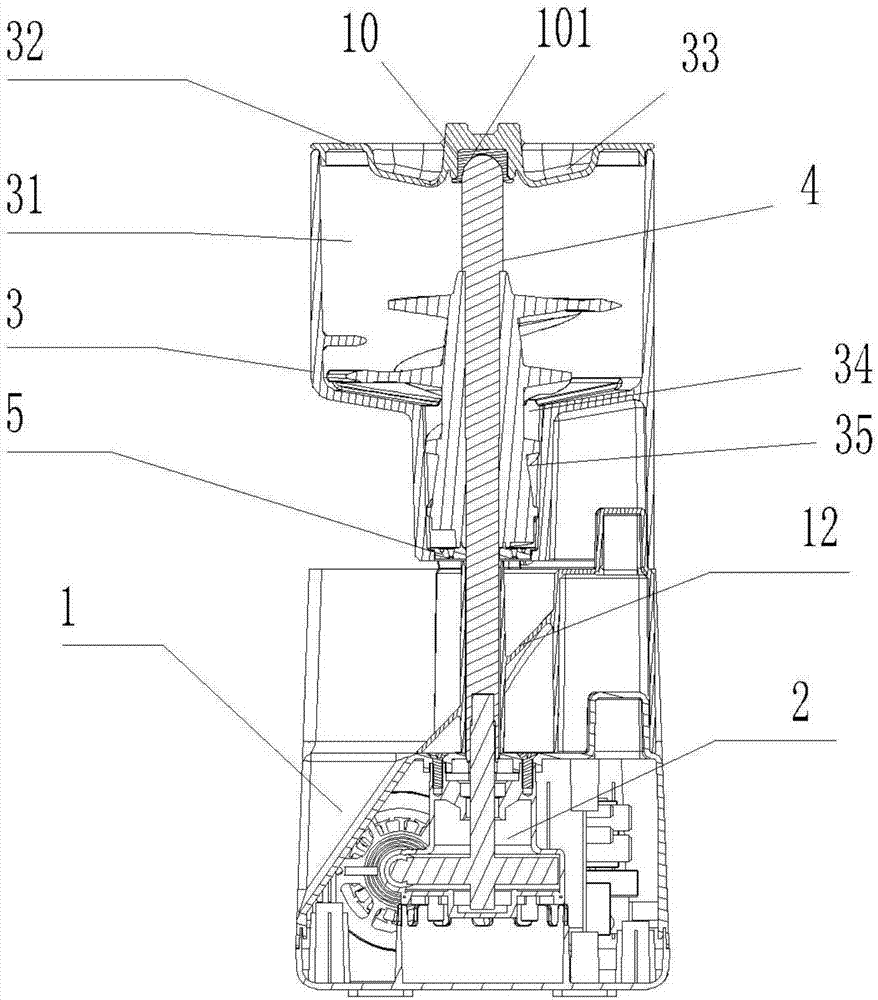

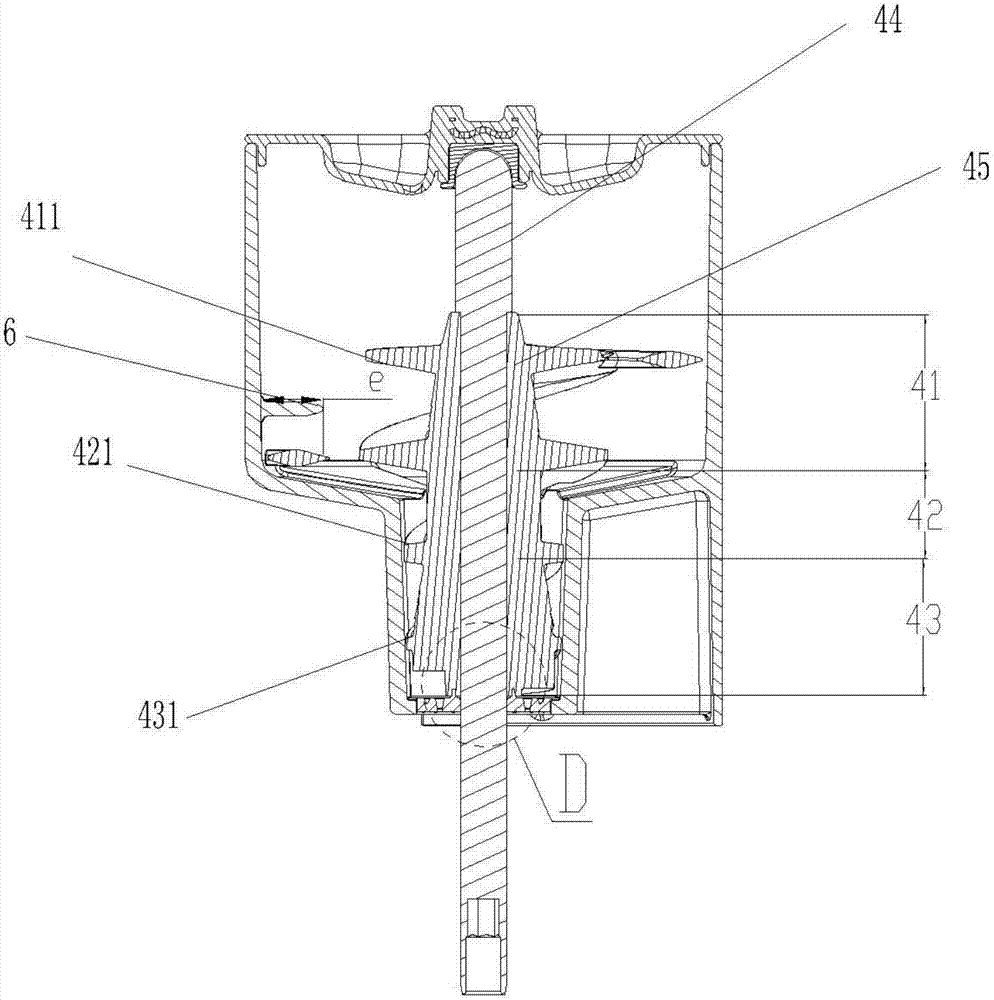

[0037] Such as figure 1 , figure 2 As shown, a new type of household noodle machine includes a machine base 1, a motor 2 arranged in the machine base 1, and a stirring cup 3 arranged on the machine base 1. In this embodiment, the machine base 1 is an L-shaped machine base. 1. It includes a fuselage and an extension wall extending upward from one side of the fuselage. The extension wall is provided with an operation panel, and the stirring cup 3 includes a stirring chamber 31 and a cup cover 32. The cup cover 32 is arranged on the stirring Above the chamber 31, the cup cover 32 is provided with a drip hole 33, the center of the bottom of the mixing chamber 31 is provided with a noodle inlet 34, and the noodle inlet 34 is provided with a noodle squeezing chamber below the mixing chamber 31. It communicates with the noodle-extruding chamber through the noodle inlet 34 and forms a processing chamber. A vertical processing assembly 4 is arranged in the processing chamber. The pro...

Embodiment 2

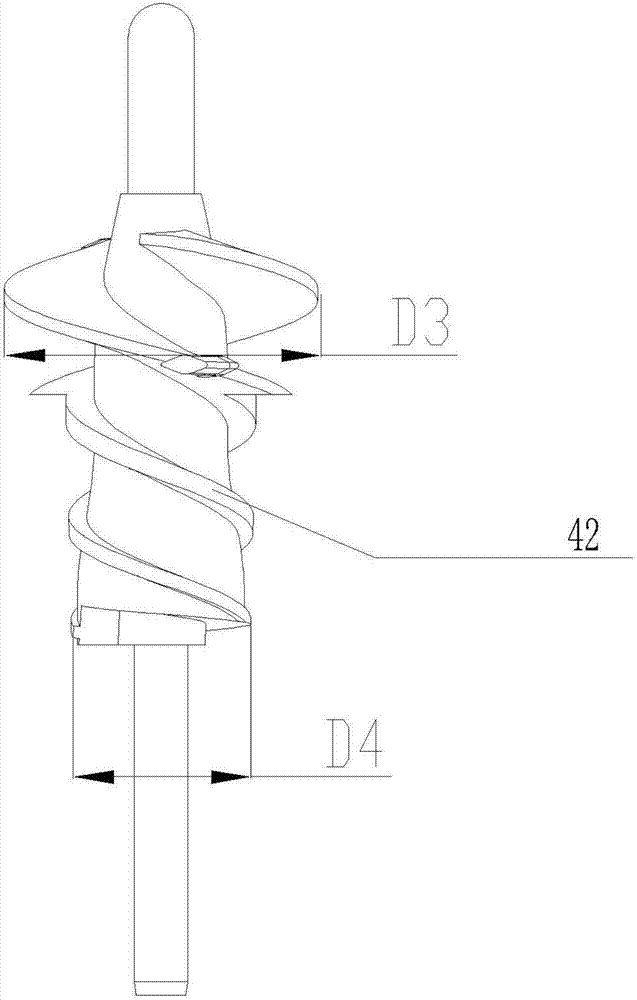

[0064] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the inner diameter of the noodle squeezing cavity gradually decreases from top to bottom, and the outer diameter of the screw body 45 has the same width from top to bottom. The outer diameter of the stirring screw 411 is greater than the inner diameter of the noodle inlet 34, so when dry flour is poured into the mixing chamber 31, it is not easy to drop into the noodle squeezing chamber. The outer diameter of the conveying screw 421 and the extruding screw 431 The outer diameters are all less than the inner diameter of the surface inlet 34. The advantage of this setting is that the inner diameter of the noodle extrusion cavity is gradually reduced from top to bottom, making it easier for the flour flocs / clusters in the mixing chamber 31 to enter the noodle extrusion cavity, that is, to improve the efficiency of entering the noodle, and to provide In order to...

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 is that in this embodiment, there are multiple guide surfaces 12, and they are arranged symmetrically along the drive axis of the motor 2. In this embodiment, there are two guide surfaces 12, so that The advantage of setting is that by setting multiple guide surfaces 12, the diversion in the direction of coming out is realized, the accumulation of dough is avoided, the efficiency of coming out is improved, and the noodles are prevented from sticking to the guide faces 12, so that the effect of coming out is better.

[0068] In this embodiment, the base 1 is provided with a guide surface at the lower end of the guide surface 12 , the guide surface is formed by a concave surface of the base 1 , and the guide surface is smoothly connected with the guide surface 12 . The advantage of this setting is that by setting the guide surface and the guide surface 12 to connect smoothly, the noodle sliding distance is extended du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com