Cationic polymer containing branched structure, and preparation method and application thereof

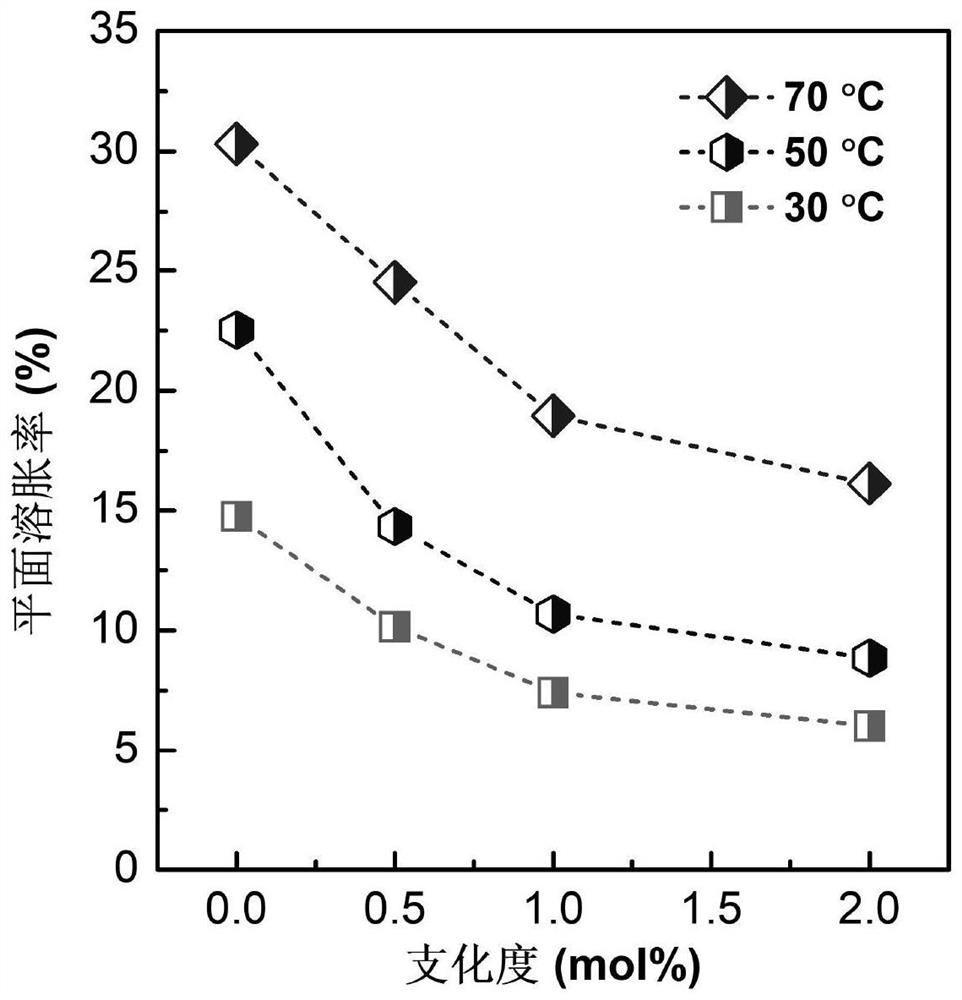

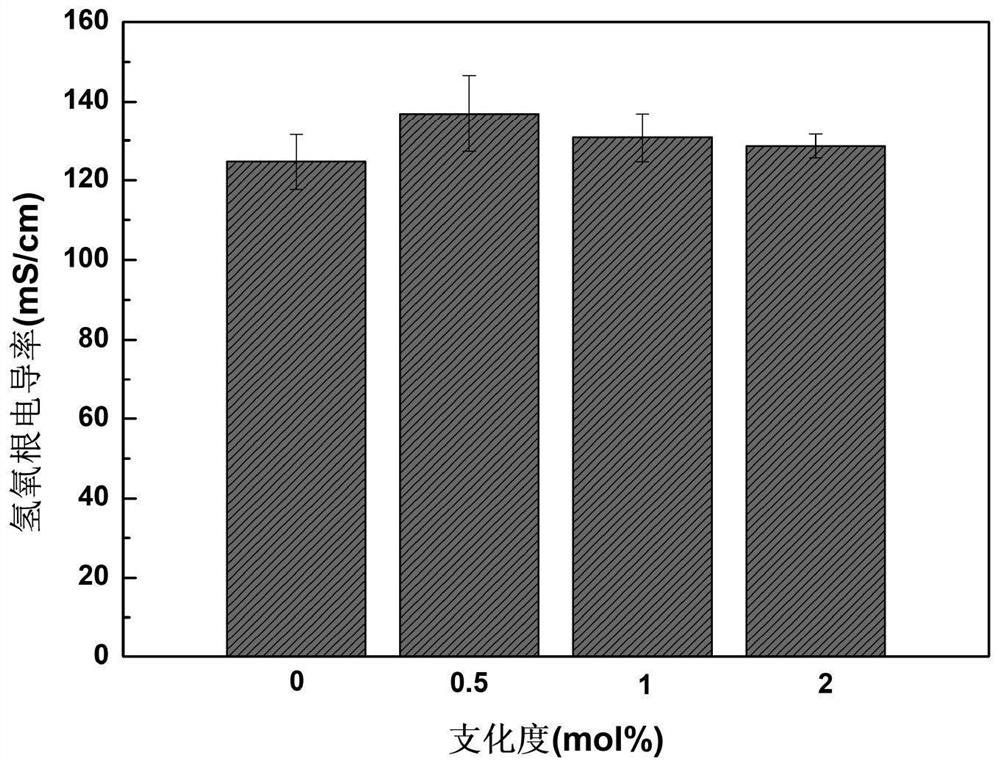

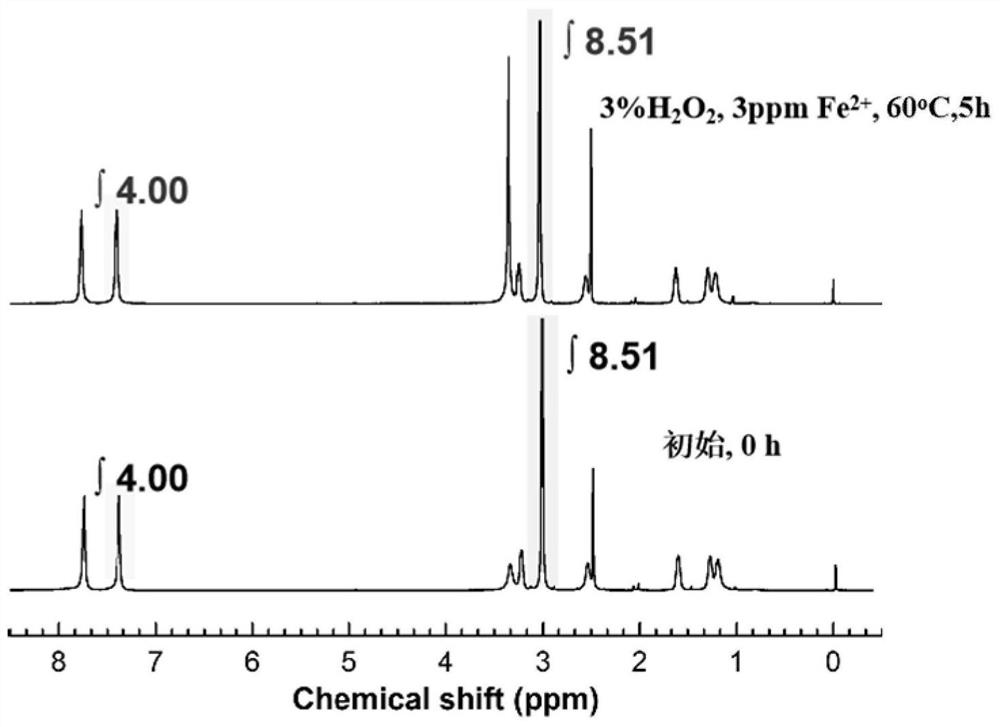

A technology of cationic polymers and branched structures, which is applied in the field of anion exchange membrane materials, can solve problems such as damage to the stability of anion membranes, and achieve the effect of improving alkali resistance, anti-oxidation stability, and good anti-swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In the present embodiment, the cationic polymer containing branched structure has the structural formula shown in formula (6):

[0061]

[0062] The specific method is: biphenyl (0.3g, 1.945mmol), 7-bromo-1,1,1-trifluoroheptan-2-one (0.5313g, 2.1506mmol), 1,3,5-triphenylbenzene ( 0.00298g, 9.727×10 -3 mmol), dichloromethane (2 mL) and trifluoromethanesulfonic acid (2 mL) were reacted at room temperature for 24 h to obtain a viscous polymer solution. After the reaction was completed, it was slowly added dropwise into methanol to obtain a white thick fibrous polymer. It is then filtered and washed well. After vacuum drying, 0.83 g of a white fibrous bromine-terminated polymer precursor was obtained.

[0063] The bromine-terminated polymer precursor was then dissolved in 15 mL of N-methylpyrrolidone, and a solution of 2.6 mL of trimethylamine (4.2 mol L -1 ethanol solution), after reacting at room temperature for 72 hours, the reaction system was slowly added to anh...

Embodiment 2

[0068] In the present embodiment, the cationic polymer containing branched structure has the structural formula shown in formula (7):

[0069]

