Cantilever unloading platform

A technology of unloading platform and cantilever, which is applied in the processing of building materials, construction, building structure, etc. It can solve the problems of safety hazards, falling objects, limited area and height of unloading platform, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

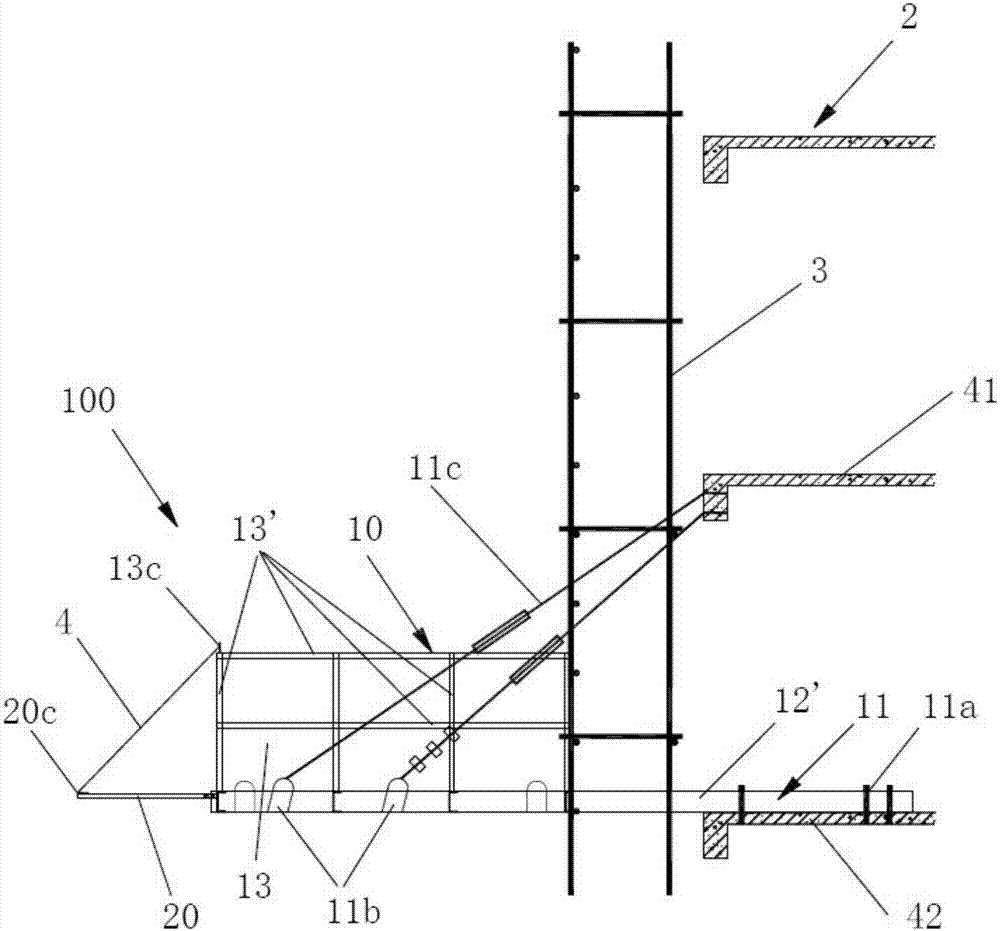

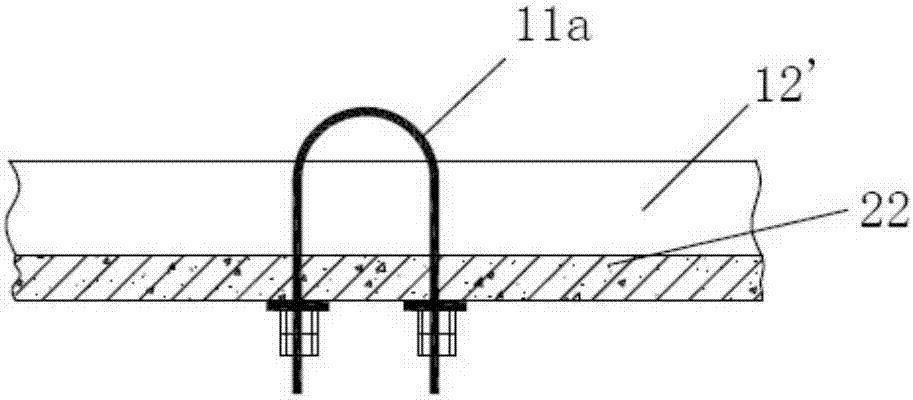

[0020] like figure 1 , 2 As shown, the cantilever unloading platform 100 of the preferred embodiment of the present invention includes a main body 10 , and the main body 10 includes a platform frame 11 . The platform frame 11 is suspended from the superstructure floor 41 of the building 2 , passes through the outer frame 3 