Cylinder pipe cutter

A cutter and bobbin technology, applied in metal processing and other directions, can solve the problems that bobbin cutting is not very efficient and convenient, operator safety hazards, inconvenient to apply force, etc., and achieves the effect of beautiful appearance, exquisite structure and easy collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

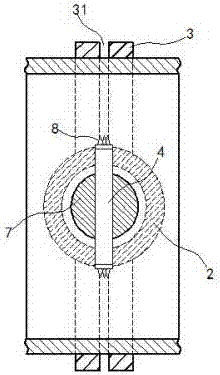

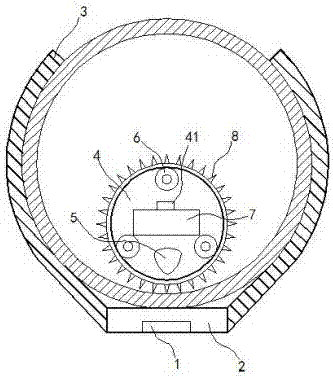

[0016] exist figure 1 , figure 2 In the illustrated embodiment, the bobbin cutter includes a base and a cutting portion,

[0017] The base includes an operating panel 1, a positioning ring 2 and a clamping arm 3 installed on the positioning ring 2, and the clamping arm 3 is made of elastic material; the operating panel 1 and the positioning ring 2 are powered by a battery; the positioning The ring 2 includes a permanent magnet ring; the clamping arm 3 is symmetrically distributed around the positioning ring 2; the clamping arm 3 is made of ferromagnetic material, and a crack 31 is opened on the clamping arm 3 ;

[0018] The cutting part includes a power disc 4, and a power supply, a controller 41, a gyro stabilizer 5 and a driver 6 are arranged in the power disc 4; 4; the gyro stabilizer 5, the controller 41 and the driver 6 are electrically connected to the power supply, and the controller 41 is wirelessly matched and connected to the operation panel 1; a positioner 7 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap