Composited variable-thickness buckling-restrained steel plate shear wall(BR-SPW)

A steel plate shear wall and variable thickness technology, which is applied to walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of increasing the initial defects of the core plate, complex force, unstable energy dissipation capacity, etc., to achieve convenient Force calculation and analysis work, strong applicability, effect of simplified calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

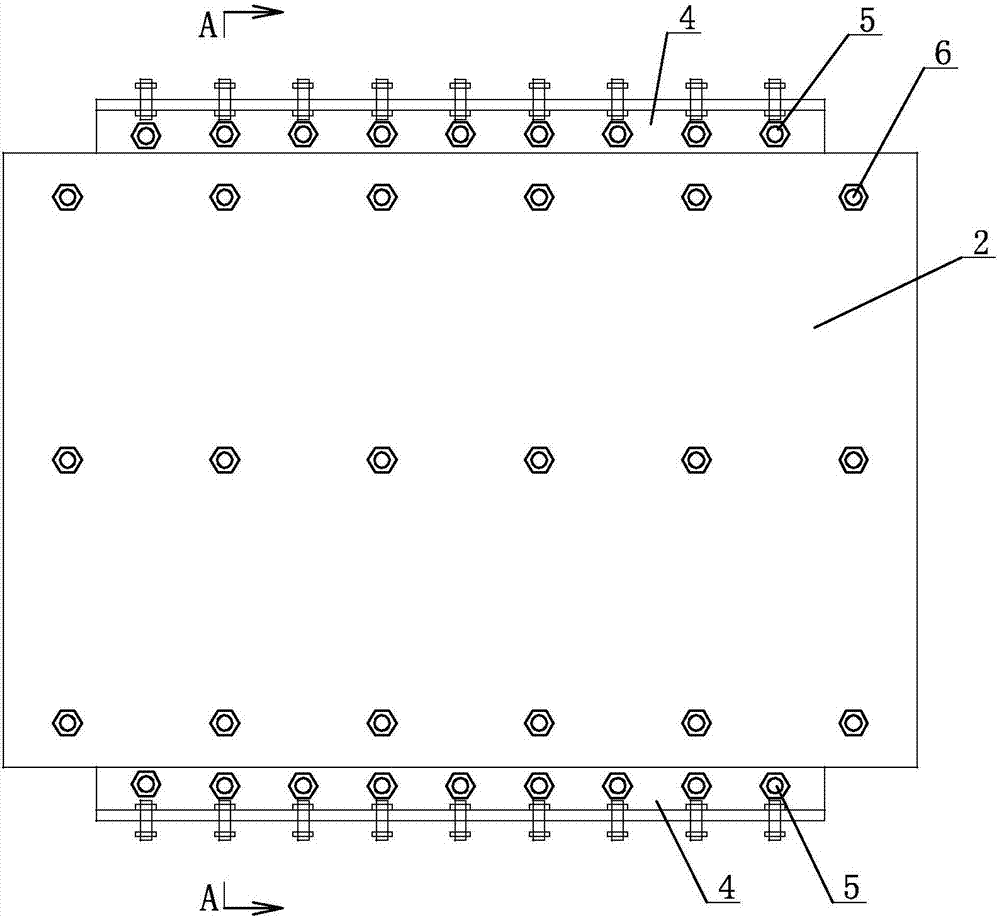

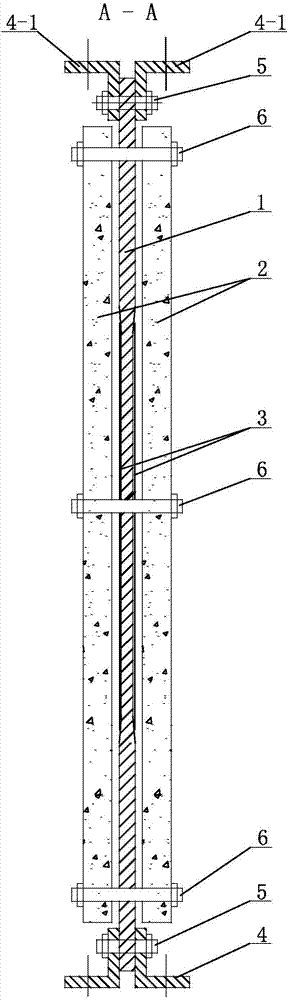

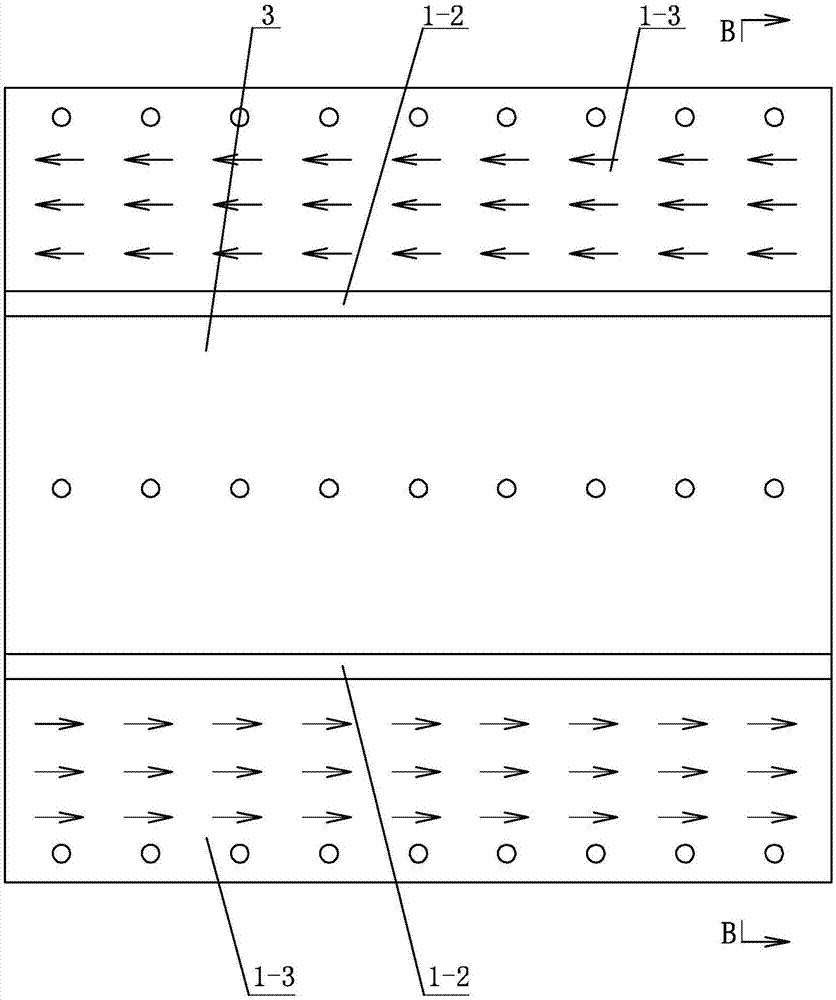

[0015] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment comprises a core plate 1, two concrete slabs 2, two backing plates 3, two connecting pieces 4, several first connecting elements 5 and several second connecting elements 6, the core The plate 1 consists of a thin plate section 1-1, two transition sections 1-2 and two thick plate sections 1-3, and the core plate 1 is distributed from top to bottom into a thick plate section 1-3, a transition section 1- 2. Thin slab section 1-1, transition section 1-2 and thick slab section 1-3, two backing plates 3 are symmetrically arranged on both sides of the thin slab section 1-1, and two concrete slabs 2 are symmetrically arranged on the core slab 1 On both sides, the core plate 1, two backing plates 3 and two concrete slabs 2 constitute a composite buckling-resistant shear wall. Two connectors 4 are respectively arranged at the upper and lower ends of the core plate 1, and each...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination Figure 1 to Figure 5 To describe this embodiment, the thickness of the transition section 1-2 in this embodiment changes uniformly from the thin plate section 1-1 to the thick plate section 1-3. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, in this embodiment, the thickness of the backing plate 3 is one-half of the thickness difference between the thick plate section 1-3 and the thin plate section 1-1, that is, s=0.5×(t1-t2), where : t1 is the thickness of the thick plate section 1-3, t2 is the thickness of the thin plate section 1-1, and s is the thickness of the backing plate 3. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com