and protrudes from the outer frame 3 . One end of the platform frame 11 is fixed on the superstructure floor 41 through a plurality of Φ20 steel bar pressure rings 11a, and the other end is provided with a Φ16 round steel wire rope oblique stay ring 11b, and is connected with the lower structure floor 42 through a Φ18 unloading steel wire rope 11c . like image 3 As shown, the two legs of the Φ20 reinforcement ring 11a pass through the platform frame 11 and the substructure floor 42, the lower part is threaded, and fixed to the substructure floor 42 with double nuts.

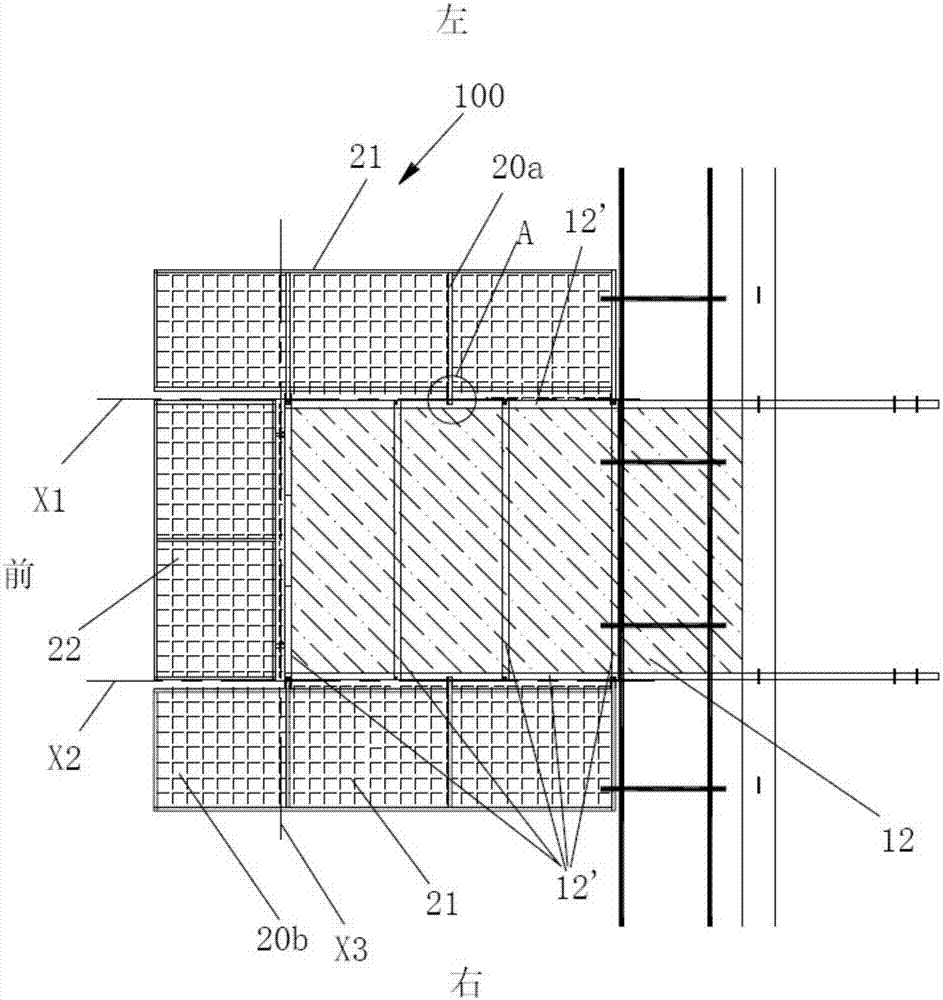

[0021] The platform frame 11 includes a bottom frame 12' and a side protection frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com