[0070] The specific method is: m-terphenyl (0.6g, 2.6063mmol), 7-bromo-1,1,1-trifluoroheptan-2-one (0.722g, 2.9231mmol), 1,3,5-triphenyl Benzene (0.0159g, 5.21×10 -2 mmol), dichloromethane (2.6 mL) and trifluoromethanesulfonic acid (2.6 mL) were stirred at room temperature for 24 h to give a black gel-like material. After the reaction was completed, it was slowly added dropwise into methanol to obtain a white thick fibrous polymer. It is then filtered and washed well. After vacuum drying, 1.31 g of bromine-terminated precursor polymer was obtained as white fibers.

[0071] The bromine-terminated precursor polymer was then dissolved in 15 mL of N-methylpyrrolidone, and a solution of 2.2 mL of trimethylamine (4.2 mol L -1 ethanol solution), after reacting at room temperature for 72 hours, the reaction system was slowly added to a...

Embodiment 3

[0076] In the present embodiment, the cationic polymer containing branched structure has the structural formula shown in formula (8):

[0077]

[0078] The specific method is: biphenyl (0.3g, 1.945mmol), 7-bromo-1,1,1-trifluoroheptan-2-one (0.5313g, 2.1506mmol), 1,3,5-triphenylbenzene ( 0.00298g, 9.727×10 -3 mmol), dichloromethane (2 mL) and trifluoromethanesulfonic acid (2 mL) were stirred at room temperature for 24 h to give a black gel-like material. After the reaction was completed, it was slowly added dropwise into methanol to obtain a white thick fibrous polymer. It is then filtered and washed well. After vacuum drying, 0.67 g of bromine-terminated precursor polymer was obtained as white fibers.

[0079]Then the bromine-terminated precursor polymer was dissolved in 15 mL N-methylpyrrolidone, 1.51 mL N-methylpiperidine was added, and after 72 hours of reaction at room temperature, the reaction system was slowly added to anhydrous ether to obtain 0.7 g off-white fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com