Modular paper material shaping device

A setting device and modular technology, applied in the field of modular paper setting device, can solve the problem of inability to realize automatic operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

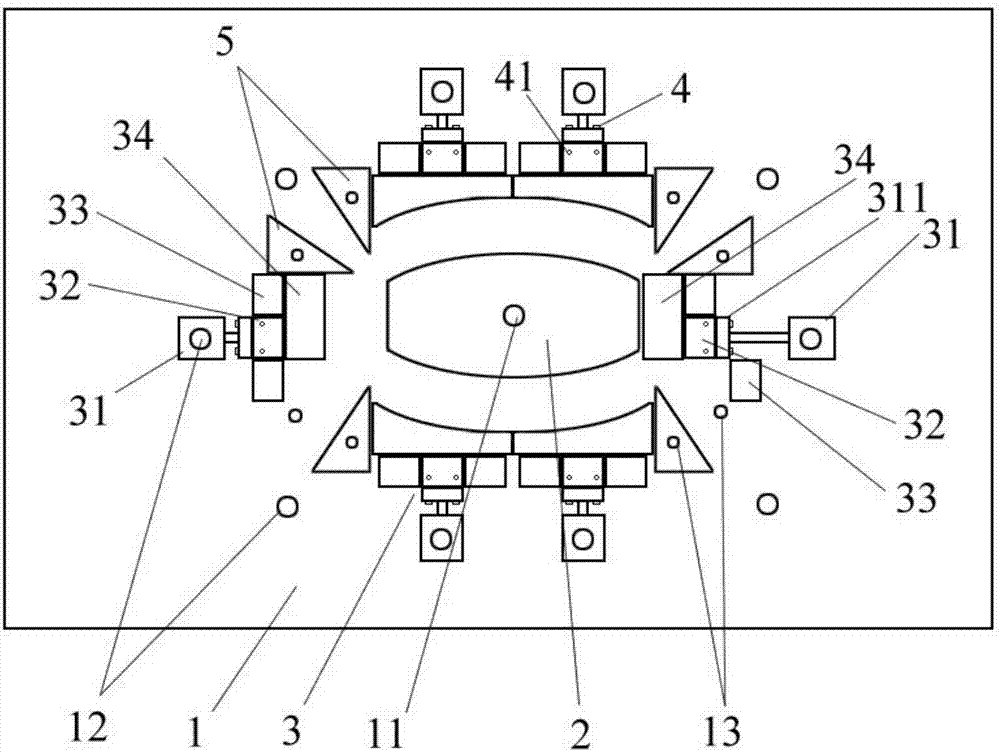

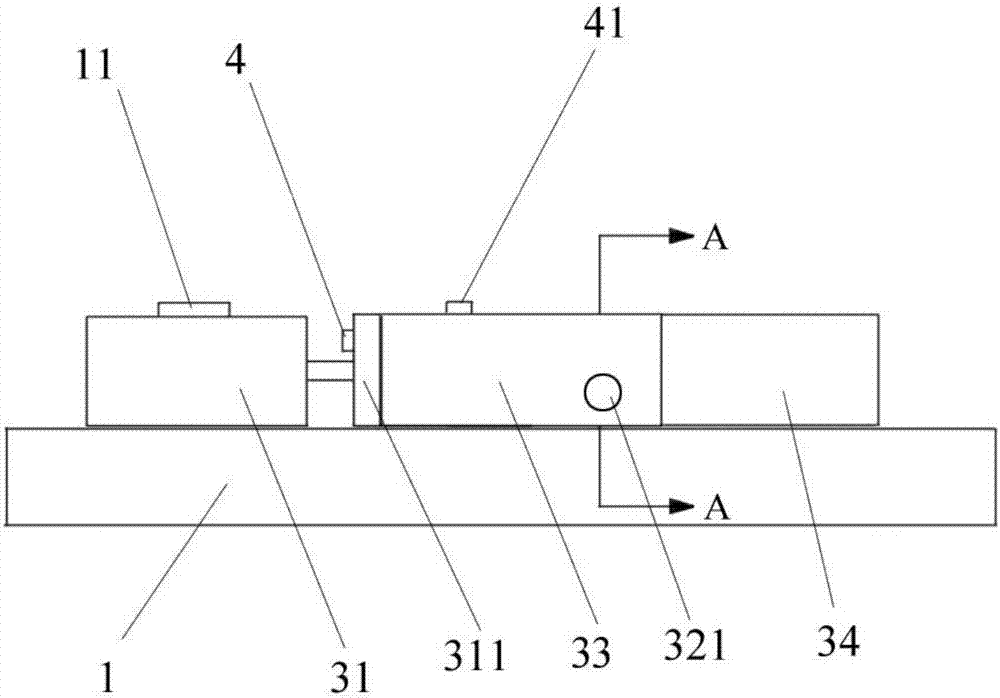

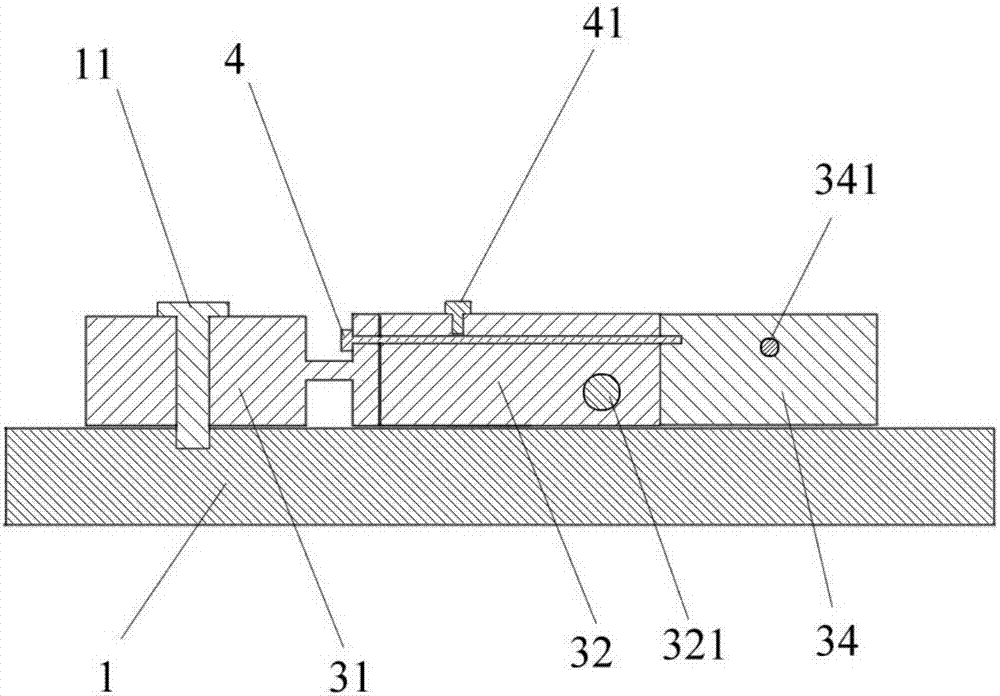

[0029] Such as figure 1 As shown, the present embodiment is a modularized paper material setting device, wherein a central hole 11 is provided on the workbench 1, and installation holes 12 are provided around the center hole 11 (generally, the number of installation holes is 8 to 12 according to the size of the workbench, And equidistant distribution, of course, the more the number of mounting holes, the more flexible the assembly method), the half of the central hole 11 is provided with an auxiliary hole 13 between the mounting holes 12. The center hole 11 is fixed with a fixed sizing block 2 by bolts; the power part 31 (cylinder) of the heating and shaping device 3 is fixed by bolts on a suitable mounting hole 12, and the stroke part 311 of the power part 31 is connected with a heat-insulating connector 32 , heat insulating widening pieces 33 are arranged on both sides of the heat insulating connecting piece 32, select a suitable heating shaping block 34 to connect behind th...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, except that the heat insulating connector 32 cooperates with the synchronous rod 321 between the heat insulating widening parts 33 on both sides, and the heat insulating connecting part 32 and each heat insulating widening part 33 There is a separate synchronous rod 321 inside, the synchronous rod 321 is an iron rod, the outer side of the synchronous rod 321 is wound with a coil 322, the coil 322 is connected to an external power supply, and the power supply is controlled by the controller to realize the heat insulation connector 32 and Combination or separation of thermal insulation widening member 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com