Lifting platform for glass curtain wall maintenance

A glass curtain wall and lifting platform technology, which is applied in the field of construction engineering, can solve problems such as inconvenient construction operations and inability to adjust the center of gravity, and achieve the effects of avoiding falling objects, ensuring safety, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

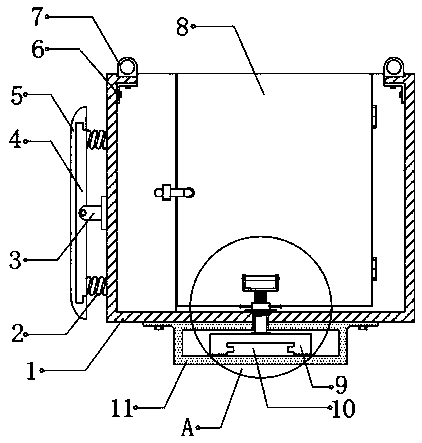

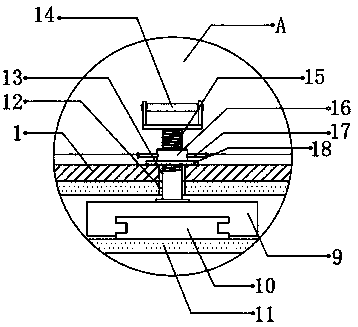

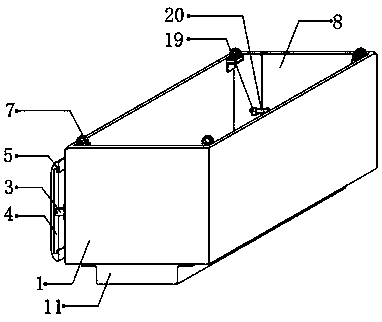

[0031] refer to Figure 1-5 , a lifting platform for glass curtain wall maintenance, including a box body 1 and hanging rings 7, the four hanging rings 7 are respectively fixedly connected to the four corners of the inner wall of the top of the box body 1, and a second sliding hole 13 is provided at the middle position of the bottom of the box body 1 , and the middle position of the outer wall of the bottom of the box body 1 is connected with the box body 11 by bolts, and the middle position of the top of the box body 11 is provided with a first sliding hole 12, and the first sliding hole 12 is matched with the second sliding hole 13, the box The inner wall of the bottom of the body 11 is fixedly connected with the electric slide rail 10, and the top of the electric slide rail 10 is slidably connected with the counterweight 9, and the middle position of the top of the counterweight 9 is fixedly connected with the threaded post 15, and the top of the threaded post 15 passes thro...

Embodiment 2

[0040] refer to Figure 6 , a lifting platform for glass curtain wall maintenance. Compared with Embodiment 1, the middle part of the inner wall of one side of the box body 1 is connected with a storage box 22 by bolts, and the top of the storage box 22 is set as an opening, and the box body 1 is close to the A baffle 23 is hinged on the top of one side of the storage box 22 , and a cable 24 is fixedly connected between the middle position of the top of the baffle 23 and the inner wall of the box body 1 .

[0041] Working principle: The storage box 22 is the same as holding tools and accessories for maintenance. The baffle 23 is sealed on the top of the storage box 22, which can play a blocking role when taking tools or accessories to avoid falling objects from high altitude. The baffle 23 Rotation can be realized to cooperate with the process of taking the tool, and the pulling force exerted by the cable 24 positions the baffle 23 so that the baffle 23 can hover in a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com