Parallel shaft planet shift gearbox

A gearbox and parallel shaft technology, applied in the direction of transmission parts, gear transmissions, components with teeth, etc., can solve the problems of increasing the gear module and increasing the volume of the gearbox.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

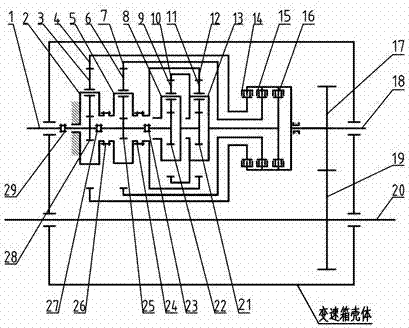

Embodiment 1

[0032] Embodiment 1: A planetary transmission three-gear shifting, output two-way rotating parallel shaft gearbox, which consists of two parts: a planetary transmission shift mechanism and a gear transmission mechanism. The planetary transmission shift mechanism is at the input end of the gearbox, and the gear transmission mechanism is at the output end of the gearbox.

[0033] The planetary transmission shifting mechanism includes: an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear, and the planetary gear is arranged on the planetary carrier. The gear transmission mechanism includes: a driving gear, a driven gear, a driving shaft, and a driven shaft.

[0034] The planetary shifting part is composed of three gears, the first gear and the second gear are forward gears, and the third gear is a reverse gear.

[0035] The first gear of the planetary transmission shifting mechanism is composed of a first-stage planetary transmission, the s...

Embodiment 2

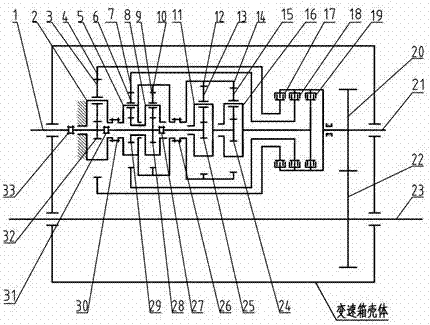

[0040] Embodiment 2: A planetary transmission three-gear shifting, output two-way rotating parallel shaft gearbox, which consists of two parts: a planetary transmission shift mechanism and a gear transmission mechanism. The planetary transmission shift mechanism is at the input end of the gearbox, and the gear transmission mechanism is at the output end of the gearbox.

[0041] The planetary transmission shifting mechanism includes: an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear, and the planetary gear is arranged on the planetary carrier. The gear transmission mechanism includes: a driving gear, a driven gear, a driving shaft, and a driven shaft.

[0042] The planetary shifting part is composed of three gears, the first gear and the second gear are forward gears, and the third gear is a reverse gear.

[0043] The first gear of the planetary transmission shift mechanism is composed of a first-stage planetary transmission, the seco...

Embodiment 3

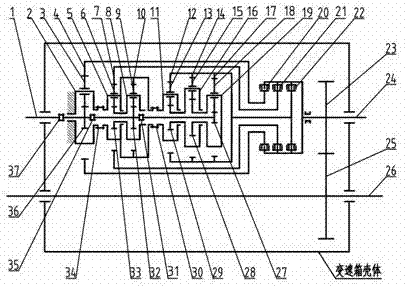

[0048] Embodiment 3: A planetary mechanism with three gears for shifting gears and an output unidirectional rotating parallel shaft gearbox, which consists of two parts: a planetary transmission shift mechanism and a gear transmission mechanism. The planetary transmission shift mechanism is at the input end of the gearbox, and the gear transmission mechanism is at the output end of the gearbox.

[0049] The planetary transmission shifting mechanism includes: an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear, and the planetary gear is arranged on the planetary carrier. The gear transmission mechanism includes: a driving gear, a driven gear, a driving shaft, and a driven shaft.

[0050] The planetary shifting part is composed of three gears, all of which are forward gears.

[0051] The first gear of the planetary shifting mechanism is composed of a first-stage planetary transmission, the second gear is composed of a two-stage planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com