High-strength anti-swelling chitosan-based physical hydrogel and preparation method thereof

A chitosan and anti-swelling technology, applied in the field of semi-interpenetrating network hydrogel, can solve the problems of original performance damage and limited practicality, and achieve excellent mechanical properties, good biocompatibility, excellent mechanical properties and Effect of anti-swelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

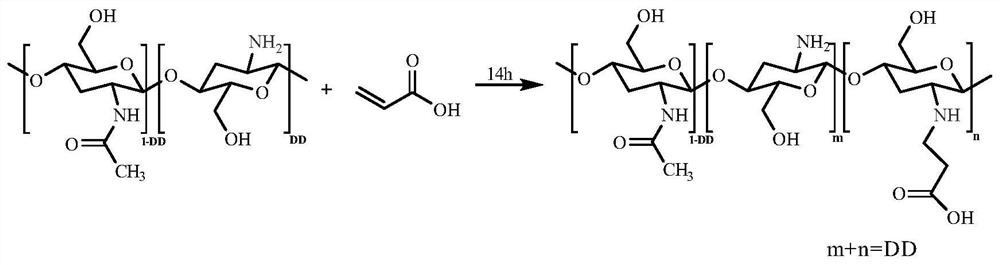

[0025] 1) Weigh 4g of chitosan with a viscosity-average molecular weight of 20w and a deacetylation degree of 90%, and disperse it in 200mL of deionized water, add 5.84mL (85.2mmol) of acrylic acid, stir and dissolve, and react at 60°C for 16h. After the reaction, adjust the pH of the product to 10-12 with sodium hydroxide solution, then dialyze with a dialysis bag for 5 days, and freeze-dry to obtain CEC;

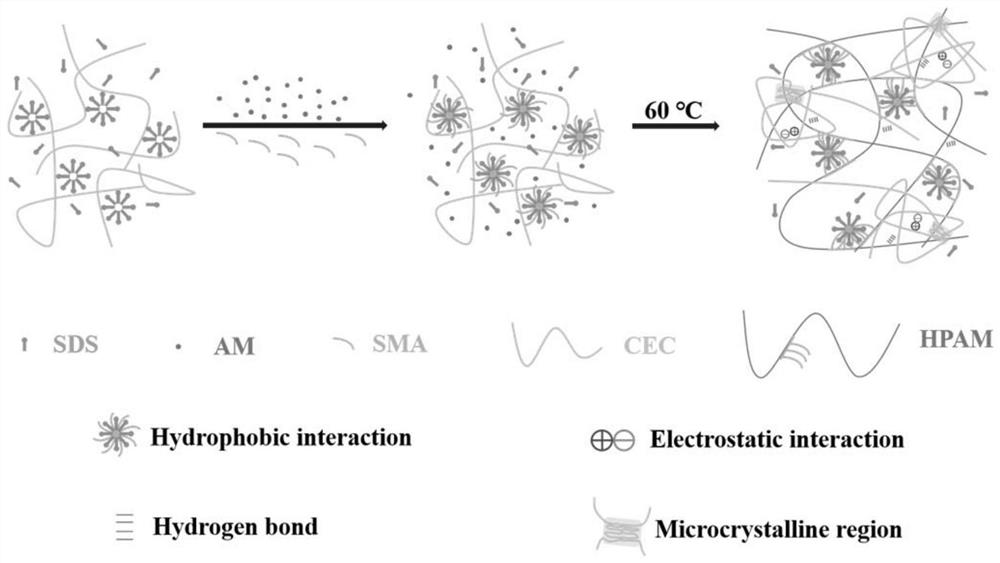

[0026] 2) Add 4g SDS and 5.265g NaCl to 100mL deionized water to prepare solution A;

[0027] 3) Take 5mL of the above solution A, add 0.025g of CEC into it, stir evenly to obtain a uniform and transparent solution, then add 1g of AM and 109μL of SMA in turn, stir and dissolve to obtain solution B;

[0028] 4) Add 50 μL of APS solution (0.1g / mL) to the above solution B, stir evenly to obtain a pre-polymerized solution, quickly inject it into the mold, and ultrasonically remove air bubbles;

[0029] 5) Place the mold filled with the pre-polymerization solution at 60°C for ...

