Stabilizing fin execution mechanism capable of realizing large fin rotating angle

An actuator and anti-rolling fin technology, which is applied to equipment for reducing the rolling motion of boats, and the field of zero-speed anti-rolling fins, which can solve the problem of not meeting the requirements for anti-rolling of ships, large weight and cabin space, and difficult cabin space layout, etc. problem, to achieve the effect of compact structure, weight reduction, and reduction of cabin space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

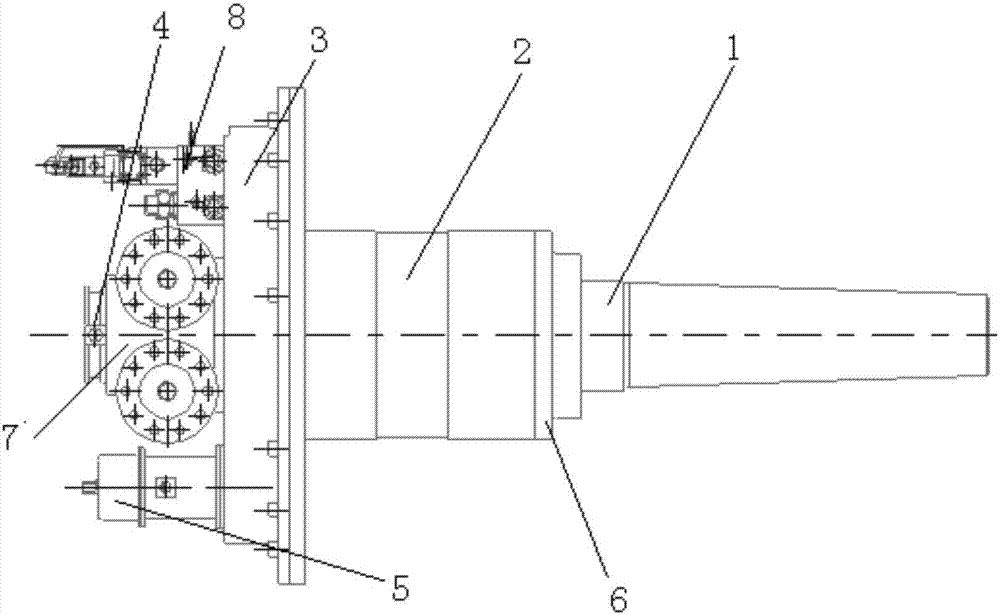

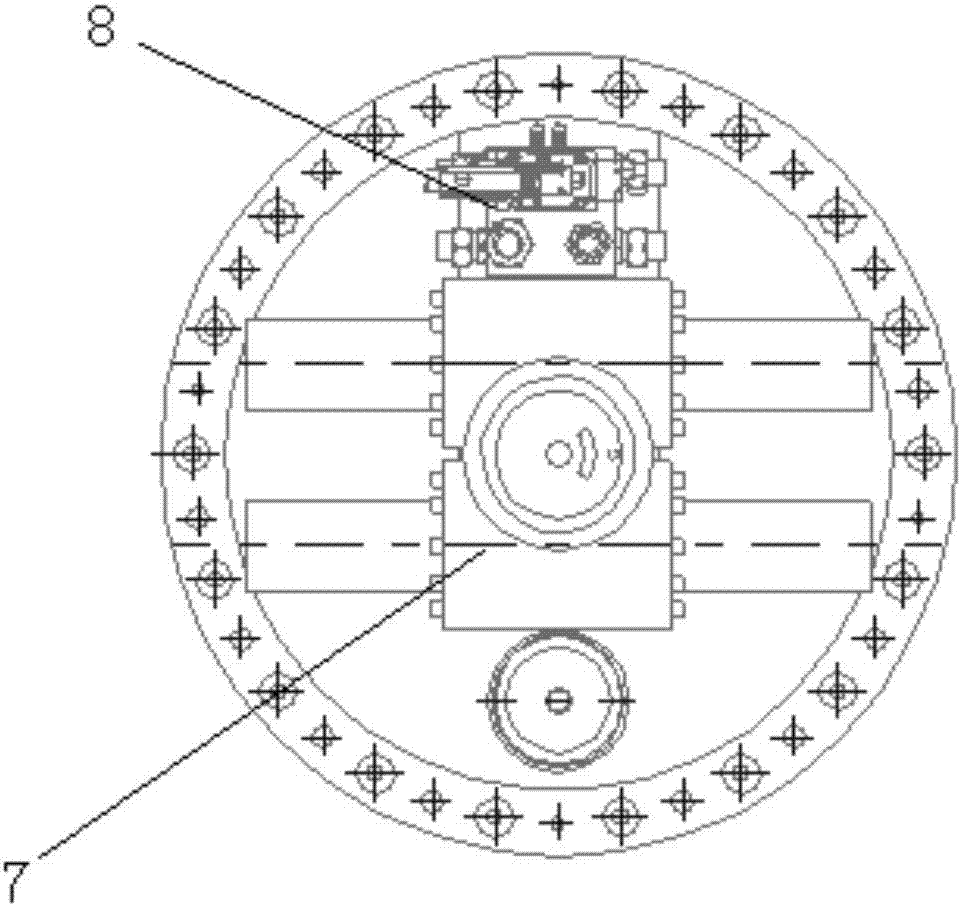

[0021] Such as Figure 1 to Figure 6 As shown, a fin stabilizer actuator that can achieve large fin angle rotation mainly includes a fin shaft group 1, a