Rain boot upper two-color or multi-color molding method and mold

A technology for molding molds and molding methods, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as low efficiency, inability to realize mechanized production, and dependence on labor, and achieve high efficiency, easy mechanized operation, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

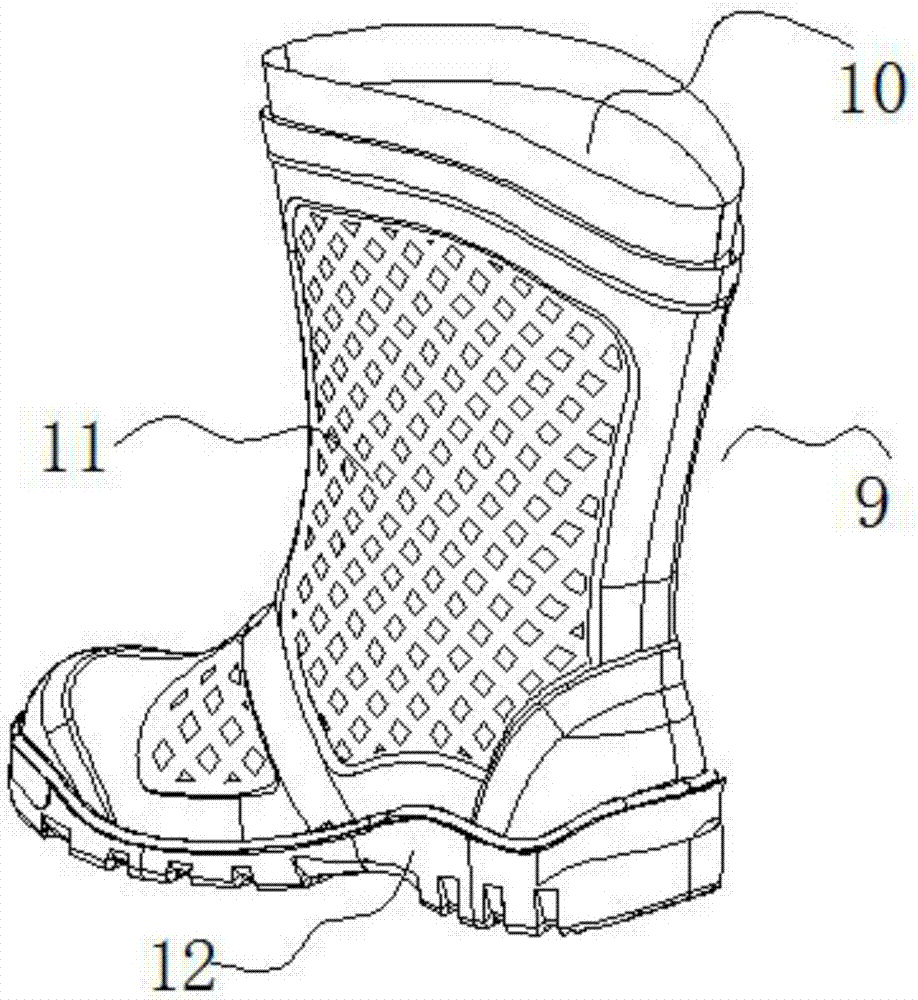

[0023] see Figures 1 to 3 The two-color or multi-color molding method for the upper surface of rain boots provided in this embodiment includes the following steps:

