Light Module

An optical module and optical technology, applied in the field of optical modules, can solve the problems of impracticality, expensive processing and manufacturing failure, and complex automated production line manufacturing, and achieve the effects of simple fixation, simplified assembly, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

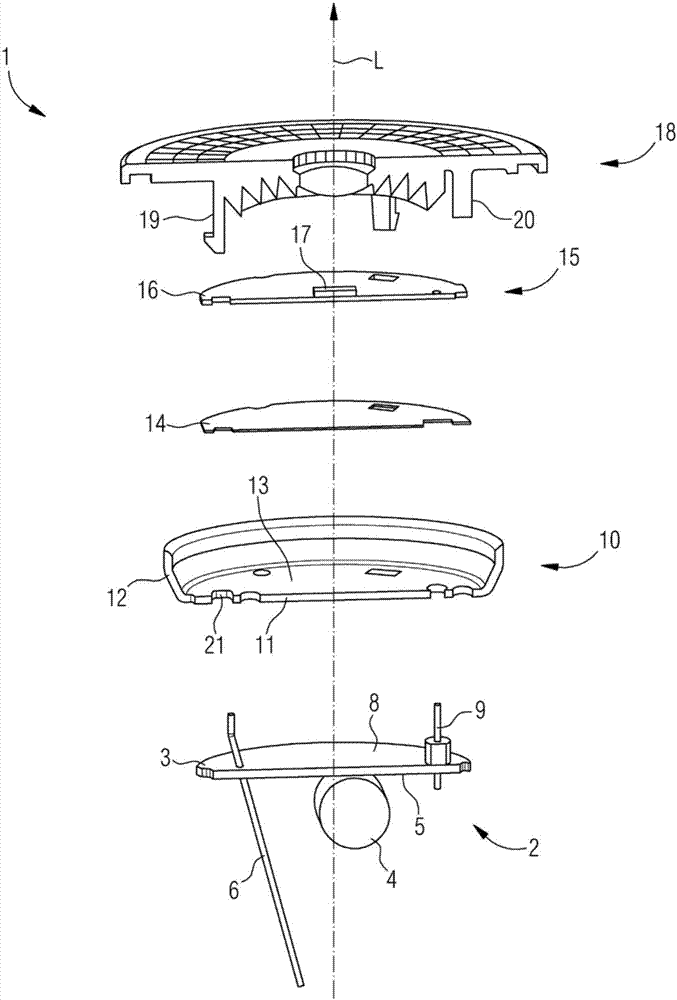

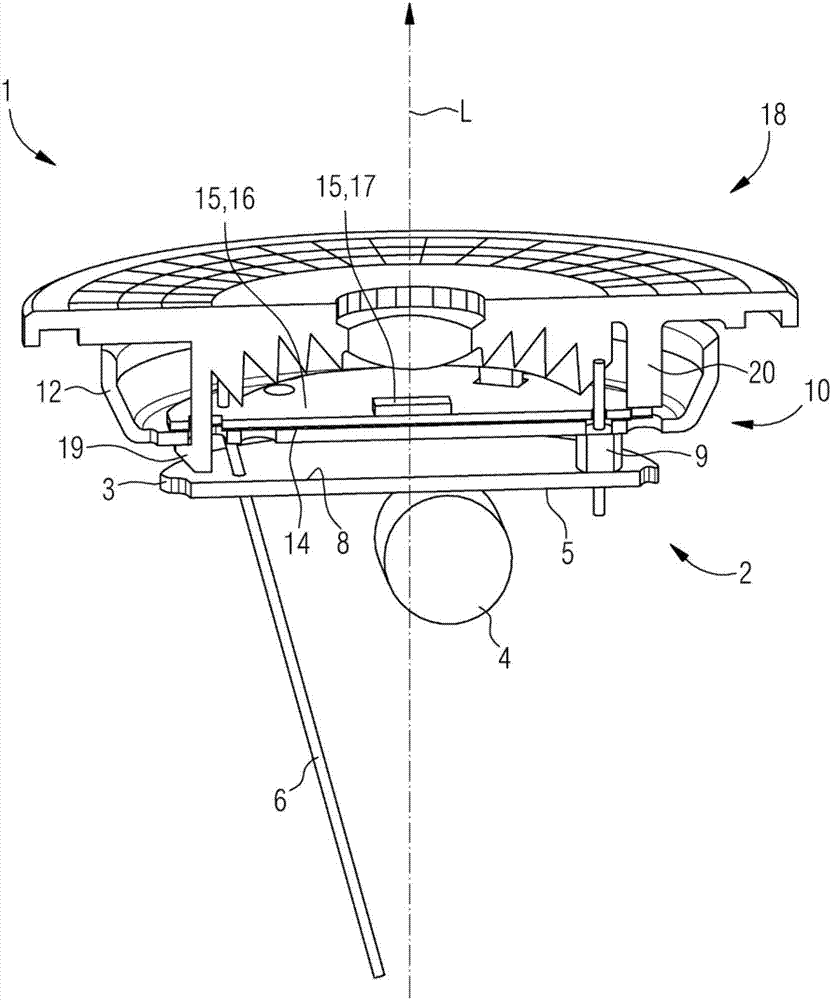

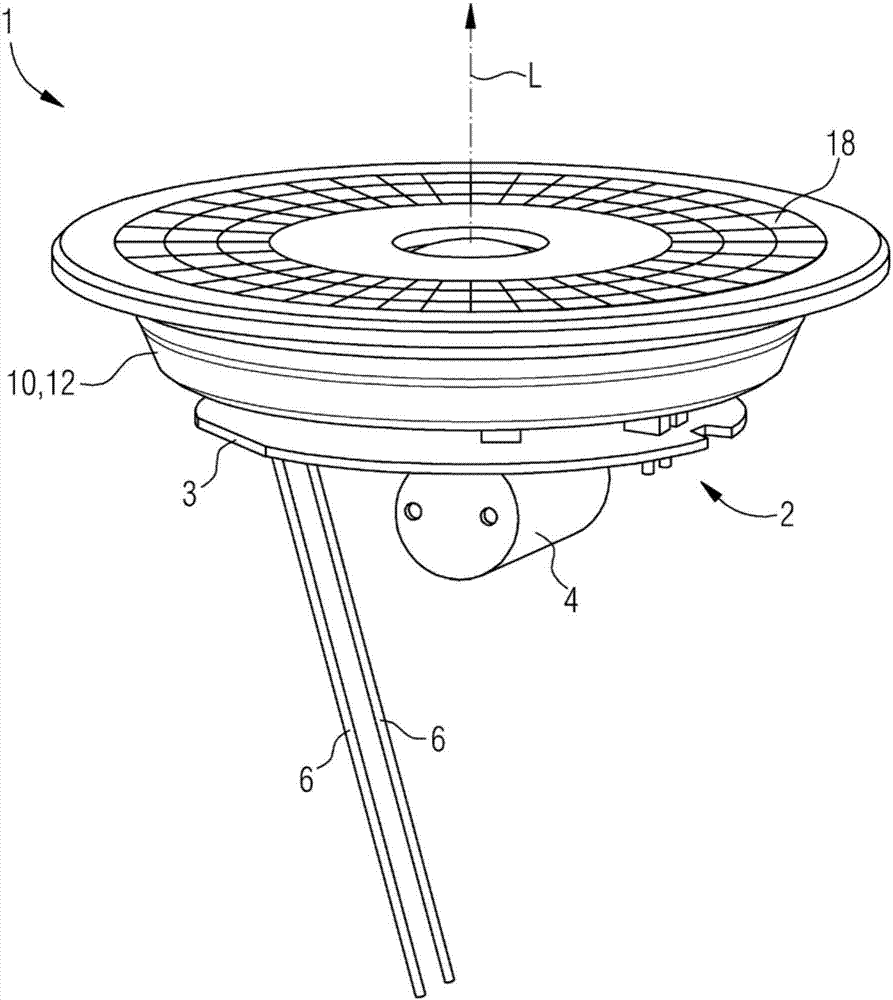

[0044] figure 1 Shown to be assembled into optical module 1 (referring to figure 2 or image 3 ) side view of a single element. These elements comprise a driver 2 with a driver circuit board 3 perpendicular to the longitudinal axis L. Electrical and / or electronic components 4 are arranged on the driver circuit board, ie in particular on the rear side 5 . Conductive contact cables 6 protrude from the back side 5, ie at the contact portion towards the contact pin 7 (see Figure 5 ) direction. The front side 8 of the driver circuit board 3 is equipped with solder pins or feet 9 protruding forward (in the longitudinal direction L).

[0045] The other part is a shell-shaped cooling body 10 having a disc-shaped planar bottom 11 oriented perpendicular to the longitudinal axis L and lateral walls 12 adjoining transversely forward.

[0046] A TIM film 14 is arranged on the front face 13 of the base 11 .

[0047] Arranged in front of the TIM film 14 is a light emitter 15 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com