Drying tower and natural gas purification system

A drying tower and desiccant technology, applied in gas fuel, petroleum industry, fuel, etc., can solve the problems of high production cost of drying tower, low durability of drying tower, high failure rate and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

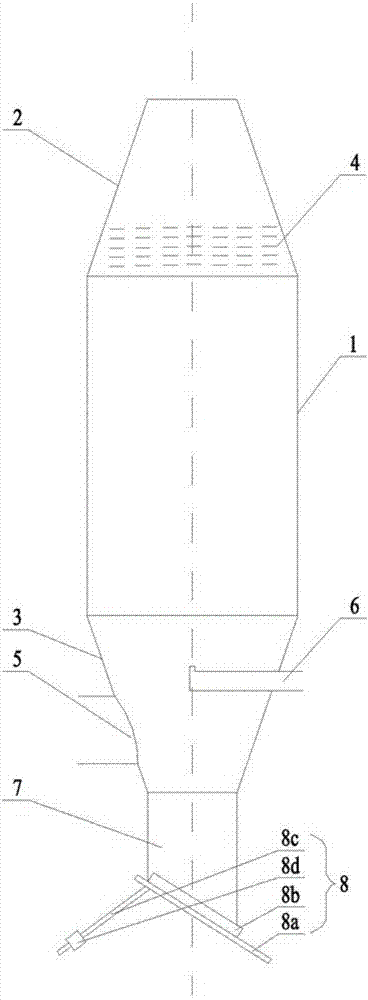

[0017] A drying tower and a natural gas purification system, the drying tower can contain a desiccant (13), and is characterized in that it includes an inner cavity (11), an outlet pipe (12) and an inlet pipe (15) for inputting natural gas, the The inner port of the outlet pipe (12) is communicated with the inner cavity (11), and the filter cover (14) capable of filtering the desiccant (13) is installed at the inner port of the outlet pipe (12); The height difference between the level of the outlet pipe (12) and the level of the lowest point of the inner cavity (11) is L1, the total height of the inner cavity (11) is L2, and L1 / L2≤0.2; The height difference between the level of the inlet pipe (15) and the level of the apex of the inner chamber (11) is L3, L3 / L2≤0.2.

[0018] The drying tower includes an inner chamber 11 and an outlet pipe 12 , the inner port of the outlet pipe 12 communicates with the inner chamber 11 , and a filter cover 14 capable of filtering desiccant 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com