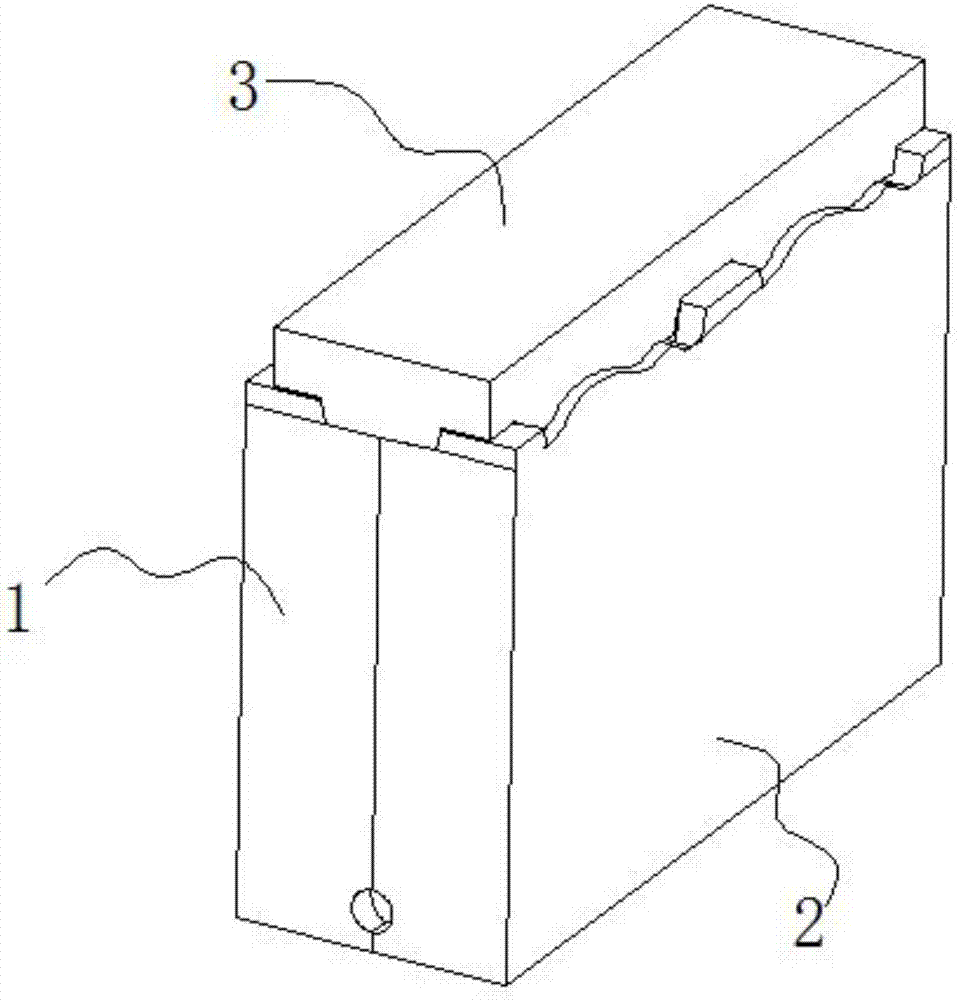

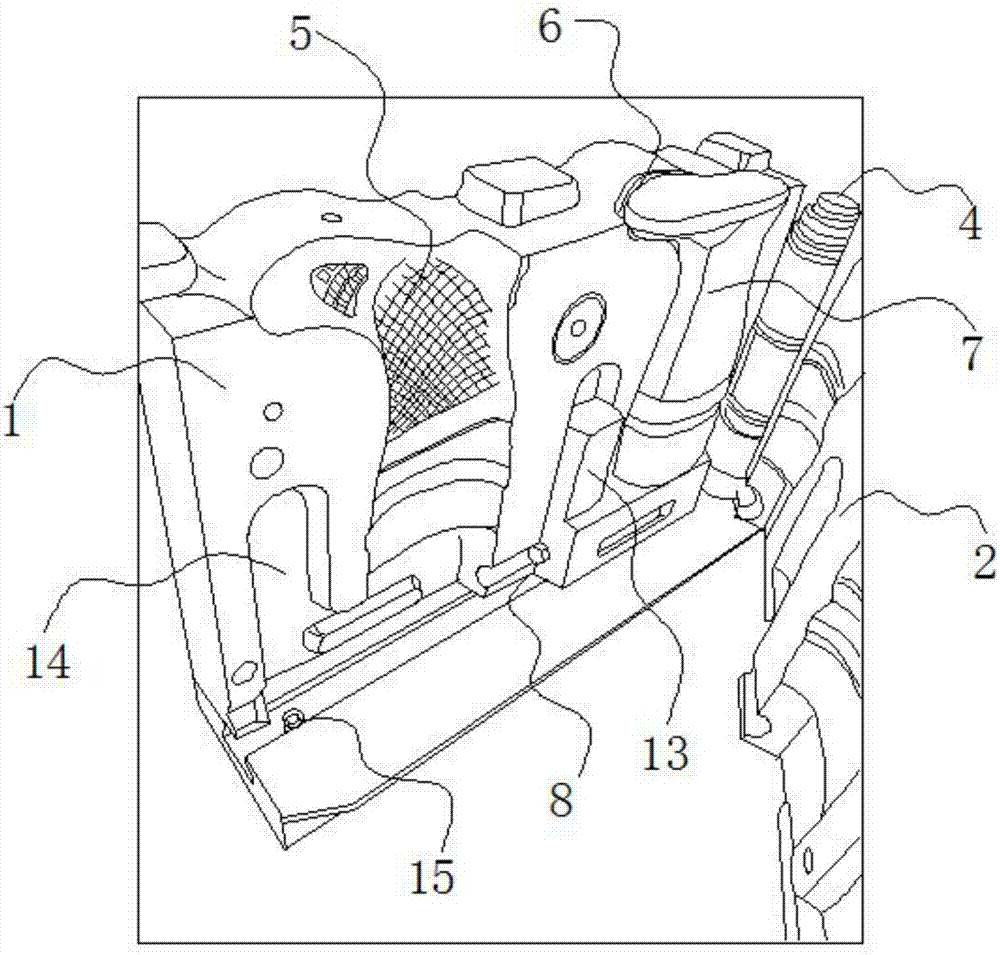

[0024] 1) Set up a forming mold, including the main mold body 1, the auxiliary mold body 2 and the upper mold body 3, the main mold body 1 and the auxiliary mold body 2 are hingedly connected by the hinge structure 4, the upper mold body 3 and the main mold body 1 Or the auxiliary mold body 2 is hingedly connected by a hinge structure; wherein, the inner sides of the main mold body 1, the auxiliary mold body 2 and the upper mold body 3 cooperate to form the first cavity 5 and the second cavity 6; the shoe last type The core 7 is arranged inside the main mold body 1 through the sliding structure 8, so as to realize the conversion between the first cavity 5 and the second cavity 6, wherein the shoe last core 7 cooperates with the first cavity 5 to form the second cavity. One-color molding space, the shoe last core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com