A sma-driven helical thermally variable stiffness active control mechanism

An active control and variable stiffness technology, which is applied in the aerospace field, can solve the problems of weak stiffness change control effect, small control force, and large limitation, and achieve a significant stiffness change control effect and the effect of ensuring stiffness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

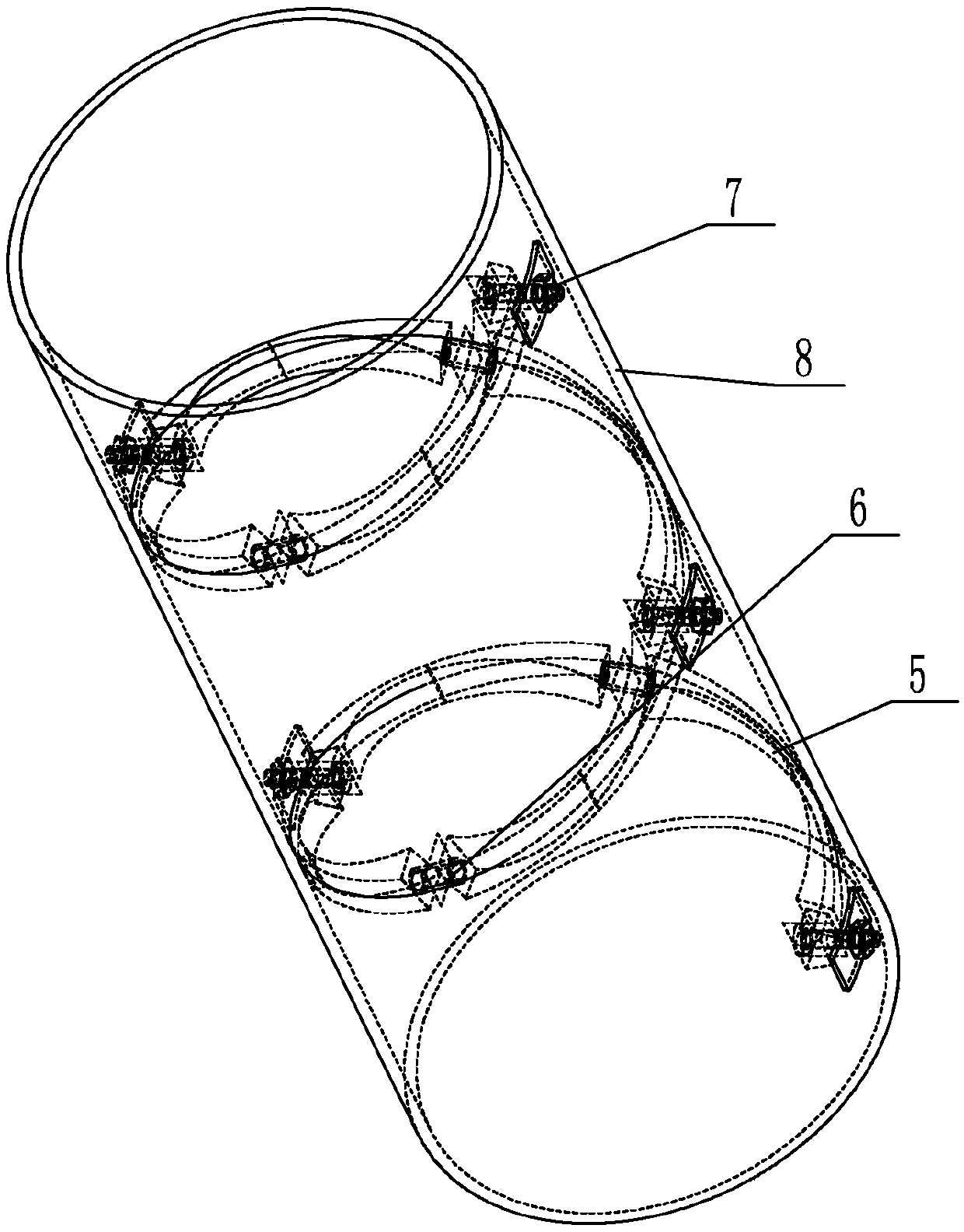

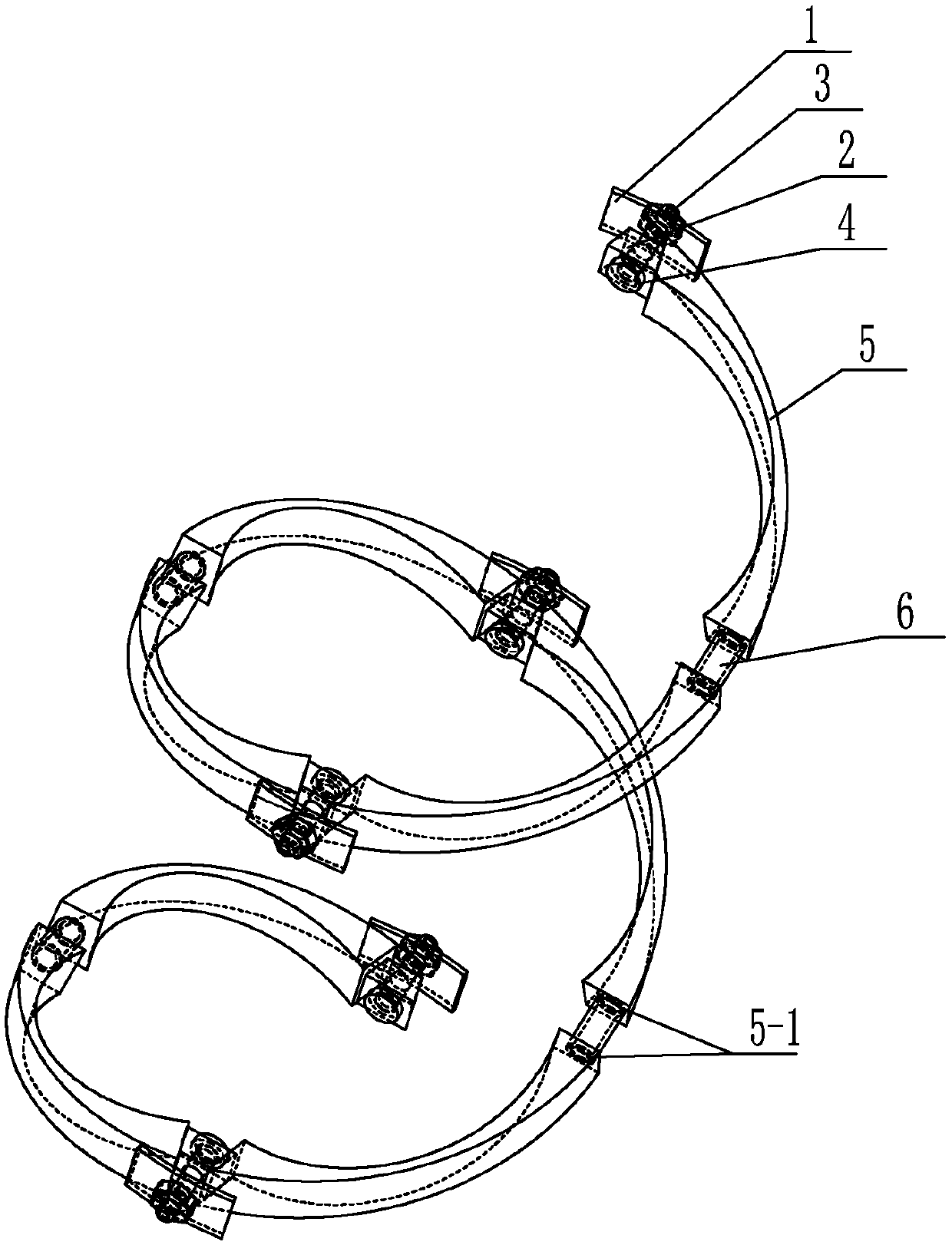

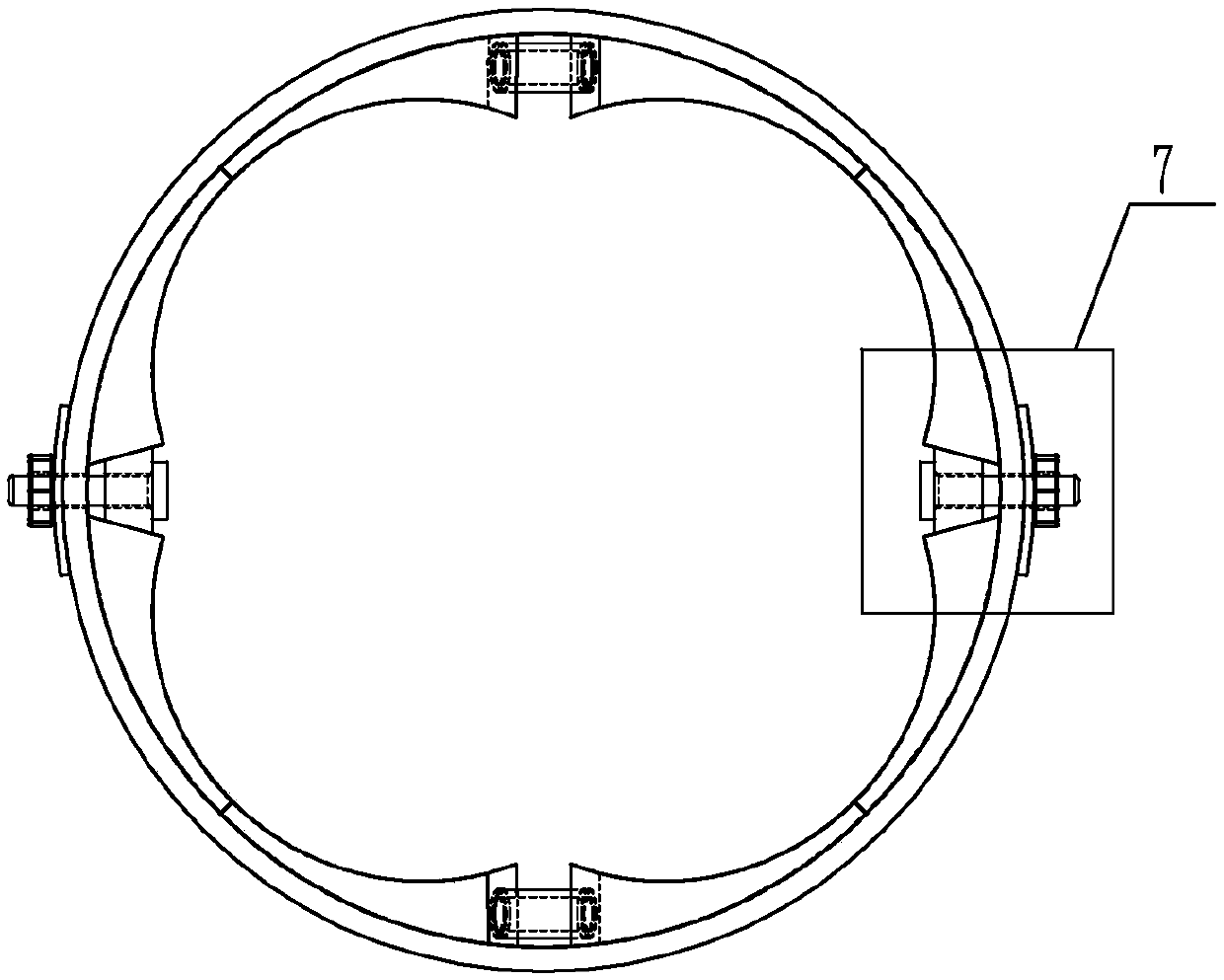

[0018] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, an SMA-driven helical thermally variable stiffness active control mechanism described in this embodiment includes a plurality of quarter helical expansion rings 5, a plurality of SMA-driven circular tubes 6 and a plurality of pretensioning mechanisms 7, A plurality