Point laser measuring platform

A measurement platform and point laser technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of improved accuracy and stability, fixed laser sensors, and insufficient flexibility of measurement, so as to avoid external environmental interference and flexibility Good, to achieve the effect of real-time calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

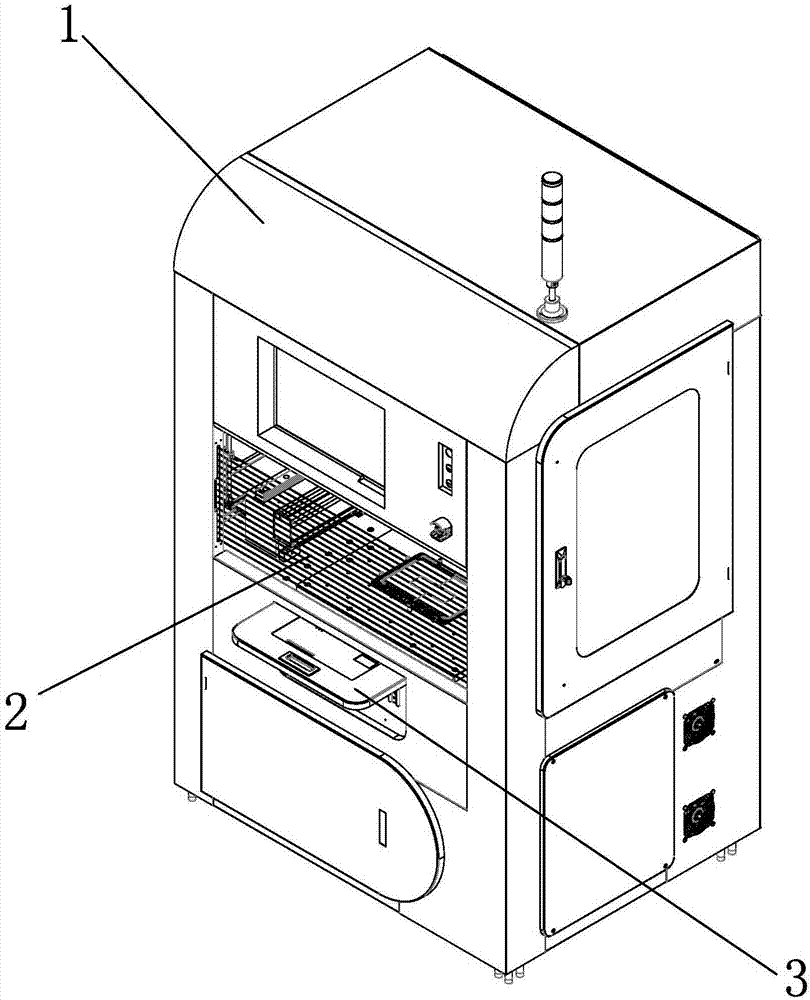

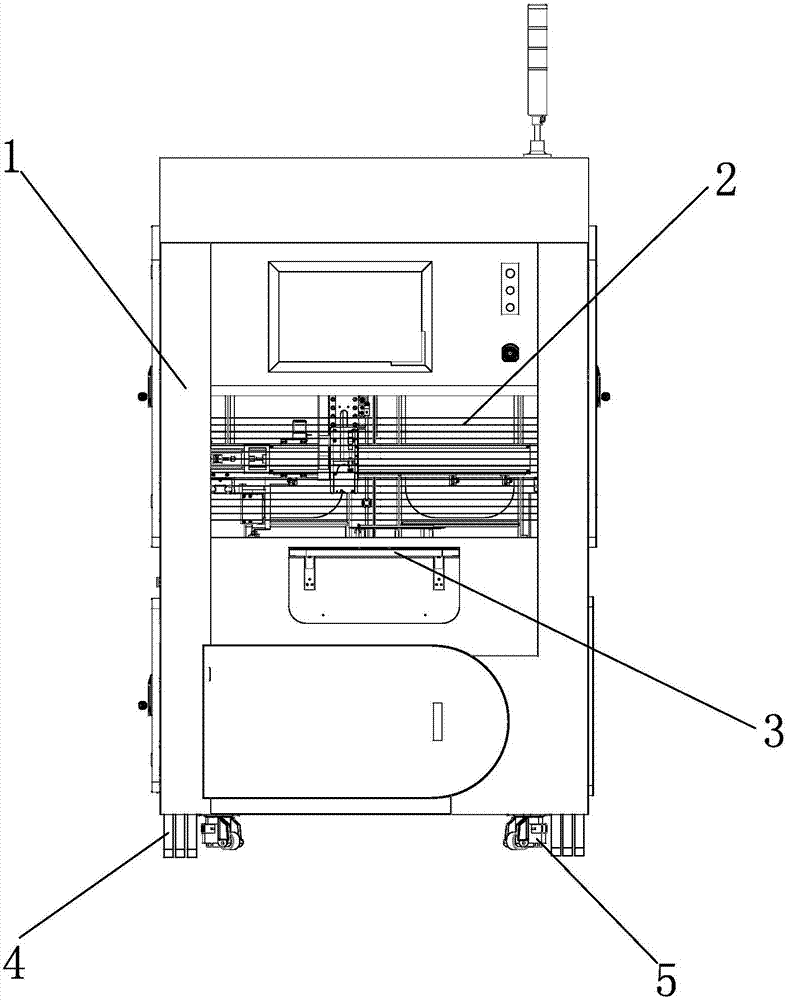

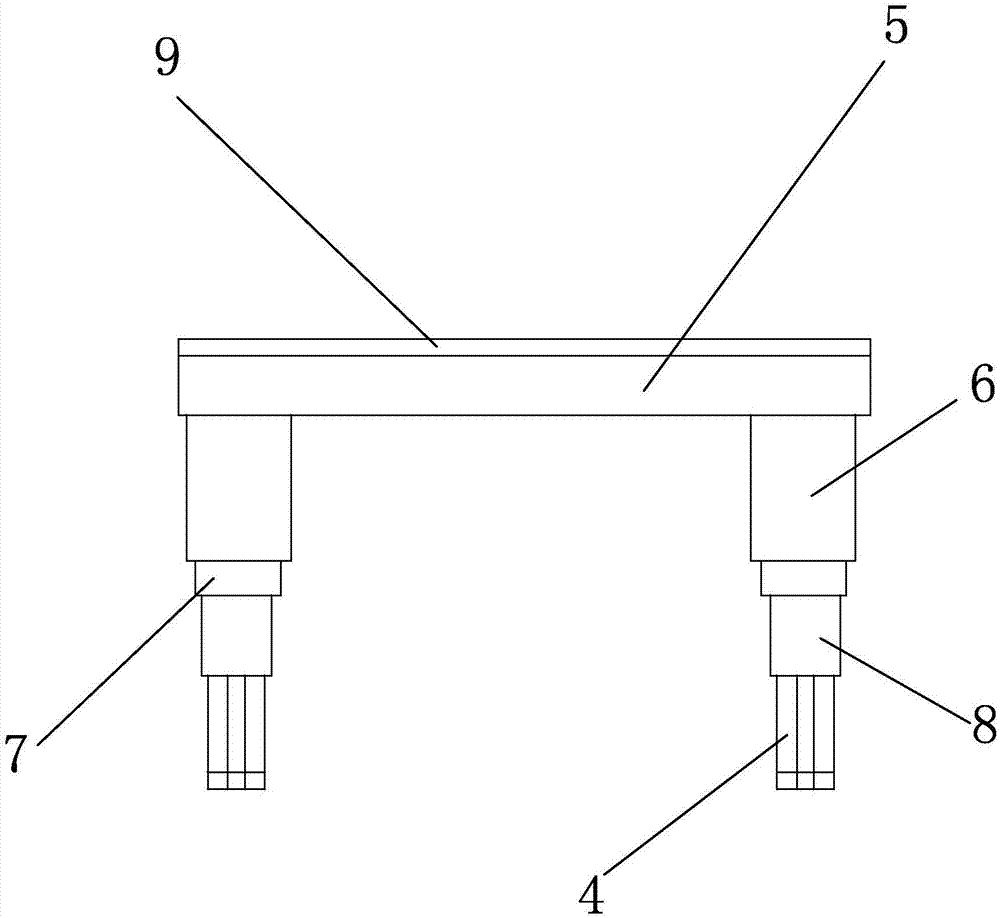

[0030] to combine Figure 1 to Figure 5 , the invention discloses a point laser measurement platform, which uses laser distance measurement to detect the appearance size and appearance curve of a product, and is a high-precision measurement device. The present invention mainly comprises frame and movement. The frame includes a machine table and a casing 1; the machine table is rectangular and is provided with four columns for supporting the movement. The upper part of the column foot is a cylindrical support column 6; a cylindrical shaft sleeve 7 is flexibly connected to the lower end of the support column 6 in a rotatable circumferential direction; the inner wall of the shaft sleeve 7 is provided with an internal thread. The lower part of the column foot is provided with a pneumatic support foot; the pneumatic support foot includes a cylindrical cylinder 8 and three support feet 4 protruding from the cylinder 8 in a triangular distribution. The outer wall of the cylinder 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com