Production, demolding, board-taking and stacking device for gypsum boards

A gypsum board and board stacking technology is applied in the field of gypsum board production demoulding board removal and stacking devices, which can solve the problems of low production efficiency and high labor intensity, and achieve the effects of convenient operation, improved device reliability and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

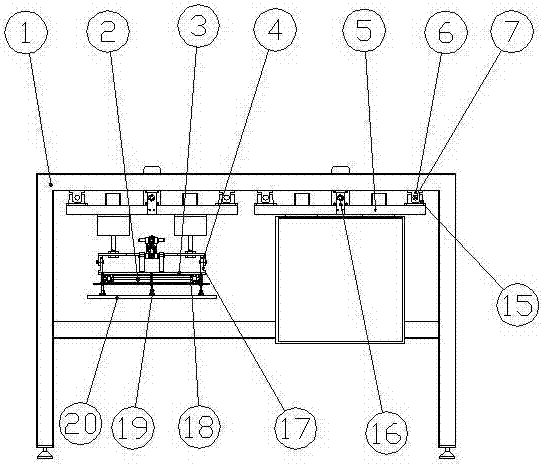

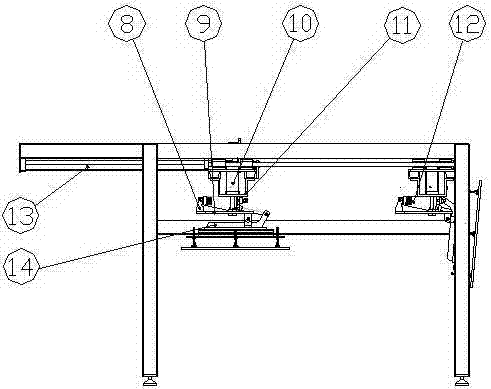

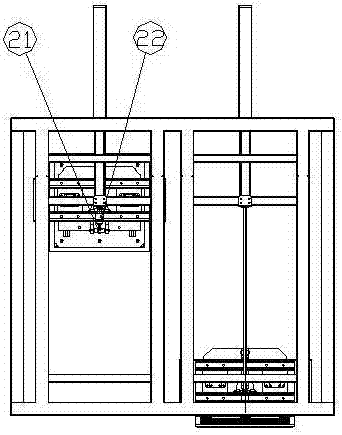

[0021] The invention provides a stripping and stacking device for gypsum board production, which is to provide a stripping and stacking device for gypsum board production, which has a high degree of automation and is easy to use, and can remove the gypsum board from Take it out from the mold, send the plasterboard in the horizontal state out of the conveying line, and switch to the inclined state and stack it on the push plate trolley, automatically complete the removal of the plasterboard from the mold, send it out of the conveying line, turn it over at a certain inclination angle, and then automatically stack it Put it on the pushing trolley to complete the working process of the gypsum board from demoulding and taking to automatic stacking as required.

[0022] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the accompanying drawings of the embodiments of the present invention, but the following em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com