Glass sheet simple cleaning device and working process thereof

A technology for glass flakes and cleaning devices, which is applied in the direction of cleaning methods using liquids, cleaning flexible objects, cleaning methods, and utensils, and can solve problems such as high cost of ultrasonic cleaning, large surface damage of glass flakes, and easy collisions, etc. Maintenance rate and maintenance cost, low cost, soft cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

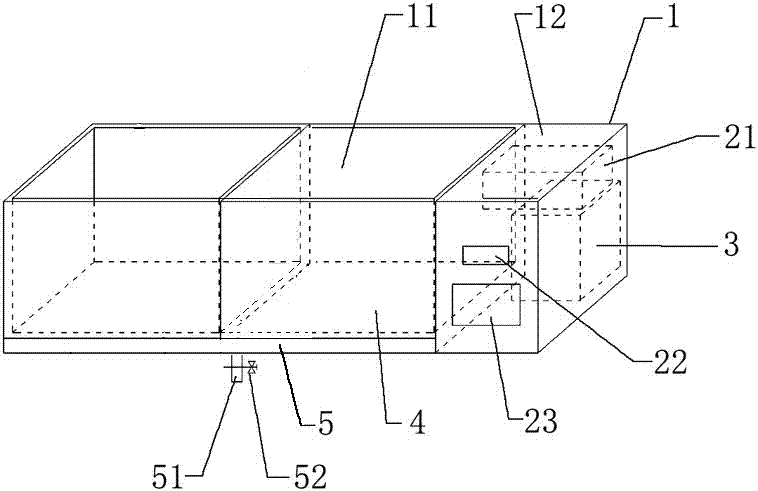

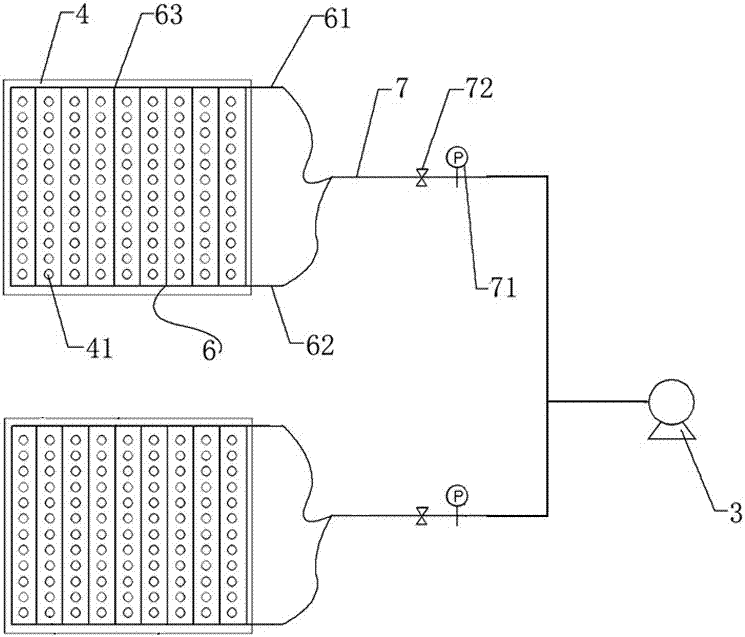

[0025] like figure 1 and figure 2 As shown, the simple cleaning device for glass flakes of the present invention includes a box body 1. The box body 1 includes a cleaning tank 11 and a relatively airtight control room 12 located on one side of the cleaning tank 11. The number of cleaning tanks 11 is 2-3, arranged side by side. , the control room 12 is provided with a control system and a blower 3, the control system includes a controller 21, a display screen 22 and a control panel 23, the display screen 22 and the control panel 23 are arranged on the outer wall of the control room 12, the signal input terminal of the display screen 22 is connected to the The signal output end of the controller 21 is electrically connected, and the signal output end of the control panel 23 is electrically connected with the signal input end of the controller 21; A buffer box 5 is arranged below the groove 11, and the height of the buffer box 5 does not exceed 12mm. A water outlet 51 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com