A kind of high swelling resistance fluorosilicone raw rubber and preparation method thereof

A technology of fluorosilicone raw rubber and swelling properties, which is applied in the field of high anti-swellable fluorosilicone raw rubber and its preparation, can solve the problem of increasing the cost of fluorine-containing polysiloxane macromolecular polymers, insufficient anti-swelling, siloxane To solve the problems of high price of cyclic compounds, achieve excellent mechanical properties and thermal stability, avoid adverse effects, and have good swelling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

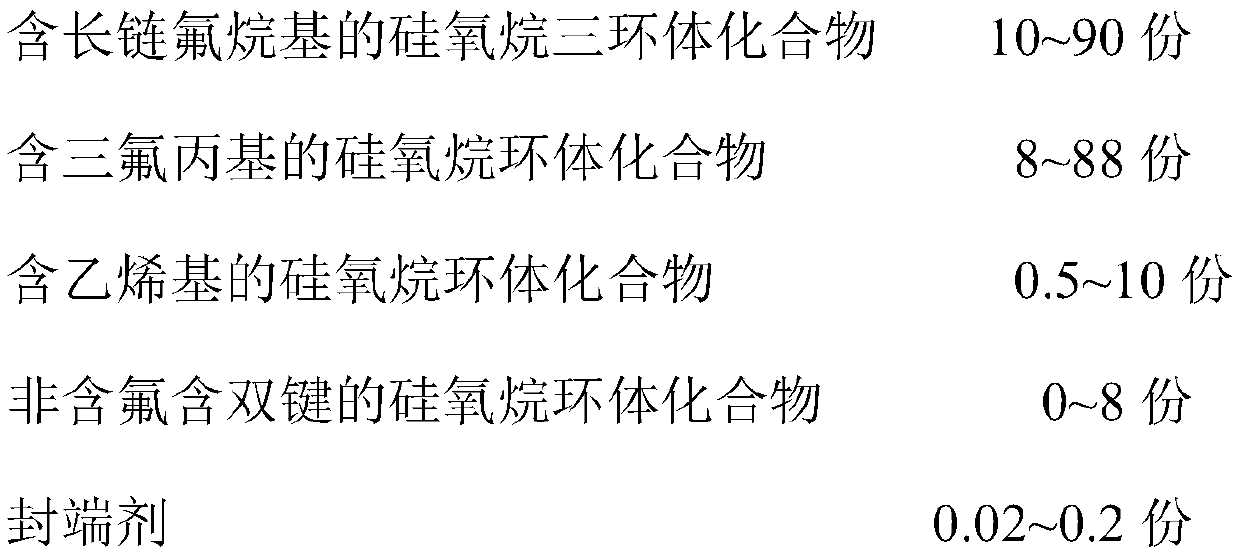

Method used

Image

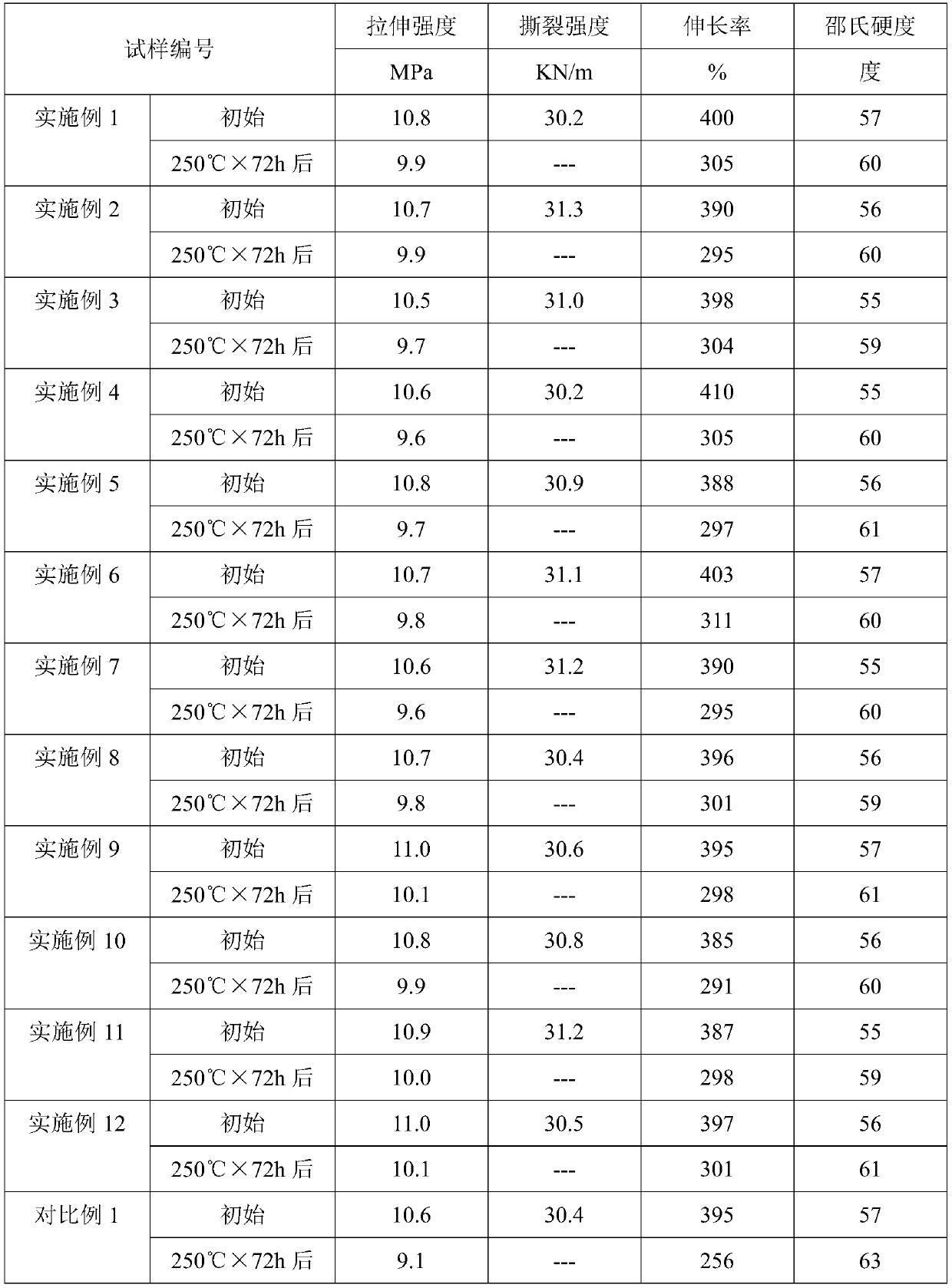

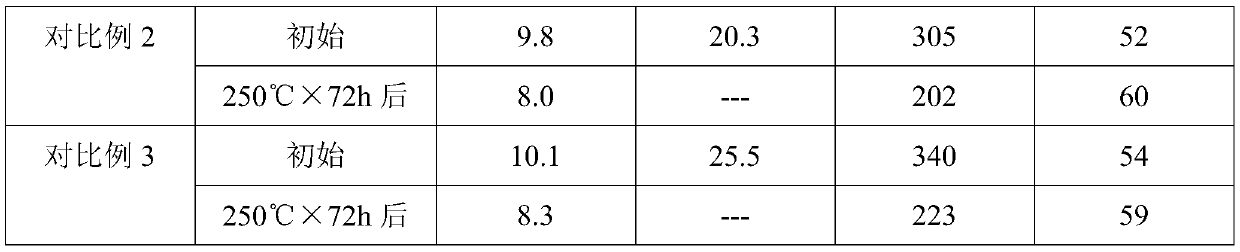

Examples

Embodiment 1

[0041] First, 50 parts by mass of siloxane tricyclic compounds containing long-chain fluoroalkyl groups (Si(CH 3 )(CH 2 CH 2 CF 2 CF 2 CF 2 CF 3 )O) 3 And 45 parts by mass of trifluoropropyl-containing siloxane ring compound D 3 Add F into the three-necked flask, stir and heat to 80°C, dehydrate under reduced pressure for 1.5h; then cool down to the reaction temperature of 65°C, add 4.9 parts by mass of vinyl-containing siloxane ring compound D 3 Vi, 0.1 parts by mass of blocking agent Vi 2 Carry out ring-opening polymerization reaction with 0.1 mass part of acidic catalyst fuming sulfuric acid, and the reaction time is 20h; When the material viscosity reaches a predetermined value, stop the reaction, wash the crude product with water to neutrality, and remove low boilers in the crude product under reduced pressure , get high anti-swelling fluorosilicone raw rubber.

Embodiment 2