of quarter helical expansion rings 5 are helically arranged on the inner wall of the cylindrical thin shell 8, the beginning of the first quarter helical expansion ring 5 and the end of the last quarter helical expansion ring 5 pass through The pre-tensioning mechanism 7 is fixedly connected with the thin cylindrical shell 8, and two adjacent quarter spiral expansion rings 5 are connected by SMA driving circular tubes 6 or pre-tensioning mechanisms 7, multiple SMA driving circular tubes 6 and multiple pre-tensioning mechanisms 7 alternate settings.

[0019] This embodiment relates to a thermally variable stiffn...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 1 to Figure 3 To describe this embodiment, the outer surface of the SMA drive tube 6 in this embodiment is provided with a polyimide heating film. Other compositions and connection methods are the same as those in Embodiment 1.

[0025] In this embodiment, the outer surface of the SMA driving tube 6 is wrapped with polyimide heating film, so that it can be evenly heated during the working process. When working, provide a suitable voltage for the heating film wrapped on the outer surface of the SMA driving round tube 6 .

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1 to Figure 3 The present embodiment is described. The two end faces of the SMA driving circular pipe 6 in this embodiment are respectively affixed to the end faces of the quarter helical expansion ring 5 . Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0027] Such a design makes the SMA driving circular tube 6 directly act on the end surface of the quarter helical expansion ring 5 from the end when the SMA driving circular tube 6 is heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com