Difunctional oxygen catalyst cobalt/cobaltosic oxide/nitrogen carbon composite material and preparation method thereof

A technology of tricobalt tetroxide and oxygen catalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc. It can solve the problems of high cost of oxygen catalyst and low catalytic activity, and achieve The effect of excellent catalytic activity, large limiting current density, excellent bifunctional activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

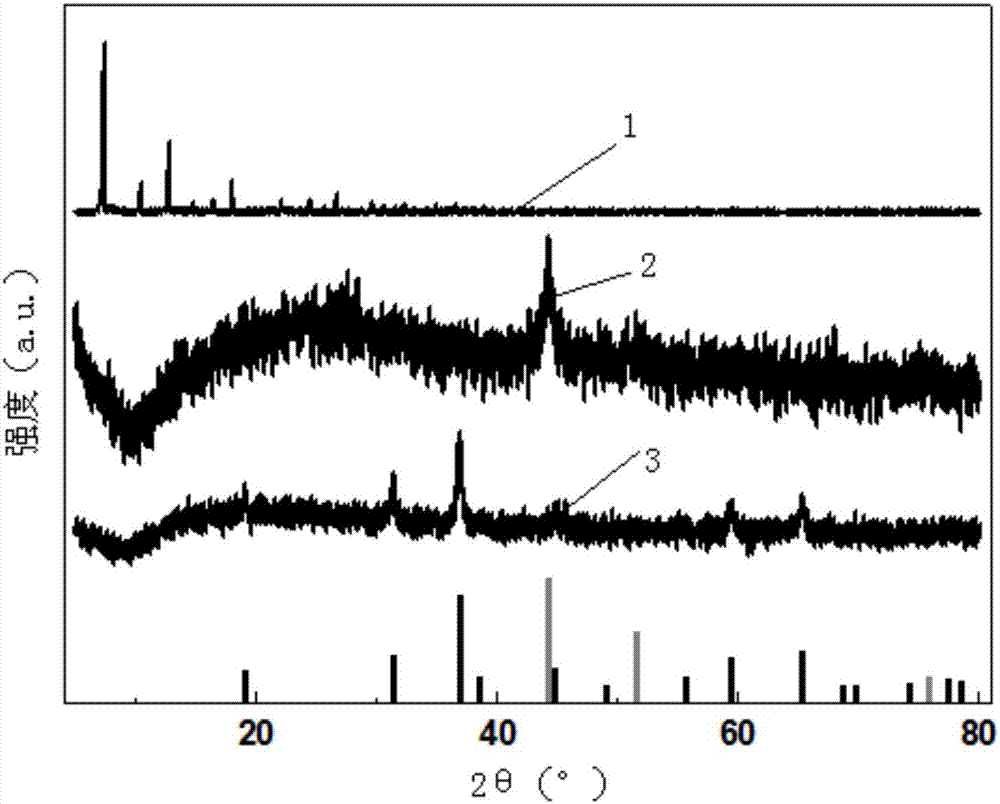

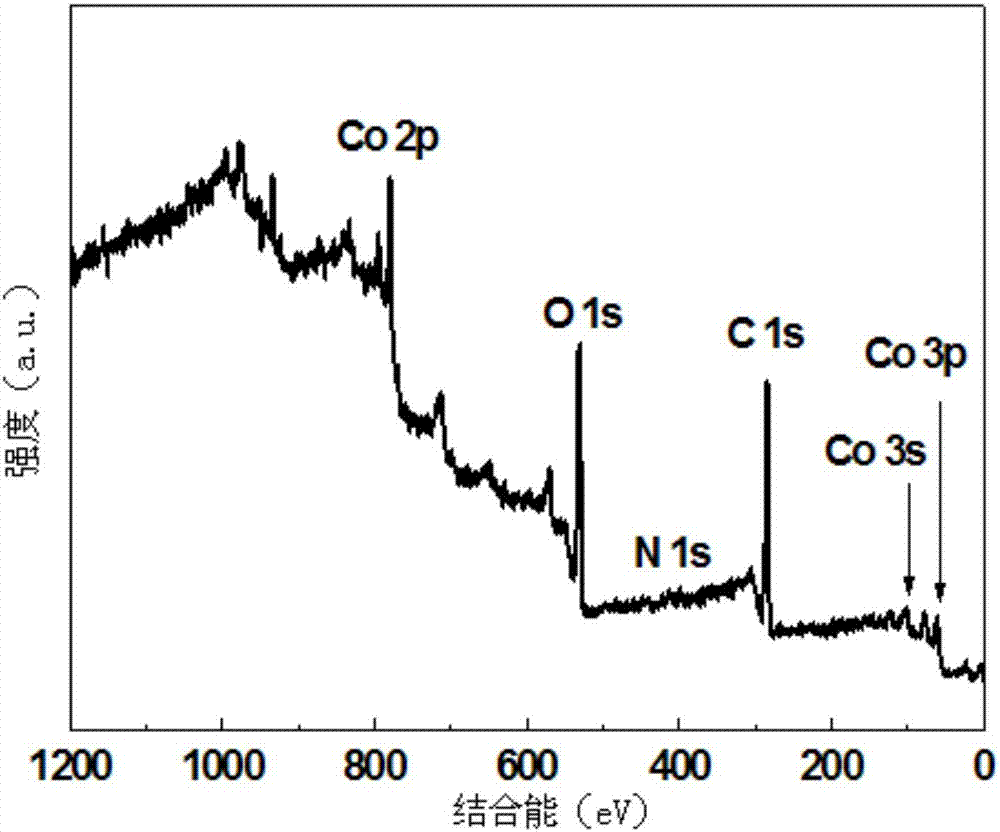

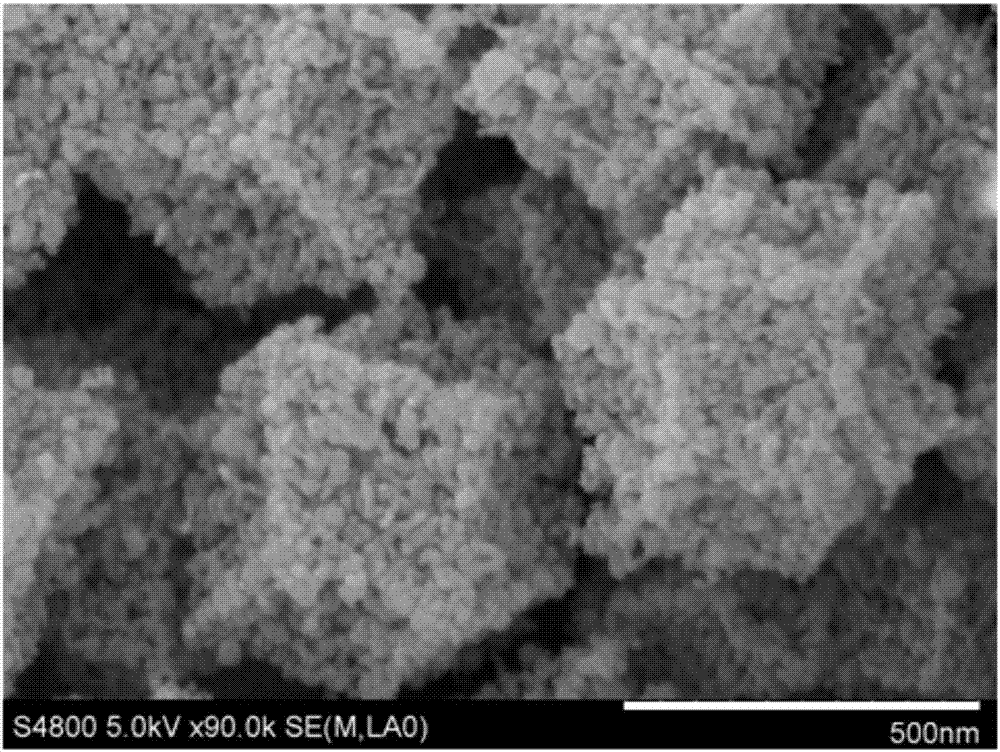

[0024] Embodiment 1: A dual-functional oxygen catalyst cobalt / cobalt tetroxide / nitrogen-carbon composite material in this embodiment is a dual-functional oxygen catalyst cobalt / cobalt tetroxide / nitrogen-carbon composite material with rhombic dodecahedral morphology.

specific Embodiment approach 2

[0025] Specific embodiment two, the preparation method of a kind of bifunctional oxygen catalyst cobalt / cobalt tetroxide / nitrogen-carbon composite material of the present embodiment is carried out according to the following steps:

[0026] 1. Preparation of ZIF-67 precursor: ① Co(NO 3 ) 2 ·6H 2 O is dissolved in methanol to give Co(NO 3 ) 2 solution; ②dissolve 2-methylimidazole in methanol to obtain 2-methylimidazole solution; ③under the condition of stirring speed of 150r / min~200r / min, dissolve 2-methylimidazole solution at 5mL / min~ Add dropwise to Co(NO 3 ) 2 solution, aged at room temperature for 20h to 24h, and obtained a purple precipitate of ZIF-67 after suction filtration; ④ washed the purple precipitate of ZIF-67 with methanol for 2 to 4 times, and then placed in an oven at a temperature of 50 to 70°C Under the condition of drying overnight, obtain the ZIF-67 precursor;

[0027] Co(NO 3 ) 2 Co(NO 3 ) 2 ·6H 2 The ratio of the mass of O to the volume of metha...

specific Embodiment approach 3

[0032]Specific embodiment three: the difference between this embodiment and specific embodiment two is: the Co(NO 3 ) 2 Co(NO 3 ) 2 ·6H 2 The ratio of the mass of O to the volume of methanol is 0.498g:50mL. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com