Construction machinery supporting type hood device with reverse blowing cleansing assembly

A technology for purifying components and construction machinery, which is applied in the processing of building materials, construction, and building construction. It can solve the problems that affect the construction progress and time, the diameter of the cement nozzle becomes smaller, and the unevenness of the pipe wall achieves the guarantee. The effect of building construction progress, improving work efficiency, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

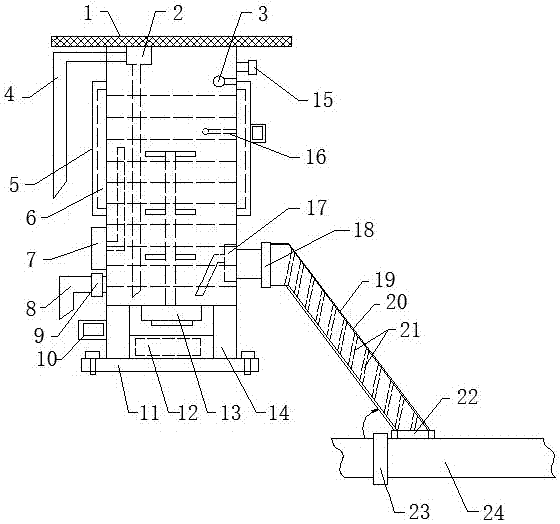

[0013] The present invention will be further explained below in conjunction with the drawings.

[0014] Such as figure 1 As shown, the supporting hood device with blowback purification components for construction machinery according to the present invention includes a mounting plate 11 on which a vertical water tank is provided, and the bottom of the vertical water tank is provided with supporting feet 14 The bottom surface of the vertical water tank is installed with a rotating motor 13, which is connected to a stirring paddle installed in the middle of the bottom surface of the vertical water tank; the vertical water tank mounting plate 11 is provided with a battery box in the middle of the surface, and the battery box is provided with Rechargeable battery 12; the lower left side of the vertical water tank is provided with a heater 7, and the heating rod of the heater 7 is installed on the left side of the vertical water tank; the top of the vertical water tank is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com