Nonuniform spraying device and method for SCR cold-state mode experiment

A cold-state modeling test and non-uniformity technology, which is applied in the direction of injection devices, liquid injection devices, chemical instruments and methods, etc., to achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

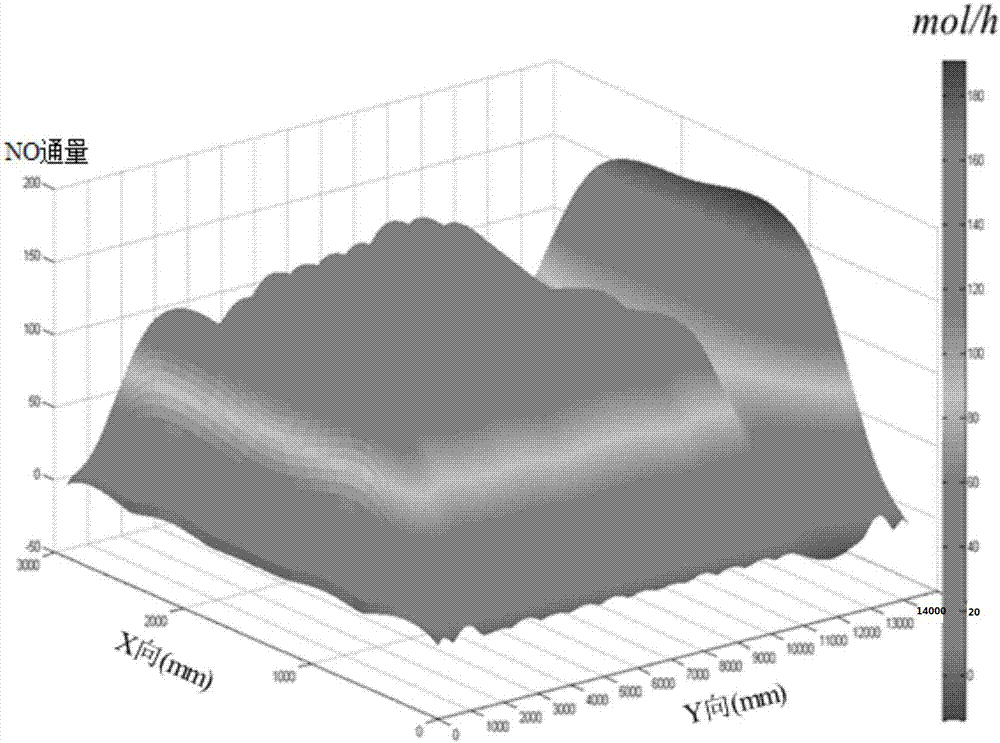

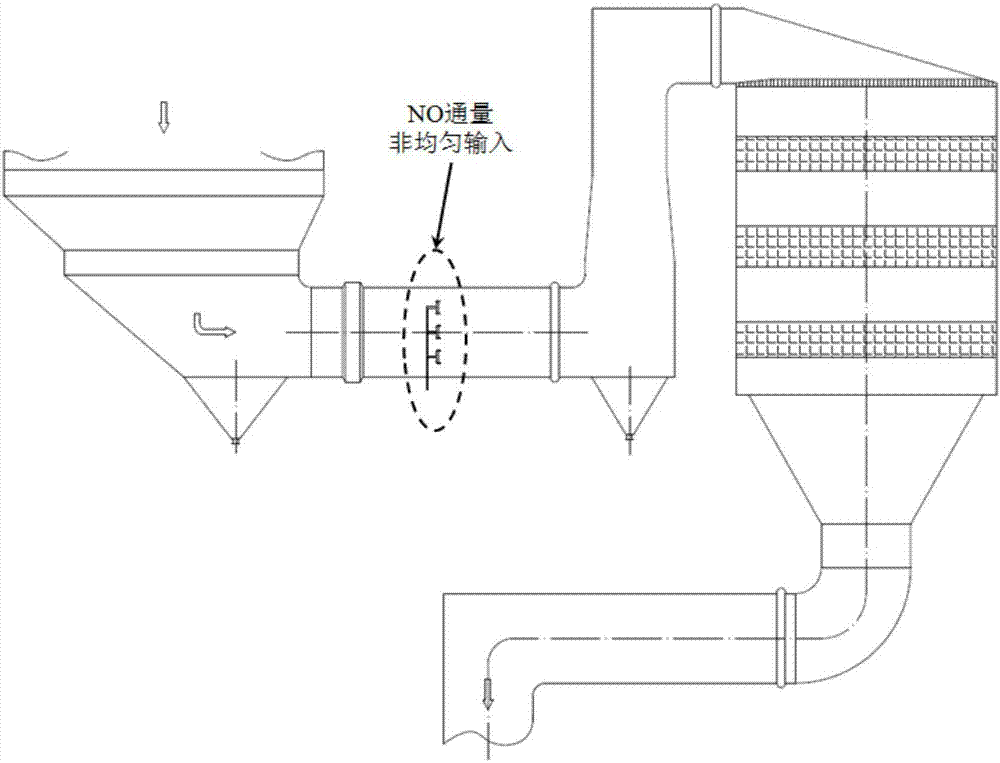

[0030] For the SCR system of a 660MW coal-fired unit, this embodiment provides a non-uniform injection device for SCR cold-state modeling test, which is set in a flue, such as figure 1 As shown, it is installed in the horizontal flue at the inlet of the SCR system. Its section size is 5200mm×8400mm. A total of 4 temporary measuring holes are reserved in the upper part of the horizontal flue at the entrance of the SCR system. NO for SCR cold modeling test x The installation position of the injection device for concentration non-uniformity is consistent with the position of the temporary measuring hole at the entrance of the SCR system. road.

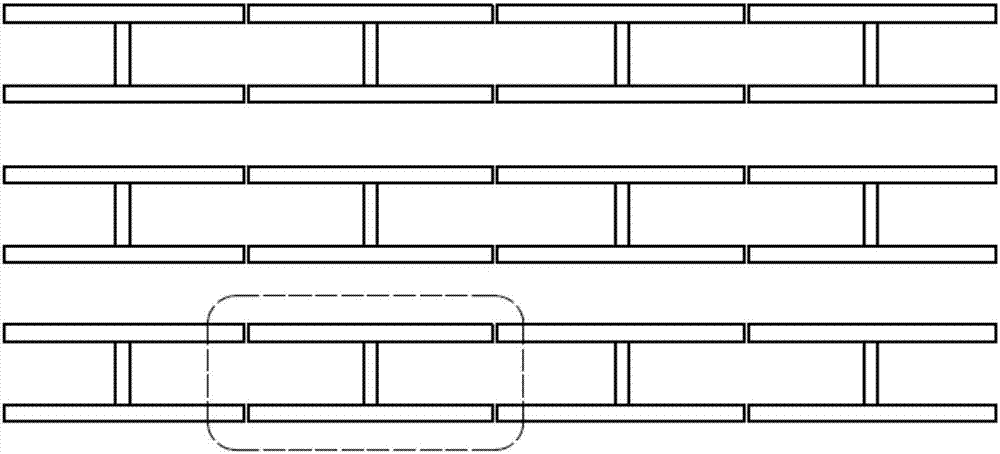

[0031] Such as figure 2 As shown, the device includes: multiple groups of injection subunits with the same structure; one of the injection subunits is framed by the dotted box in the figure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com