High-strength and high-thermal conductivity polythene for LED (Light Emitting Diode) lamp radiator and preparation method of high-strength and high-thermal conductivity polythene

A LED lamp and polyethylene technology, which is applied in the field of plastic processing, can solve the problems of limiting the application of thermally conductive composite materials and reducing the mechanical properties of composite materials, and achieve the effects of low production cost, improved mechanical strength, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

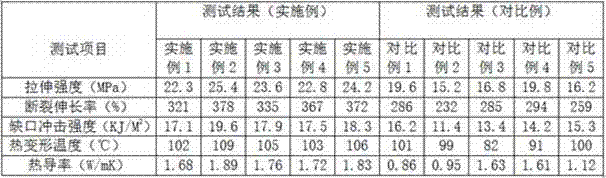

Examples

Embodiment 1

[0025] A high-strength and high-thermal-conductivity polyethylene for LED lamp heat sinks, the basic formula and weight ratio are: 30 parts of ultra-high molecular weight polyethylene, 10 parts of lanthanum oxide, 5 parts of hyperbranched polyamide ester rare earth complex, powdered polyimide 7 parts of amine, 4 parts of SEBS grafted with maleic anhydride, 15 parts of carbon black modified by coupling agent, and 1 part of composite antioxidant.

[0026] The above-mentioned high-strength high-thermal-conductivity polyethylene, its preparation process steps are as follows:

[0027] (1) Weigh the raw materials in the formula according to the weight ratio and add them to the high-mixer, stir for 20 minutes, and mix well;

[0028] (2) Put the mixed raw materials in step (1) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: the temperature range of the barrel of the twin-screw extruder is 230-260 °C, the die temper...

Embodiment 2

[0030] A high-strength and high-thermal-conductivity polyethylene for LED lamp heat sinks, the basic formula and weight ratio are: 40 parts of ultra-high molecular weight polyethylene, 18 parts of cerium oxide, 14 parts of hyperbranched polyamide ester rare earth complex, powdered polyimide 16 parts of amine, 12 parts of SEBS grafted with maleic anhydride, 25 parts of carbon black modified by coupling agent, and 5 parts of composite antioxidant.

[0031] The above-mentioned high-strength high-thermal-conductivity polyethylene, its preparation process steps are as follows:

[0032] (1) Weigh the raw materials in the formula according to the weight ratio and add them to the high-mixer, stir for 40 minutes, and mix well;

[0033] (2) Put the mixed raw materials in step (1) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: the temperature range of the barrel of the twin-screw extruder is 230-260 °C, the die tempe...

Embodiment 3

[0035] A high-strength and high-thermal-conduction polyethylene for LED lamp heat sinks, the basic formula and weight ratio are: 35 parts of ultra-high molecular weight polyethylene, 14 parts of cerium oxide, 9 parts of hyperbranched polyamide ester rare earth complex, powdered polyimide 12 parts of amine, 8 parts of maleic anhydride grafted SEBS, 20 parts of carbon black modified by coupling agent, and 3 parts of composite antioxidant.

[0036] The above-mentioned high-strength high-thermal-conductivity polyethylene, its preparation process steps are as follows:

[0037] (1) Weigh the raw materials in the formula according to the weight ratio and add them to the high mixer, stir for 25 minutes, and mix well;

[0038] (2) Put the mixed raw materials in step (1) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: the temperature range of the barrel of the twin-screw extruder is 230-260 °C, the die temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com