support seat, a fin angle transmitter 4, a locking mechanism 5, a seawater sealing device 6, a rack and pinion cylinder 7 and Control valve group 8 and so on.

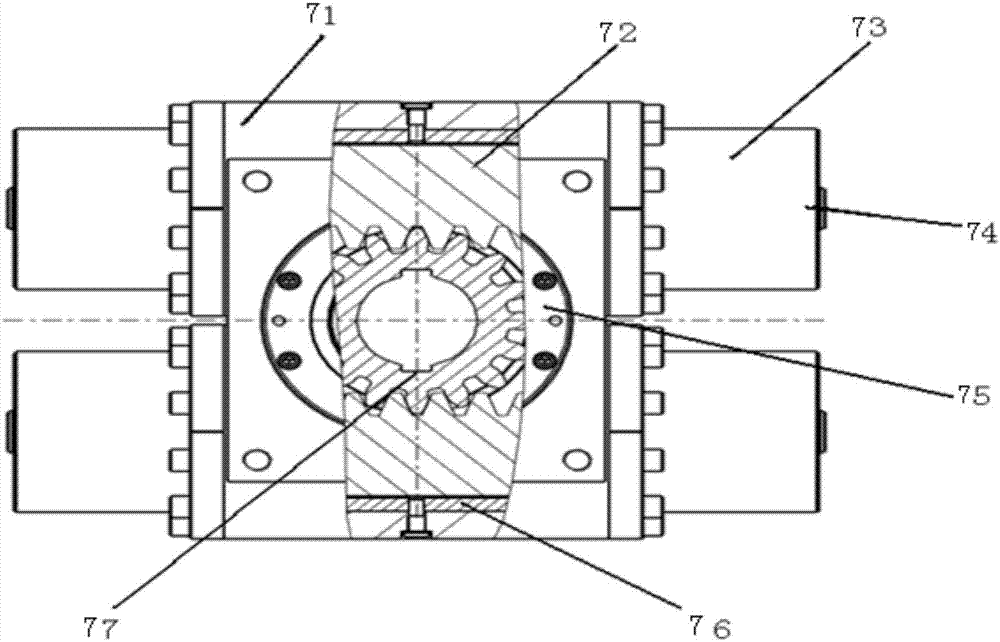

[0022] The rack and pinion cylinder 7 is installed on the front end of the support seat, and is connected with the fin shaft group 1 installed on the rear end of the support seat, and is used to drive the fin shaft group 1 to rotate. The rack and pinion cylinder 7 is composed of a casing 71, a cylindrical rack 72, a cylinder cylinder 73, self-lubricating complete set 76 and gear shaft 77; two cylindrical racks 72 and a gear shaft 77 are integrated in the box body 71, the gear shaft 77 is connected with the fin shaft group 1, and the two cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com