An electronically controlled hydraulic power-assisted brake master cylinder

An electronically controlled hydraulic and brake master cylinder technology, applied in the direction of hydraulic brake transmission, brake, brake transmission, etc., can solve the problems of inaccurate pressure adjustment, large vibration and noise, complex structure, etc., and improve system safety The effects of stability, elimination of noise sources, and low probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

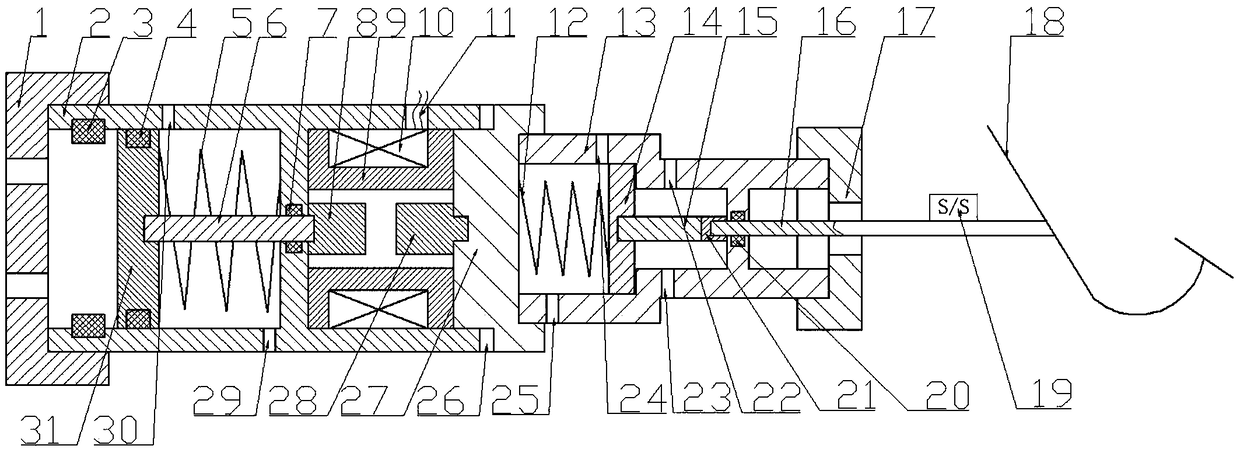

[0049] refer to figure 1 , an electronically controlled hydraulic power-assisted brake master cylinder according to the present invention is composed of an electromagnetic booster mechanism and a three-chamber master cylinder mechanism.

