Preparation method of MIL-100 (Fe)/PDMS film

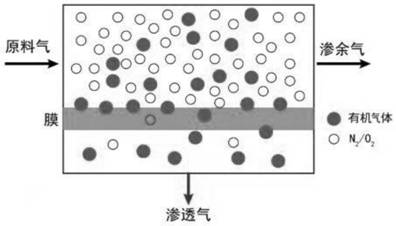

A technology of bottom membrane and casting liquid, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problem of low separation factor of organic gas, and achieve the effect of improving separation factor, good separation effect and good anti-swelling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

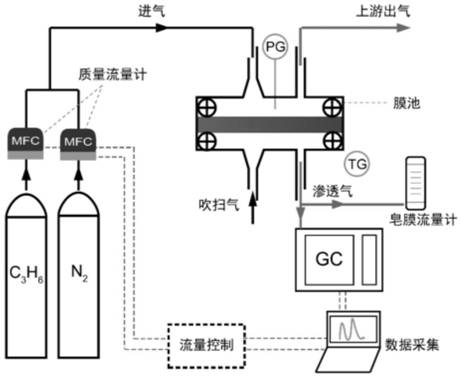

Method used

Image

Examples

Embodiment 1

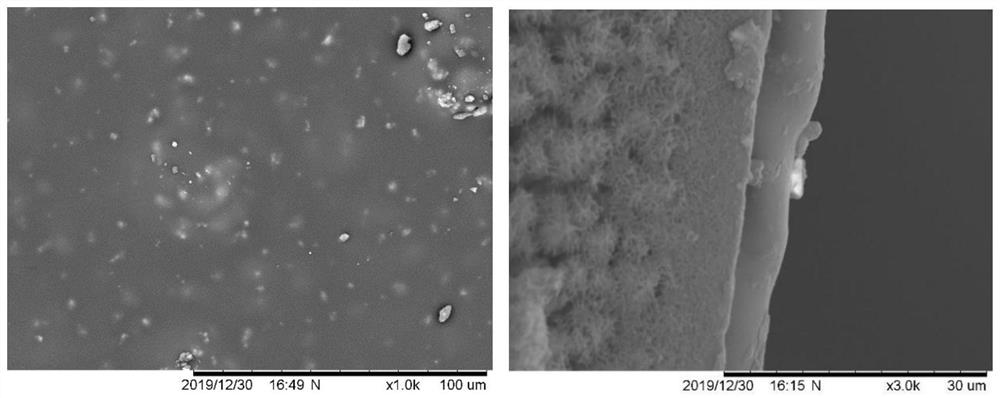

[0041] Add MIL-100(Fe) to 20 grams of n-heptane to form a suspension with a mass concentration of 1%. Take 2 grams of silicone oil with a viscosity of 20000mPa·s and dissolve it in the above suspension, make it fully mixed and dispersed, and then Add 0.2 gram of vinyltrimethoxysilane and 0.06 gram of dibutyltin dilaurate, stir well to obtain the casting solution; use the polyvinylidene fluoride ultrafiltration membrane as the base film, and apply the obtained casting solution evenly to the polyvinylidene fluoride ultrafiltration membrane. on vinyl fluoride ultrafiltration membranes. After standing at room temperature for 24 hours, it was heat-treated in an oven at 60° C. for 4 hours to make it fully crosslinked, and a MIL-100(Fe) filled PDMS gas permeable composite membrane was prepared.

[0042]The prepared composite membrane was used to test the separation performance of mixed gas. When the volume fraction of propane in the mixed gas was 24%, the inlet temperature was 25°C, ...

Embodiment 2

[0044] Add 20 grams of toluene to MIL-100(Fe) to form a suspension with a mass concentration of 5%, and dissolve 2 grams of silicone oil with a viscosity of 100,000 mPa·s into the above suspension, make it fully mixed and dispersed, and then add 0.3 gram of vinyltrimethoxysilane and 0.03 gram of dibutyltin dilaurate, stir well to obtain the casting solution; take the polyimide ultrafiltration membrane as the base film, and evenly coat the obtained casting solution on the polyimide on the ultrafiltration membrane. After standing at room temperature for 24 hours, heat treatment in an oven at 120° C. for 2 hours to make it fully cross-linked to prepare a MIL-100(Fe) filled PDMS gas permeable composite membrane.

[0045] The prepared composite membrane was used to test the separation performance of mixed gas. When the volume fraction of propane in the mixed gas was 24%, the inlet temperature was 25°C, and the inlet pressure was 0.20MPa, the permeation flux was 137.0L·m-2· h-1, th...

Embodiment 3

[0047] Add 20 grams of n-hexane to MIL-100(Fe) to form a suspension with a mass concentration of 10%. Take 2 grams of silicone oil with a viscosity of 5000mPa·s and dissolve it in the above suspension, make it fully mixed and dispersed, and then add 0.15 gram of vinyltrimethoxysilane and 0.1 gram of dibutyltin dilaurate, and stir to obtain a casting solution; the polyetherimide ultrafiltration membrane is used as a base film, and the obtained casting solution is evenly coated on polyetheramide imine ultrafiltration membrane. After standing at room temperature for 24 hours, it was heated in an oven at 60°C for 10 hours to make it fully cross-linked, and a MIL-100(Fe) filled PDMS gas permeable composite membrane was prepared.

[0048] The prepared composite membrane was used to test the separation performance of mixed gas. When the volume fraction of propane in the mixed gas was 24%, the inlet temperature was 25°C, and the inlet pressure was 0.20MPa, the permeation flux was 112....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com