Embodiment 2

[0033] 1) Weigh 4g of chitosan with a viscosity-average molecular weight of 20w and a deacetylation degree of 90%, and disperse it in 200mL of deionized water, add 5.84mL (85.2mmol) of acrylic acid, stir and dissolve, and react at 60°C for 16h. After the reaction, adjust the pH of the product to 10-12 with sodium hydroxide solution, then dialyze with a dialysis bag for 5 days, and freeze-dry to obtain CEC;

[0034] 2) Add 4g SDS and 5.625g NaCl to 100mL deionized water to prepare solution A;

[0035] 3) Take 5mL of the above solution A, add 0.05g of CEC to it, stir evenly to obtain a uniform and transparent solution, then add 1g of AM and 109μL of SMA in turn, fully stir and dissolve to obtain solution B;

[0036]4) Add 50 μL of APS solution (0.1g / mL) to the above solution B, stir evenly to obtain a pre-polymerized solution, quickly inject it into the mold, and ultrasonically remove air bubbles;

[0037] 5) Place the mold filled with the pre-polymerization solution at 60°C fo...

Embodiment 3

[0040] 1) Weigh 4g of chitosan with a viscosity average molecular weight of 20w and a deacetylation degree of 90%, and disperse it in 200mL of deionized water, add 5.84mL (85.2mmol) of acrylic acid, stir and dissolve, and react at 60°C for 16h. After the reaction, adjust the pH of the product to 10-12 with sodium hydroxide solution, then dialyze with a dialysis bag for 5 days, and freeze-dry to obtain CEC;

[0041] 2) Add 4g SDS and 5.625g NaCl to 100mL deionized water to prepare solution A;

[0042] 3) Take 5mL of the above solution A, add 0.075g of CEC into it, stir evenly to obtain a homogeneous and transparent solution, then add 1g of AM and 109μL of SMA in turn, stir well and dissolve to obtain solution B;

[0043] 4) Add 50 μL of APS solution (0.1g / mL) to the above solution B, stir evenly to obtain a pre-polymerized solution, quickly inject it into the mold, and ultrasonically remove air bubbles;

[0044] 5) Place the mold filled with the pre-polymerization solution at ...

PUM

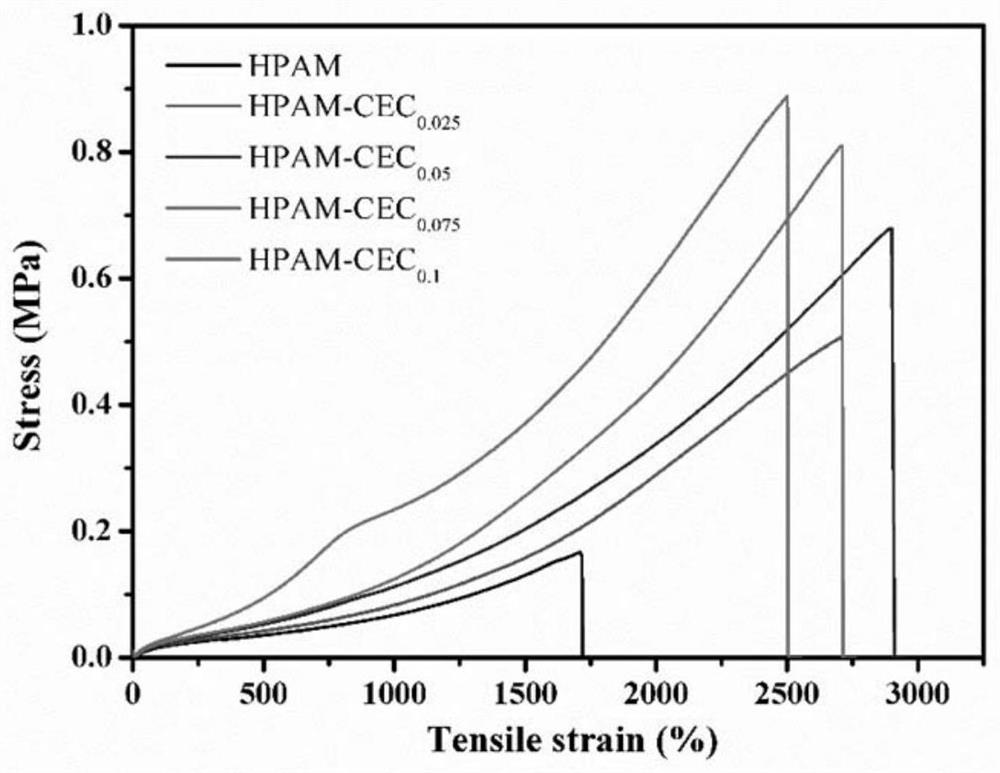

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com