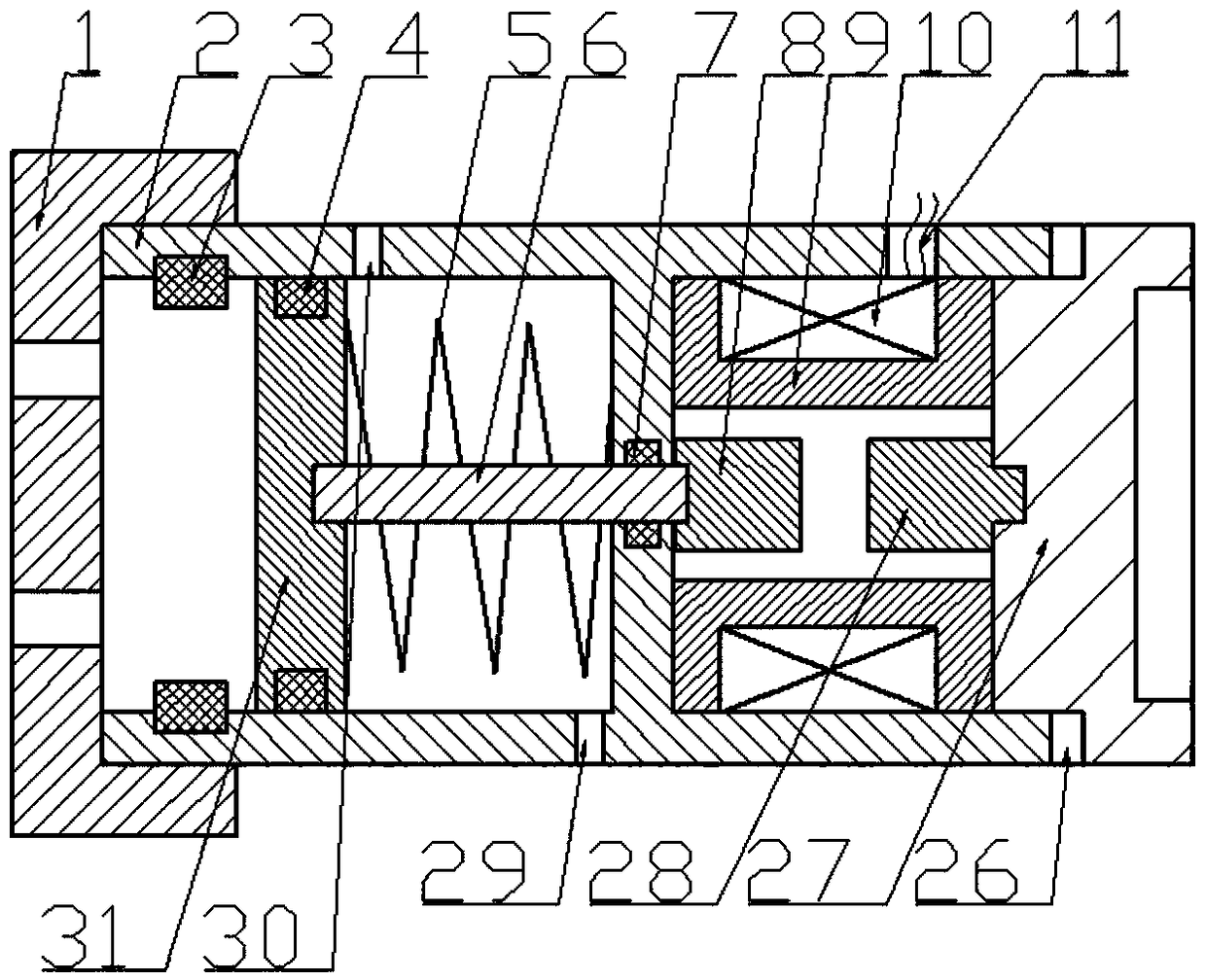

[0050] refer to figure 2 , the electromagnetic boosting mechanism is composed of a hydraulic part and an electromagnetic part.

[0051] The structure of the hydraulic part of the electromagnetic booster mechanism is:

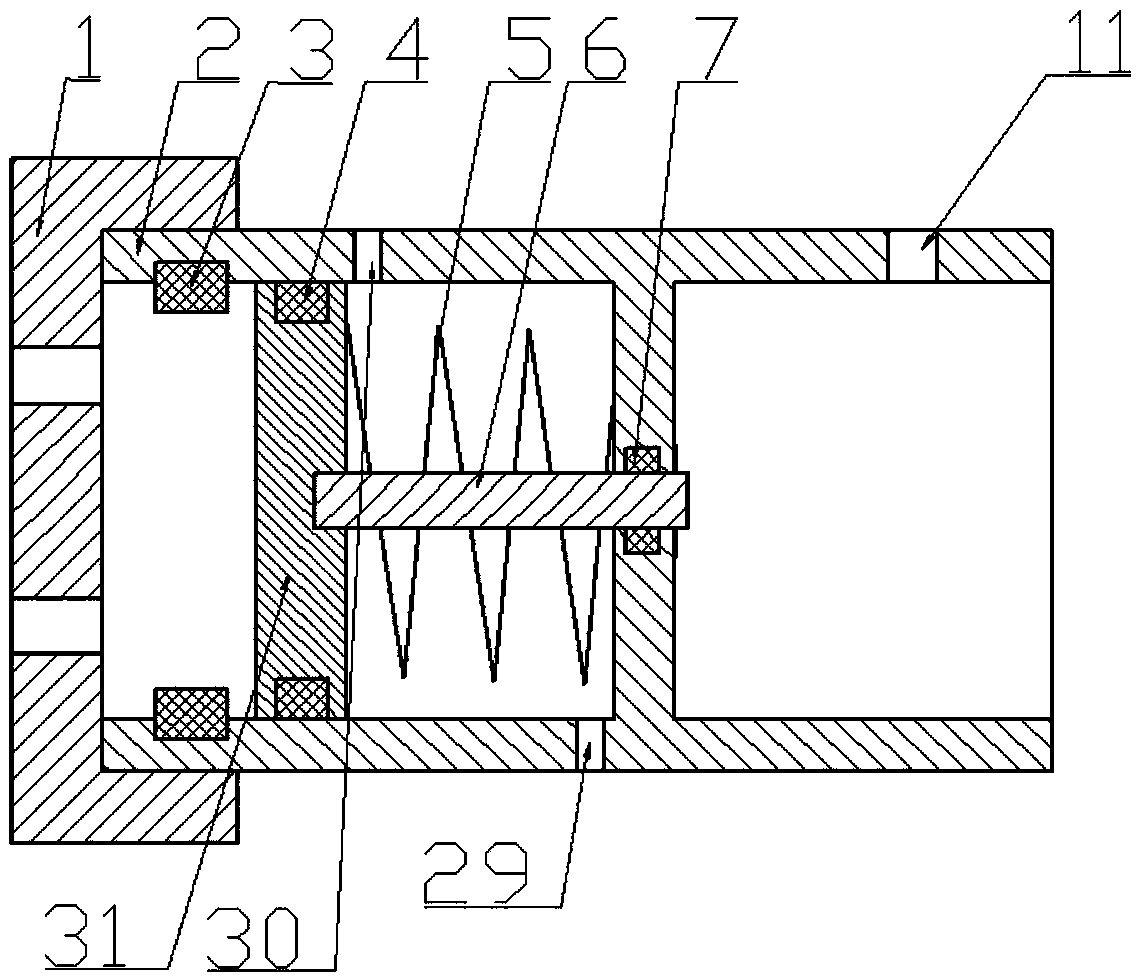

[0052] refer to image 3 , the hydraulic part of the electromagnetic boosting mechanism is composed of a booster hydraulic cylinder end cover 1, a booster hydraulic cylinder body 2, a rubber stopper 3, a piston seal ring 4, a booster hydraulic cylinder return spring 5, a booster hydraulic cylinder piston rod 6, Piston rod sealing ring 7, booster hydraulic cylinder piston 31 are formed. Its main function is to generate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com