[0043] First, 10 parts by mass of siloxane tricyclic compounds containing long-chain fluoroalkyl groups (Si(CH 3 )(CH 2 CH 2 CF 2 CF 2 CF 2 CF 3 )O) 3 And 88 parts by mass of trifluoropropyl-containing siloxane ring compound D 3 Add F into the three-necked flask, stir and heat to 140°C, dehydrate under reduced pressure for 0.5h; then cool down to the reaction temperature of 110°C, add 1.95 parts by mass of vinyl-containing siloxane ring compound D 3 Vi, 0.05 parts by mass of blocking agent Vi 4 and 0.04 parts by mass of acidic catalyst oleum to carry out ring-opening polymerization reaction, the reaction time is 8h; when the viscosity of the material reaches a predetermined value, stop the reaction, wash the crude product with water to neutrality, and remove the low boilers in the crude product under reduced pressure , get high anti-swelling fluorosilicone raw rubber.

Embodiment 3

[0045] First, 90 parts by mass of siloxane tricyclic compounds containing long-chain fluoroalkyl groups (Si(CH 3 )(CH 2 CH 2 CF 2 CF 2 CF 2 CF 3 )O) 3 , 8 parts by mass of trifluoropropyl-containing siloxane ring compound D 4 F and 1 mass part non-fluorine-containing double bond-containing siloxane ring compound D 4 Add it into a three-necked flask, stir and heat to 120°C, dehydrate under reduced pressure for 1 hour; then cool down to the reaction temperature of 90°C, add 0.95 parts by mass of vinyl-containing siloxane ring compound D 4 Vi, 0.05 parts by mass of blocking agent Vi 2 Carry out ring-opening polymerization reaction with 1 mass part of acid catalyst fuming sulfuric acid, and the reaction time is 15h; When the viscosity of the material reaches a predetermined value, stop the reaction, wash the crude product with water to neutrality, and remove the low boilers in the crude product under reduced pressure , get high anti-swelling fluorosilicone raw rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com